Your position:

Home > Products > Shotcrete Gunite Machine

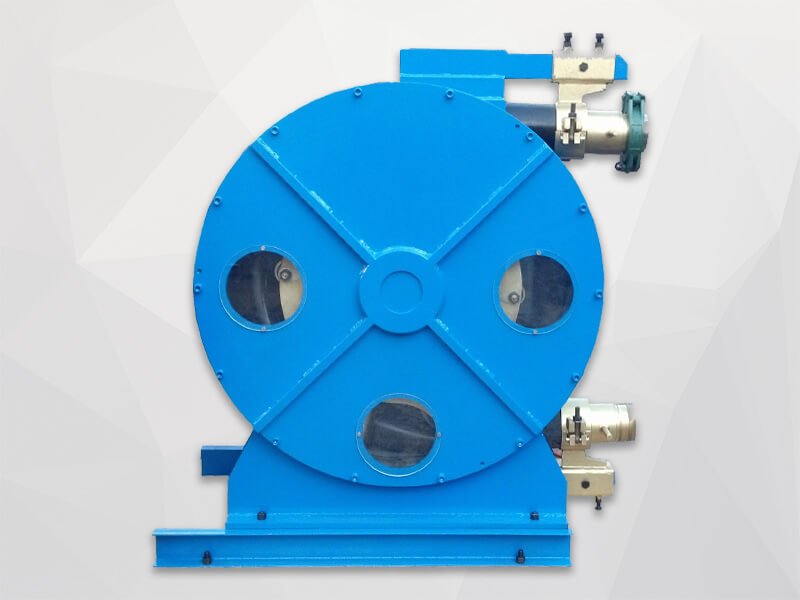

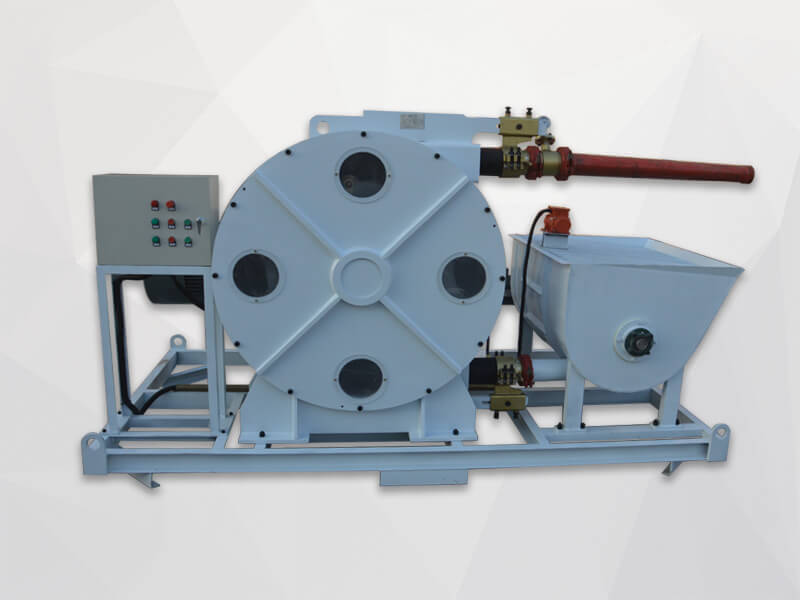

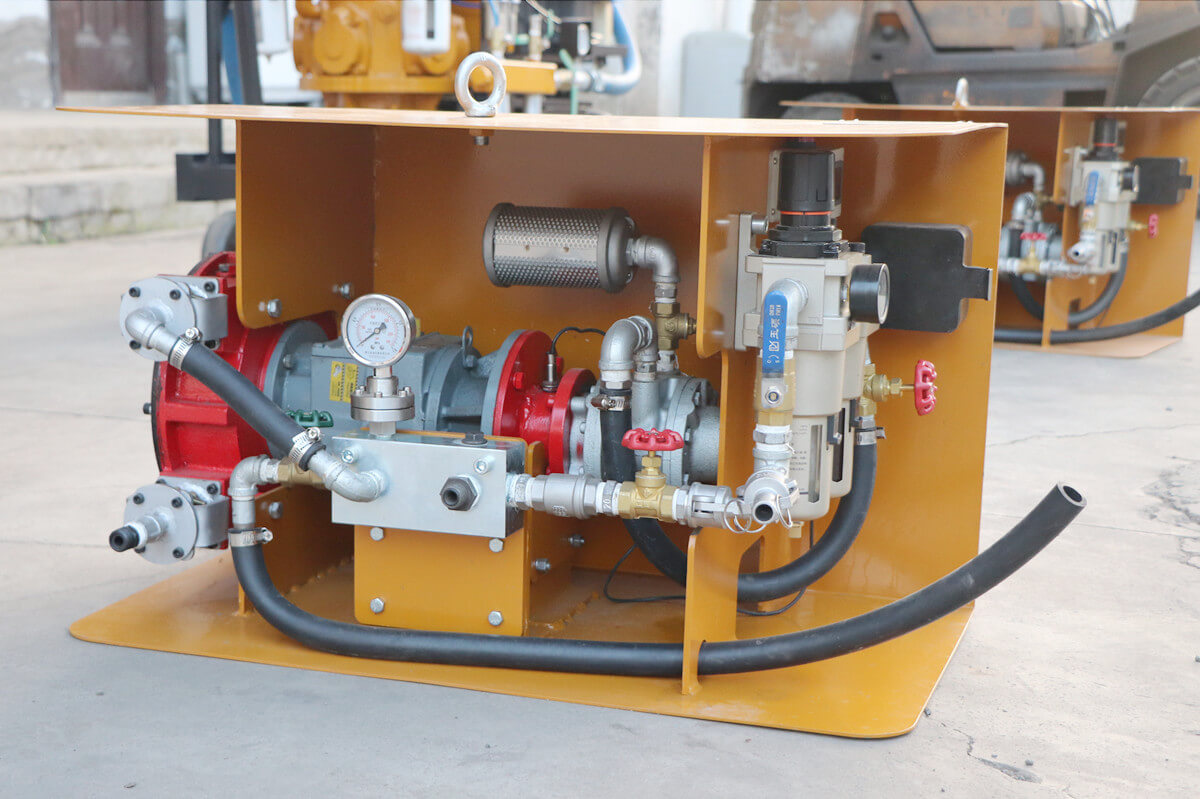

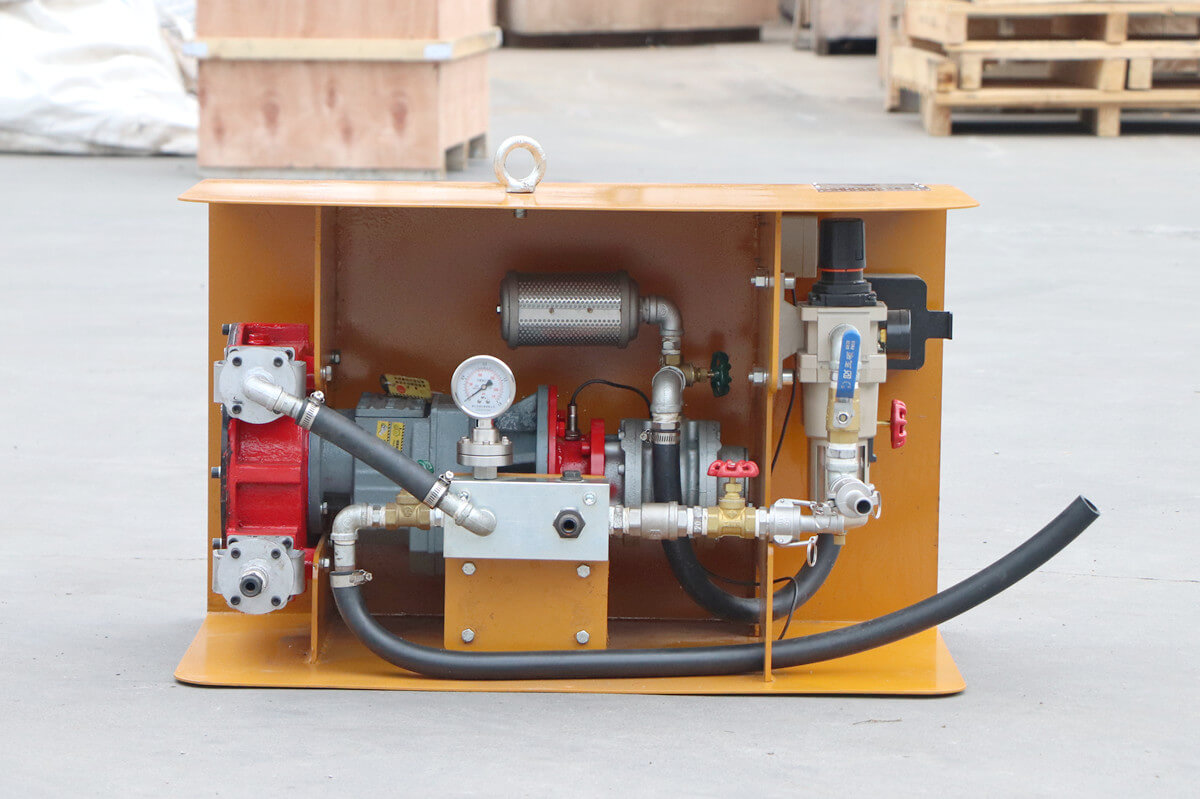

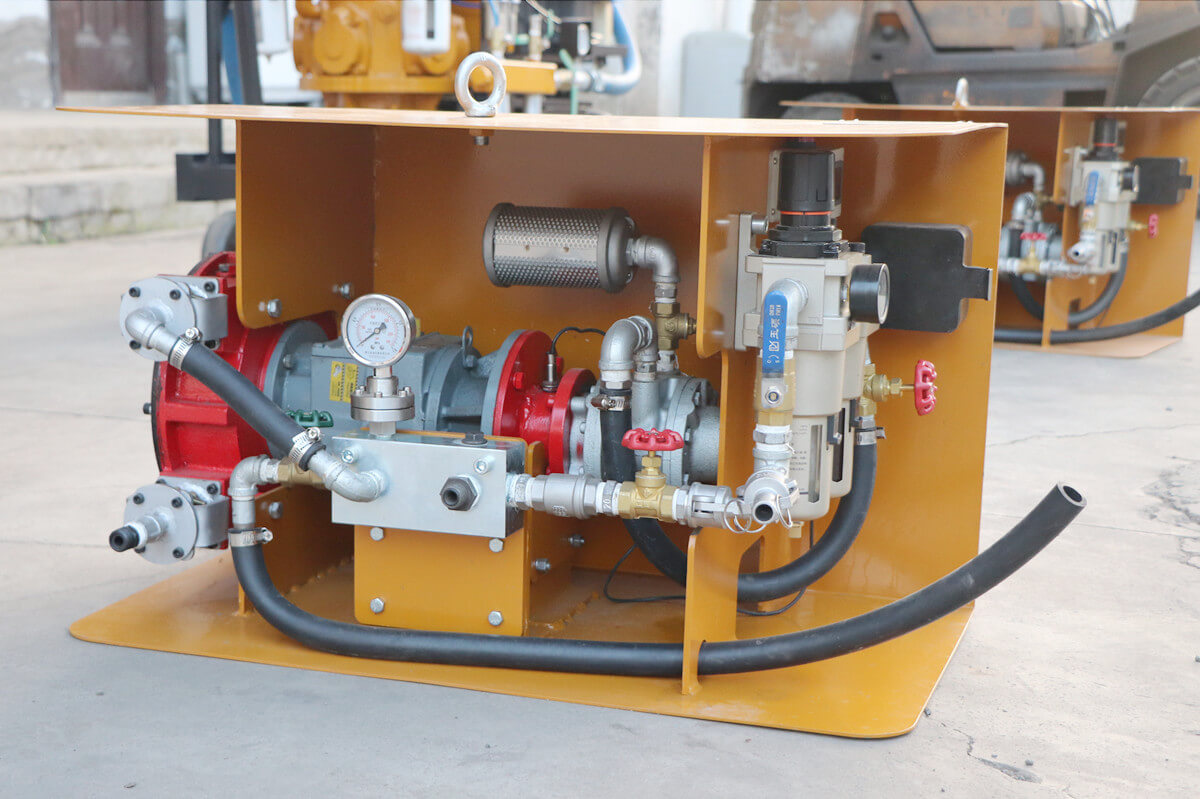

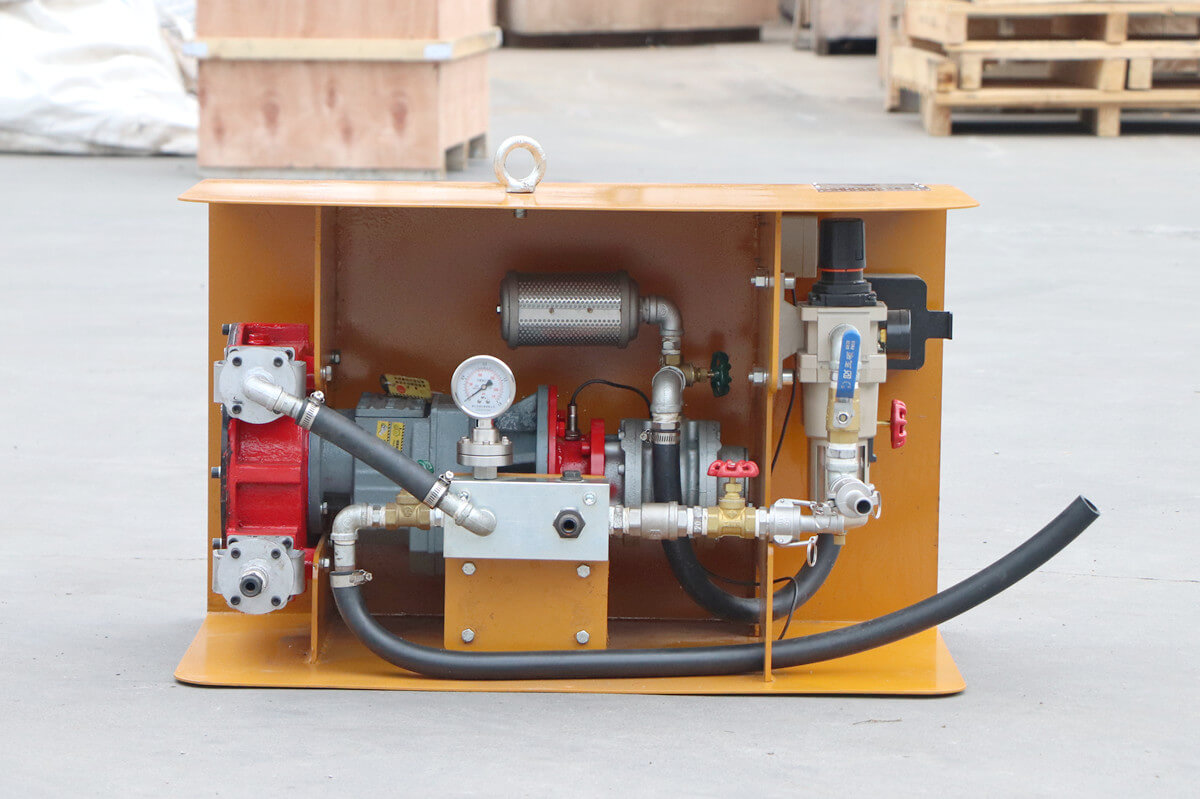

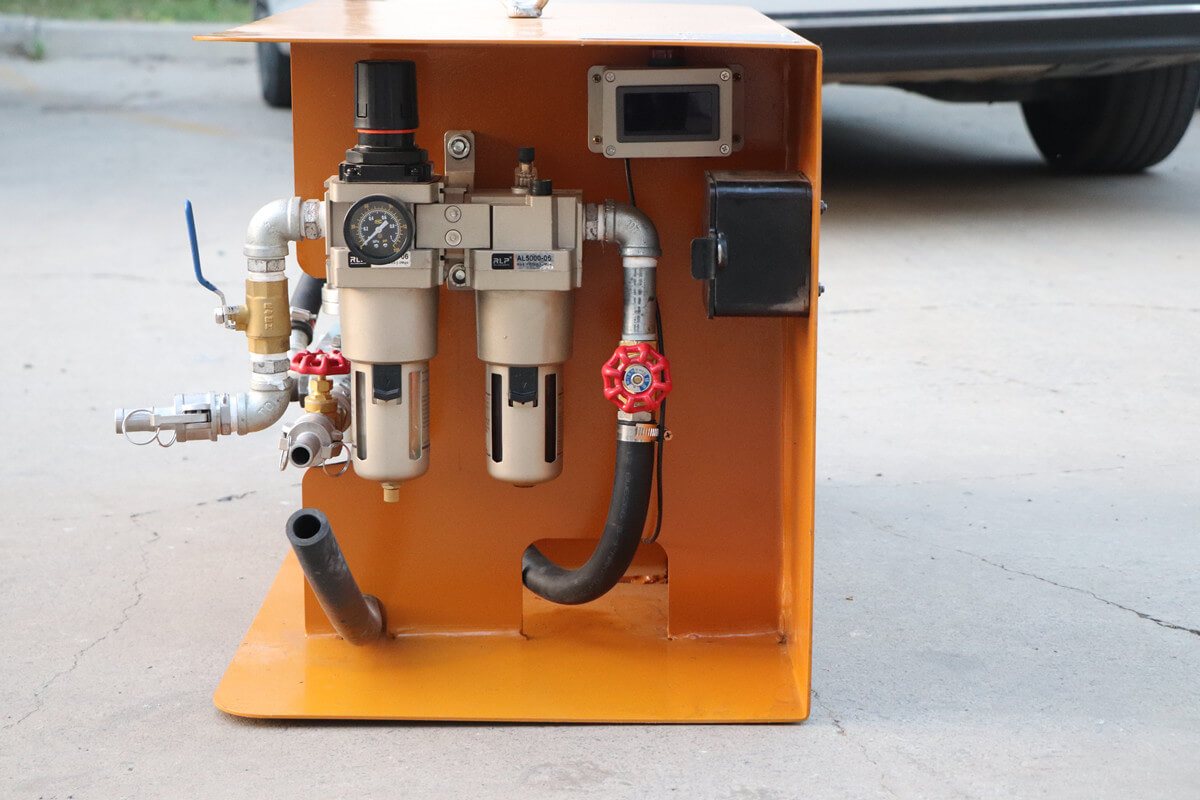

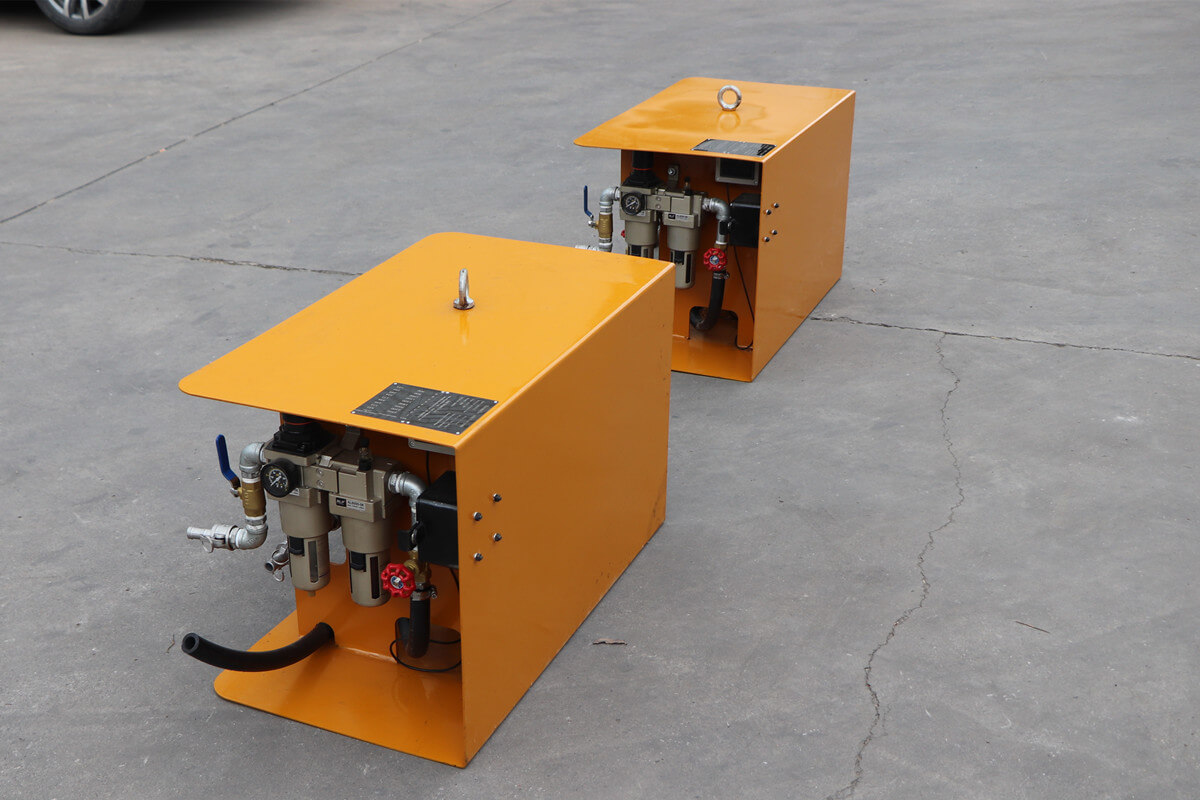

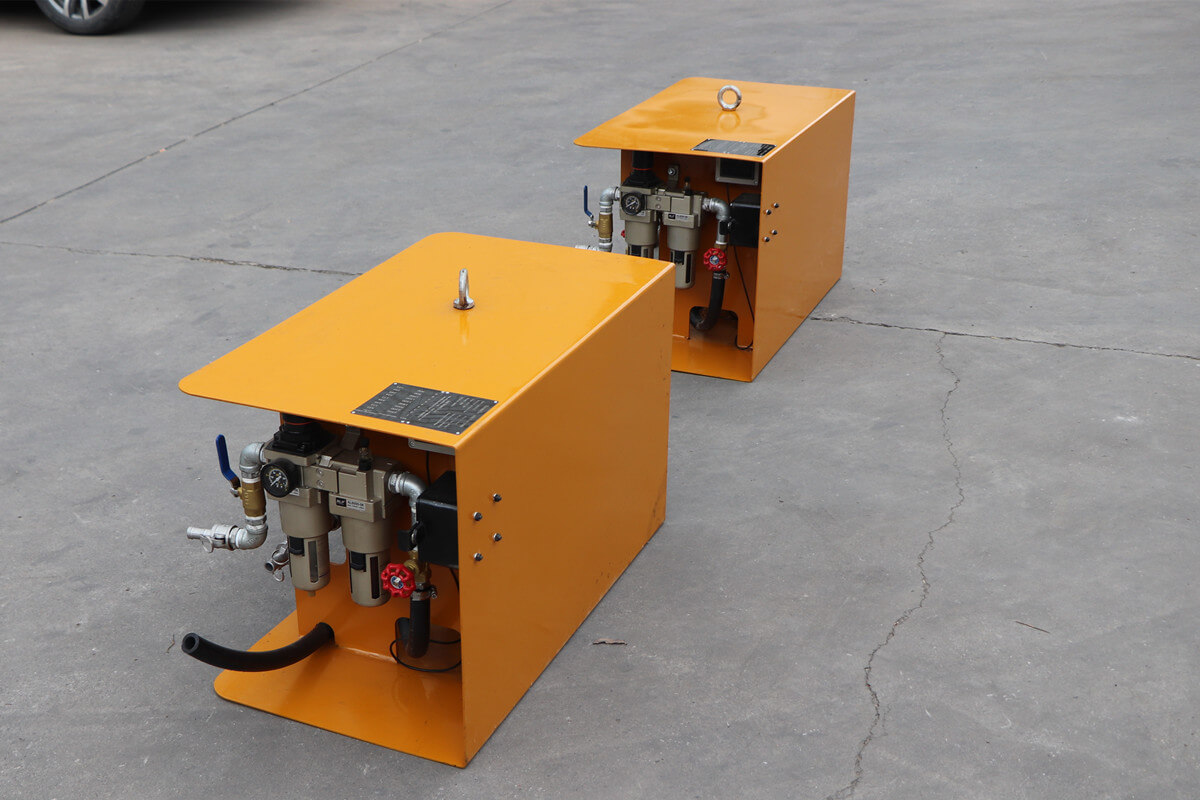

LDUH15A-A Dosing units for shotcrete liquid admixtures

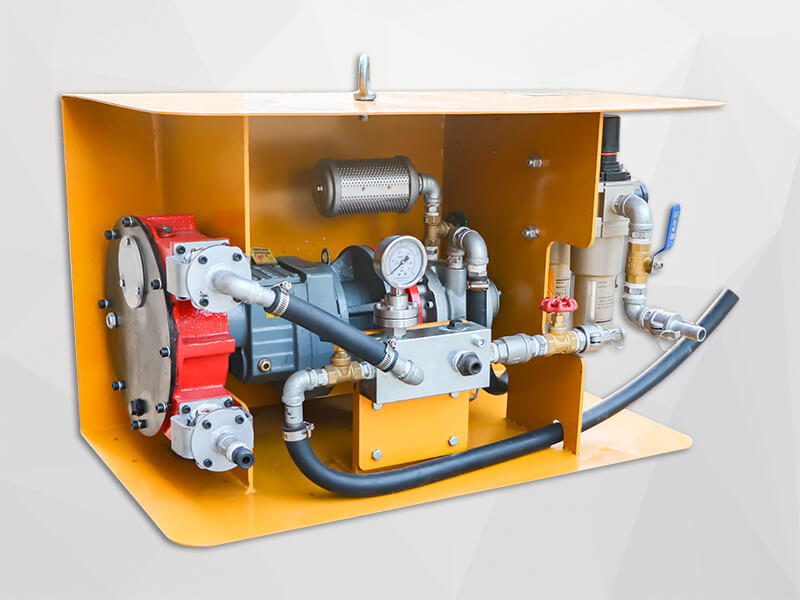

LDUH15A-A Dosing units for shotcrete liquid admixtures can automatically adjust the amount of additives according to the real-time needs of concrete, further improving construction efficiency and concrete quality.

LDUH15A-A

100-600 L/h

4 KW

16 mm

7 bar

3 m³/min

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

LDUH15A-A Dosing units for shotcrete liquid admixtures is a compact, efficient, and easy-to-use machine for liquid admixture dosing in shotcrete applications. Its air-powered design enhances safety and reliability, while the high-quality materials ensure long-lasting performance. With its ability to withstand dry running and offer precise control over additive dosing, it is an excellent tool for ensuring high-quality concrete in a wide range of construction and engineering projects.

Work principle of LDUH15A-A Dosing units for shotcrete liquid admixtures:

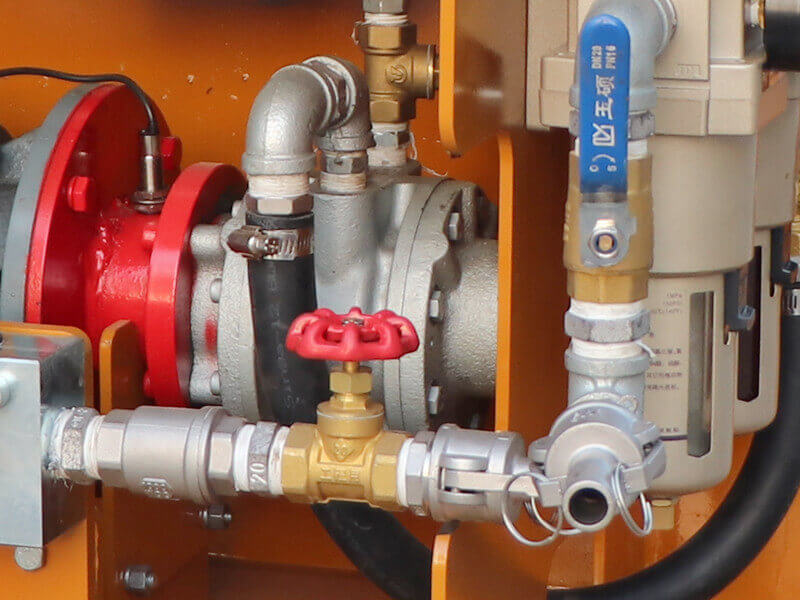

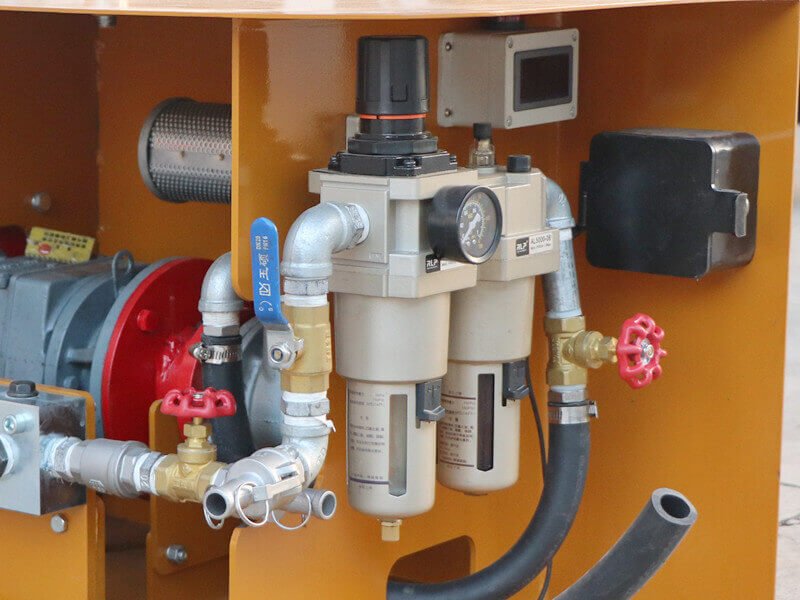

Accurate dosing of liquid admixtures becomes very easy with this device. Connect the water and air hose to the valves, place the suction lance into the additive tank, start the pump and adjust the required dosing with the air valve.

Work principle of LDUH15A-A Dosing units for shotcrete liquid admixtures:

Accurate dosing of liquid admixtures becomes very easy with this device. Connect the water and air hose to the valves, place the suction lance into the additive tank, start the pump and adjust the required dosing with the air valve.

Application

The precise dosing unit for shotcrete and sprayed concrete is particularly suited for several applications within the construction and civil engineering sectors.

1. Tunneling

- **Use Case**: In tunneling projects, shotcrete is commonly used to provide structural support to newly excavated tunnel walls.

- **Application**: This dosing unit, with its precise control and ability to handle both dry and wet spraying, ensures consistent shotcrete application for reinforcing tunnel walls. The minimal rebound and dry-run resistance are crucial in underground environments where access and material conservation are vital.

- **Benefits**: The ease of operation and mobility are essential for tunnels, where equipment needs to be relocated frequently. The pressure gauges help monitor application consistency in difficult conditions.

2. **Slope Stabilization

- **Use Case**: Shotcrete is applied on slopes to prevent erosion, landslides, or rockfalls, particularly in areas near highways or mountainous regions.

- **Application**: The dosing unit provides a stable and controlled shotcrete application, ensuring proper adhesion to uneven or steep surfaces. Its ability to handle dry and wet spraying is useful depending on the specific site conditions.

- **Benefits**: Lightweight and easy to move, the unit can be used on difficult terrain. Precise dosing of additives ensures the right balance of strength and flexibility for slope stabilization.

3. Mining

- **Use Case**: In mining operations, shotcrete is widely used to support underground structures, ensuring the safety of workers and equipment.

- **Application**: The unit allows miners to quickly apply shotcrete to newly excavated areas, ensuring the structural integrity of shafts, tunnels, and chambers.

- **Benefits**: The lightweight, portable design and ability to operate in dry conditions are ideal for underground mining. The air motor's durability and dry-run resistance ensure long-term reliability in demanding environments.

4. Repair and Rehabilitation of Structures

- **Use Case**: In repair projects for aging infrastructure such as bridges, dams, or retaining walls, shotcrete is often used to restore damaged concrete surfaces.

- **Application**: The dosing unit ensures that additives are applied accurately to improve the bonding and durability of the repair materials.

- **Benefits**: The ability to move the lightweight unit around the site and its ease of use makes it ideal for repair work, where access might be challenging. Infinite regulation of dosing ensures precise mixing tailored to the specific repair needs.

5. Hydroelectric and Water Retaining Structures

- **Use Case**: Shotcrete is frequently used in the construction and repair of dams, reservoirs, and water channels.

- **Application**: The one-way valve protecting drinking water from contamination makes this dosing unit particularly suitable for use in water-related infrastructure.

- **Benefits**: Precise dosing ensures the quality and durability of concrete in structures that require water-tightness. Its drinking water protection feature is critical for environments where clean water standards are strict.

6. Foundations and Retaining Walls

- **Use Case**: Shotcrete is used in deep foundation works and the construction of retaining walls to prevent soil movement and support structures.

- **Application**: The dosing unit helps in applying shotcrete to difficult-to-reach areas of foundations, ensuring even distribution and strength.

- **Benefits**: The infinite regulation and minimal rebound features improve application control, particularly in confined spaces or complex structural shapes.

7. Seismic Retrofitting

- **Use Case**: Shotcrete is used to reinforce existing buildings and infrastructure to withstand seismic activity.

- **Application**: The precise dosing ensures that the correct mix of additives is used to enhance the flexibility and shock resistance of the retrofitted structure.

- **Benefits**: Lightweight and easy to operate, the unit can be deployed quickly in urban environments where retrofitting is often necessary, reducing downtime and improving project efficiency.

8. Sprayed Concrete Linings for Shafts and Underground Chambers

- **Use Case**: Sprayed concrete is often used as a primary or secondary lining in the construction of vertical shafts or large underground chambers.

- **Application**: The dosing unit provides the necessary additives for wet spraying in large-scale underground works, where structural integrity is crucial.

- **Benefits**: Infinite regulation allows for adjusting the mix in real-time, which is important when dealing with varying ground conditions. Pressure gauges ensure the spray pressure remains within safe and effective limits.

Summary of Benefits for Applications:

- **Precision**: Ensures high-quality shotcrete application in demanding environments.

- **Versatility**: Suitable for both dry and wet shotcrete applications across multiple sectors.

- **Efficiency**: Minimizes waste and rebound, optimizing material use.

- **Mobility**: Lightweight and easy to move, making it ideal for dynamic and challenging construction sites.

- **Safety and Reliability**: Features like dry-run resistance, one-way valve, and visible pressure monitoring improve operational safety and system longevity.

LDUH15A-A Dosing units for shotcrete liquid admixtures enhances efficiency and quality across a wide range of shotcrete applications, providing reliable, consistent performance in various construction and engineering projects.

1. Tunneling

- **Use Case**: In tunneling projects, shotcrete is commonly used to provide structural support to newly excavated tunnel walls.

- **Application**: This dosing unit, with its precise control and ability to handle both dry and wet spraying, ensures consistent shotcrete application for reinforcing tunnel walls. The minimal rebound and dry-run resistance are crucial in underground environments where access and material conservation are vital.

- **Benefits**: The ease of operation and mobility are essential for tunnels, where equipment needs to be relocated frequently. The pressure gauges help monitor application consistency in difficult conditions.

2. **Slope Stabilization

- **Use Case**: Shotcrete is applied on slopes to prevent erosion, landslides, or rockfalls, particularly in areas near highways or mountainous regions.

- **Application**: The dosing unit provides a stable and controlled shotcrete application, ensuring proper adhesion to uneven or steep surfaces. Its ability to handle dry and wet spraying is useful depending on the specific site conditions.

- **Benefits**: Lightweight and easy to move, the unit can be used on difficult terrain. Precise dosing of additives ensures the right balance of strength and flexibility for slope stabilization.

3. Mining

- **Use Case**: In mining operations, shotcrete is widely used to support underground structures, ensuring the safety of workers and equipment.

- **Application**: The unit allows miners to quickly apply shotcrete to newly excavated areas, ensuring the structural integrity of shafts, tunnels, and chambers.

- **Benefits**: The lightweight, portable design and ability to operate in dry conditions are ideal for underground mining. The air motor's durability and dry-run resistance ensure long-term reliability in demanding environments.

4. Repair and Rehabilitation of Structures

- **Use Case**: In repair projects for aging infrastructure such as bridges, dams, or retaining walls, shotcrete is often used to restore damaged concrete surfaces.

- **Application**: The dosing unit ensures that additives are applied accurately to improve the bonding and durability of the repair materials.

- **Benefits**: The ability to move the lightweight unit around the site and its ease of use makes it ideal for repair work, where access might be challenging. Infinite regulation of dosing ensures precise mixing tailored to the specific repair needs.

5. Hydroelectric and Water Retaining Structures

- **Use Case**: Shotcrete is frequently used in the construction and repair of dams, reservoirs, and water channels.

- **Application**: The one-way valve protecting drinking water from contamination makes this dosing unit particularly suitable for use in water-related infrastructure.

- **Benefits**: Precise dosing ensures the quality and durability of concrete in structures that require water-tightness. Its drinking water protection feature is critical for environments where clean water standards are strict.

6. Foundations and Retaining Walls

- **Use Case**: Shotcrete is used in deep foundation works and the construction of retaining walls to prevent soil movement and support structures.

- **Application**: The dosing unit helps in applying shotcrete to difficult-to-reach areas of foundations, ensuring even distribution and strength.

- **Benefits**: The infinite regulation and minimal rebound features improve application control, particularly in confined spaces or complex structural shapes.

7. Seismic Retrofitting

- **Use Case**: Shotcrete is used to reinforce existing buildings and infrastructure to withstand seismic activity.

- **Application**: The precise dosing ensures that the correct mix of additives is used to enhance the flexibility and shock resistance of the retrofitted structure.

- **Benefits**: Lightweight and easy to operate, the unit can be deployed quickly in urban environments where retrofitting is often necessary, reducing downtime and improving project efficiency.

8. Sprayed Concrete Linings for Shafts and Underground Chambers

- **Use Case**: Sprayed concrete is often used as a primary or secondary lining in the construction of vertical shafts or large underground chambers.

- **Application**: The dosing unit provides the necessary additives for wet spraying in large-scale underground works, where structural integrity is crucial.

- **Benefits**: Infinite regulation allows for adjusting the mix in real-time, which is important when dealing with varying ground conditions. Pressure gauges ensure the spray pressure remains within safe and effective limits.

Summary of Benefits for Applications:

- **Precision**: Ensures high-quality shotcrete application in demanding environments.

- **Versatility**: Suitable for both dry and wet shotcrete applications across multiple sectors.

- **Efficiency**: Minimizes waste and rebound, optimizing material use.

- **Mobility**: Lightweight and easy to move, making it ideal for dynamic and challenging construction sites.

- **Safety and Reliability**: Features like dry-run resistance, one-way valve, and visible pressure monitoring improve operational safety and system longevity.

LDUH15A-A Dosing units for shotcrete liquid admixtures enhances efficiency and quality across a wide range of shotcrete applications, providing reliable, consistent performance in various construction and engineering projects.

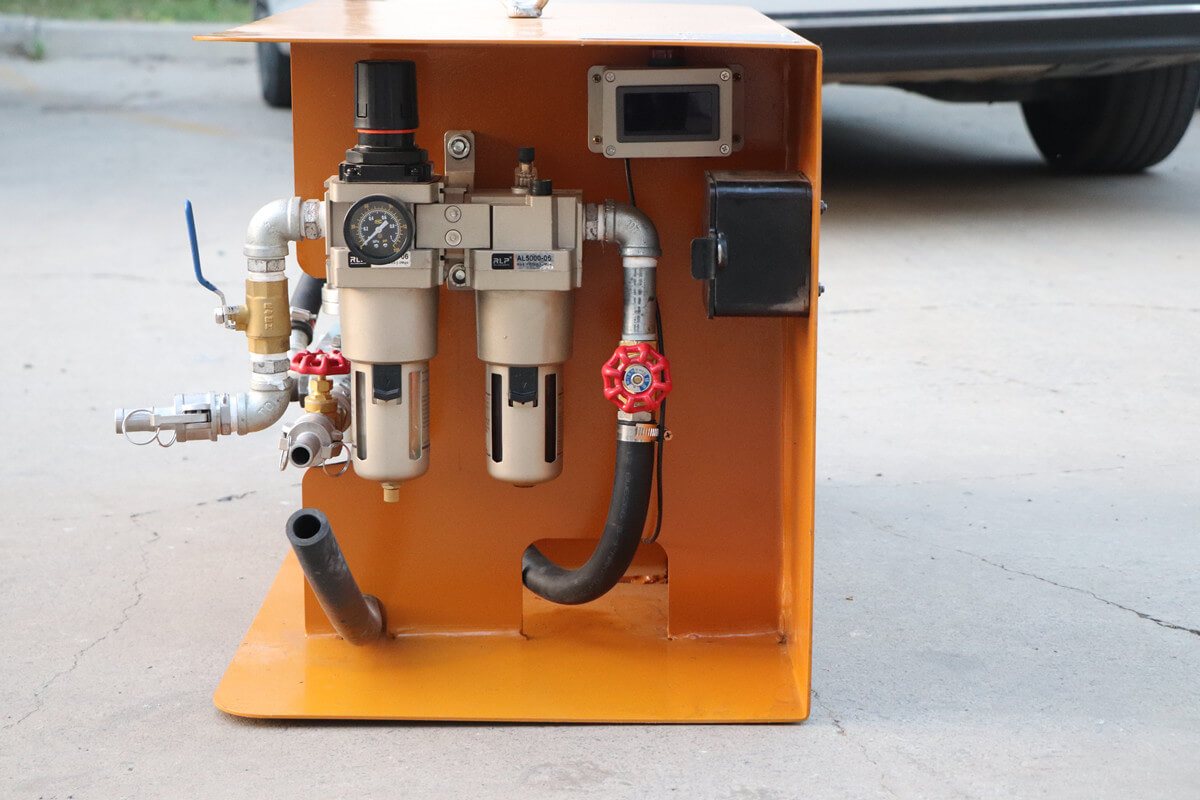

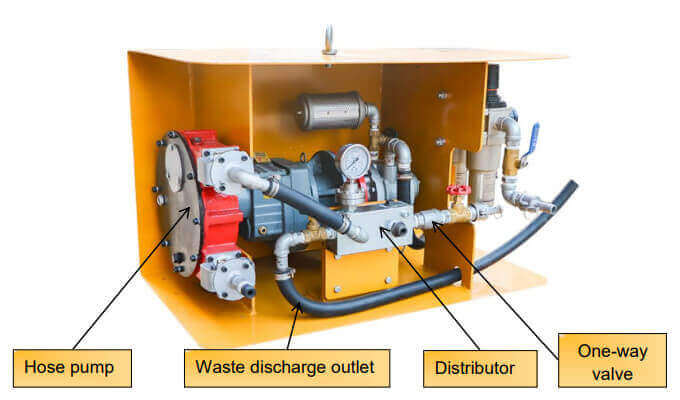

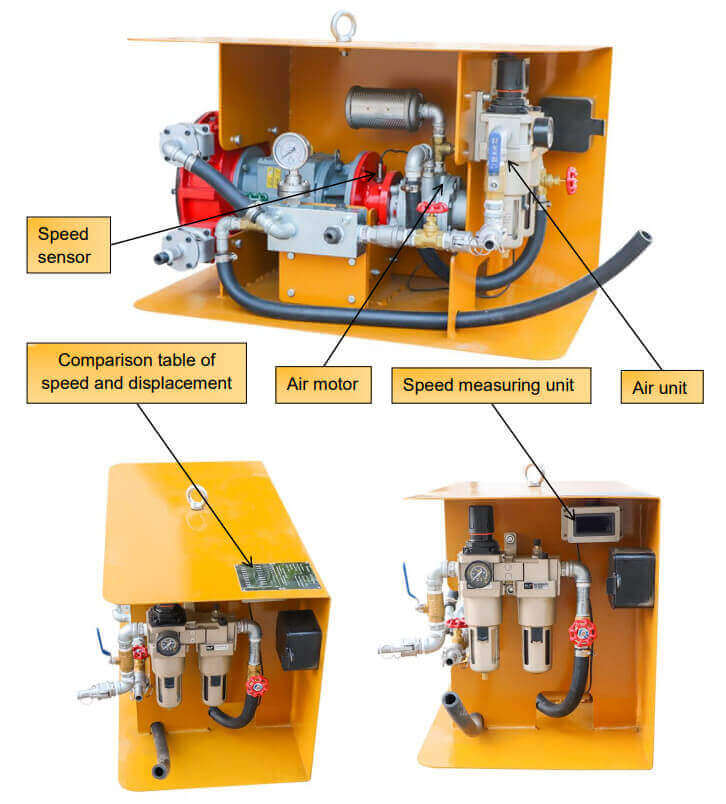

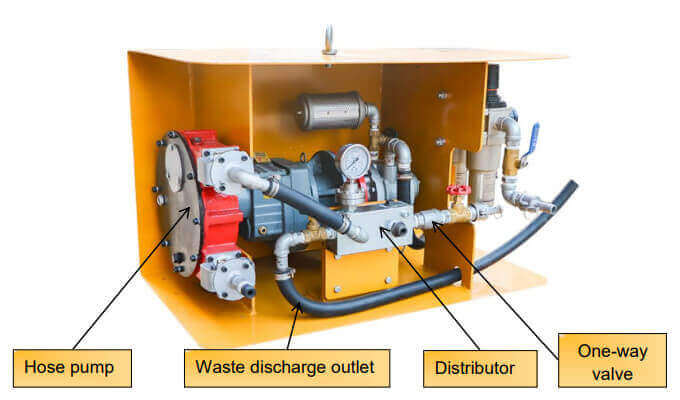

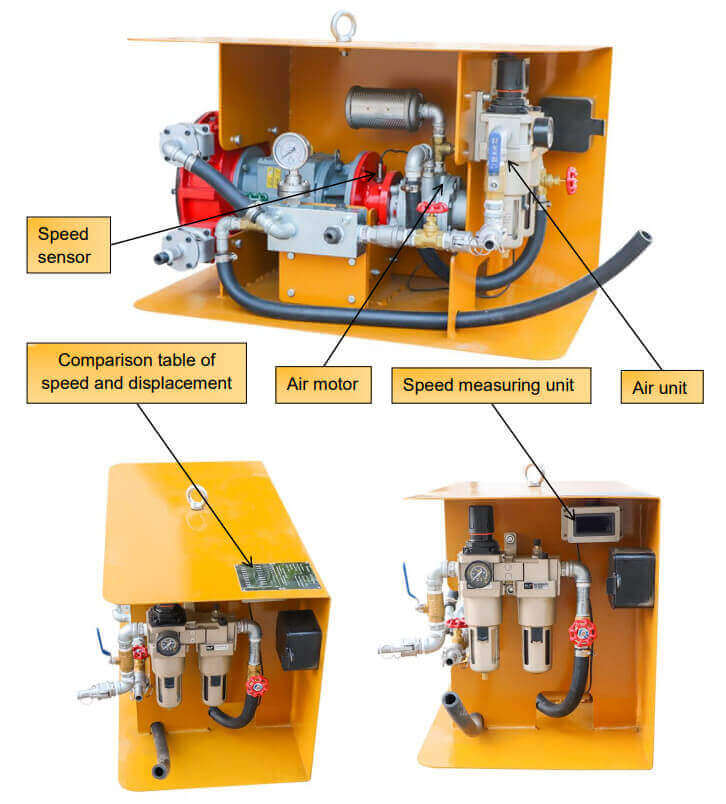

Features

A precise dosing unit for shotcrete applications is designed for both dry and wet spraying.

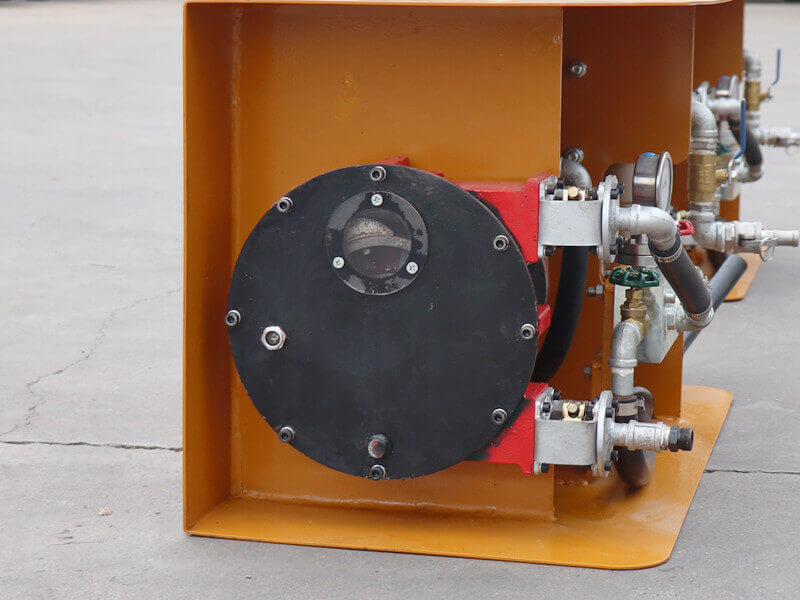

1. Direct Drive 4kW Air Motor

- Function: The air motor directly powers the dosing unit without the need for intermediate mechanisms like gears or belts. This results in more efficient power transmission and fewer moving parts, which reduces wear and maintenance.

- Benefit: Increased reliability and efficiency, especially in harsh construction environments where electric or hydraulic motors might be less effective.

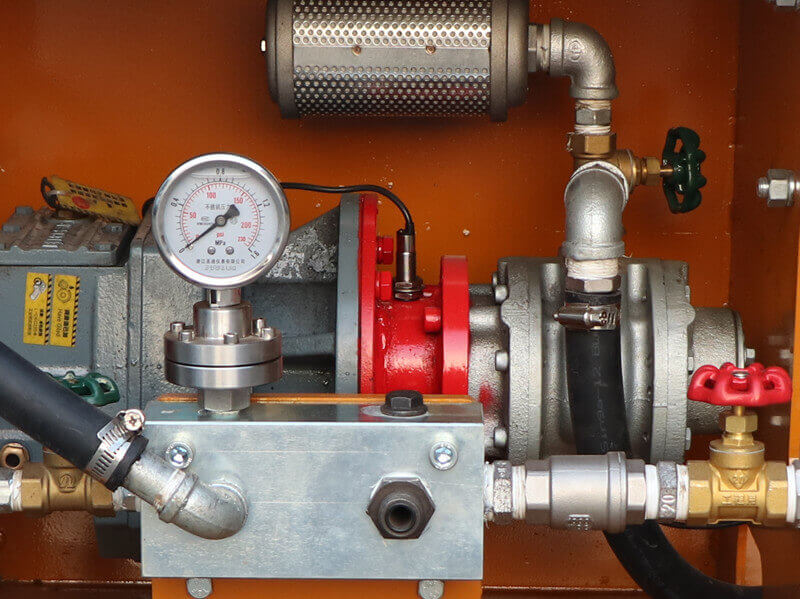

2. Precise Dosing

- Function: The unit offers highly accurate dosing of additives, ensuring that the right amount is mixed into the shotcrete. This is crucial for maintaining the correct mix quality, particularly with accelerators, retarders, or plasticizers.

- Benefit: Improves the consistency of the shotcrete, leading to better bonding, strength, and durability.

3. For Dry and Wet Spraying

- Function: The dosing unit is versatile, capable of being used for both dry-mix (shotcrete) and wet-mix (sprayed concrete) applications.

- Benefit: One system can handle multiple applications, providing flexibility on-site and reducing the need for different equipment for different spraying methods.

4. Little Rebound

- Function: The design minimizes the amount of rebound, which is the material that bounces off the surface during spraying.

- Benefit: Less waste material, improved cost-efficiency, and a cleaner work environment.

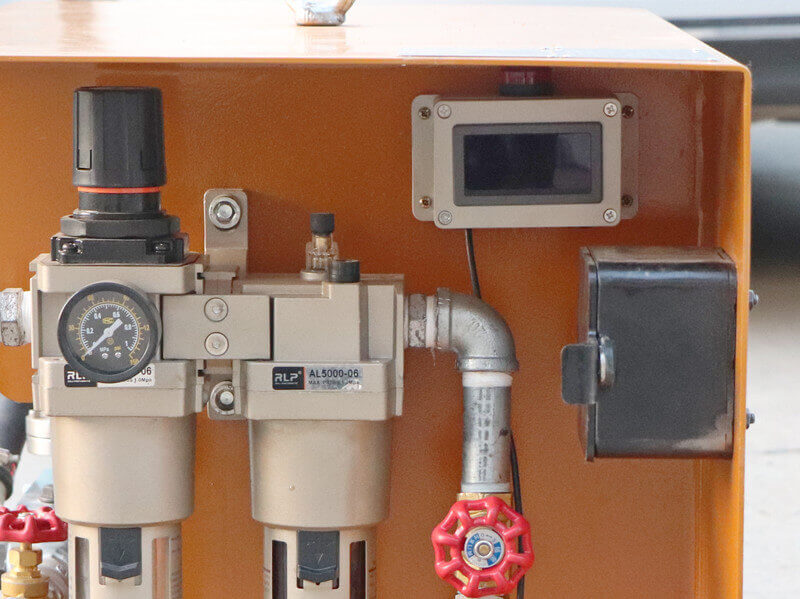

5. Infinite Regulation

- Function: The dosing unit offers continuous, adjustable control over the amount of additive being dispensed, rather than fixed increments.

- Benefit: Greater flexibility to fine-tune the mixture on the fly, adapting to changing conditions or requirements on the job site.

6. Dry Run Resistant

- Function: The unit is capable of running without liquid or material for a period of time without damage.

- Benefit: Reduced risk of damage if the additive supply runs out unexpectedly, leading to fewer breakdowns and maintenance issues.

7. Pressure Gauges, Pressure Visible

- Function: Pressure gauges provide a clear, real-time indication of system pressure.

- Benefit: Operators can monitor the system easily to ensure proper dosing and identify any potential issues like clogs or leaks.

8. One-Way Valve, for Drinking Water Protection

- Function: A one-way (non-return) valve prevents backflow, ensuring that additives or other substances do not contaminate the water supply.

- Benefit: Critical in applications where safety and hygiene standards are strict, particularly when potable water is involved.

9. Easy to Operate and Maintain

- Function: The design is straightforward, making it easy for operators to control the dosing unit and perform routine maintenance.

- Benefit: Reduces training requirements, operator errors, and downtime for repairs, enhancing overall productivity.

10. Lightweight and Easy to Move

- Function: The unit is designed to be portable, making it easy to transport and position in different locations on the job site.

- Benefit: Ideal for projects where mobility is essential, such as tunneling or large-scale concrete repair work, where equipment must be relocated frequently.

This dosing unit, with its powerful 4kW air motor, precision, and versatility for both dry and wet spraying, is engineered to improve efficiency and adaptability in shotcrete applications. The features like dry-run resistance, infinite regulation, and lightweight design make it an ideal solution for modern construction needs. Its safety features, including the one-way valve for water protection, also make it suitable for projects where environmental standards are critical.

1. Direct Drive 4kW Air Motor

- Function: The air motor directly powers the dosing unit without the need for intermediate mechanisms like gears or belts. This results in more efficient power transmission and fewer moving parts, which reduces wear and maintenance.

- Benefit: Increased reliability and efficiency, especially in harsh construction environments where electric or hydraulic motors might be less effective.

2. Precise Dosing

- Function: The unit offers highly accurate dosing of additives, ensuring that the right amount is mixed into the shotcrete. This is crucial for maintaining the correct mix quality, particularly with accelerators, retarders, or plasticizers.

- Benefit: Improves the consistency of the shotcrete, leading to better bonding, strength, and durability.

3. For Dry and Wet Spraying

- Function: The dosing unit is versatile, capable of being used for both dry-mix (shotcrete) and wet-mix (sprayed concrete) applications.

- Benefit: One system can handle multiple applications, providing flexibility on-site and reducing the need for different equipment for different spraying methods.

4. Little Rebound

- Function: The design minimizes the amount of rebound, which is the material that bounces off the surface during spraying.

- Benefit: Less waste material, improved cost-efficiency, and a cleaner work environment.

5. Infinite Regulation

- Function: The dosing unit offers continuous, adjustable control over the amount of additive being dispensed, rather than fixed increments.

- Benefit: Greater flexibility to fine-tune the mixture on the fly, adapting to changing conditions or requirements on the job site.

6. Dry Run Resistant

- Function: The unit is capable of running without liquid or material for a period of time without damage.

- Benefit: Reduced risk of damage if the additive supply runs out unexpectedly, leading to fewer breakdowns and maintenance issues.

7. Pressure Gauges, Pressure Visible

- Function: Pressure gauges provide a clear, real-time indication of system pressure.

- Benefit: Operators can monitor the system easily to ensure proper dosing and identify any potential issues like clogs or leaks.

8. One-Way Valve, for Drinking Water Protection

- Function: A one-way (non-return) valve prevents backflow, ensuring that additives or other substances do not contaminate the water supply.

- Benefit: Critical in applications where safety and hygiene standards are strict, particularly when potable water is involved.

9. Easy to Operate and Maintain

- Function: The design is straightforward, making it easy for operators to control the dosing unit and perform routine maintenance.

- Benefit: Reduces training requirements, operator errors, and downtime for repairs, enhancing overall productivity.

10. Lightweight and Easy to Move

- Function: The unit is designed to be portable, making it easy to transport and position in different locations on the job site.

- Benefit: Ideal for projects where mobility is essential, such as tunneling or large-scale concrete repair work, where equipment must be relocated frequently.

This dosing unit, with its powerful 4kW air motor, precision, and versatility for both dry and wet spraying, is engineered to improve efficiency and adaptability in shotcrete applications. The features like dry-run resistance, infinite regulation, and lightweight design make it an ideal solution for modern construction needs. Its safety features, including the one-way valve for water protection, also make it suitable for projects where environmental standards are critical.

Product Details

Technical Parameters

Technical Data

| Model | LDUH15A-A Dosing units for shotcrete liquid admixtures |

| Pumping output | 100-600 L/h |

| Air motor power | 4 KW |

| Hose ID | 16 mm |

| Air pressure | 7 bar |

| Air consumption | 3 m³/min |

| Air/Water connection | Quick coupler 3/4” |

| Conveying water pressure | Min. 4 bar Max. 8.5 bar |

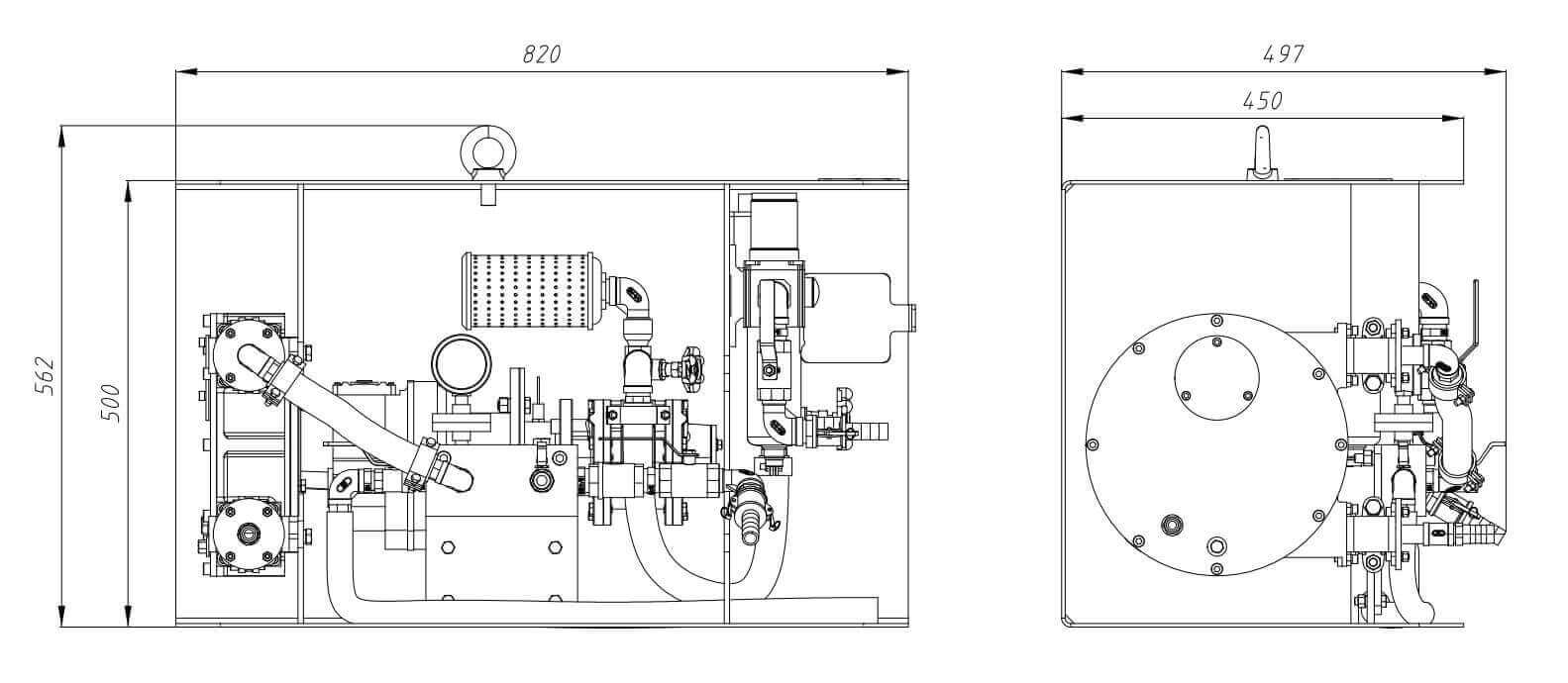

| Dimension | 820×497×500 mm |

| Weight | 160 Kg |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LSZ-10S/E dry and wet mix shotcrete machine is a multifunctional rotor type machine for wet and dry spraying and conveying concrete with an electric motor.LSZ-10S/E Electric motor dry and wet shotcrete machine

LSZ-10S/E dry and wet mix shotcrete machine is a multifunctional rotor type machine for wet and dry spraying and conveying concrete with an electric motor.LSZ-10S/E Electric motor dry and wet shotcrete machine -

LSZ-10S Dry wet type concrete spraying machine for sale made in China has a series of models, a variety of choices, according to specific requirements, can be flexibly selected, saving more money for your project!LSZ-10S Dry wet type concrete spraying machine

LSZ-10S Dry wet type concrete spraying machine for sale made in China has a series of models, a variety of choices, according to specific requirements, can be flexibly selected, saving more money for your project!LSZ-10S Dry wet type concrete spraying machine -

LZ-3A Air motor dry mix concrete spraying machine is widely used in engineering and construction, mining, tunnel, culvert, subway, hydropower engineering, underground engineering and high marsh coal mine tunnel shotcrete construction operations.LZ-3A Air motor dry mix concrete spraying machine

LZ-3A Air motor dry mix concrete spraying machine is widely used in engineering and construction, mining, tunnel, culvert, subway, hydropower engineering, underground engineering and high marsh coal mine tunnel shotcrete construction operations.LZ-3A Air motor dry mix concrete spraying machine -

Leadcrete Shotcrete Pump has the advantage of high quality and competitive price and good after-sales service.LDS2000E Shotcrete Pump

Leadcrete Shotcrete Pump has the advantage of high quality and competitive price and good after-sales service.LDS2000E Shotcrete Pump

.jpg)

.jpg)