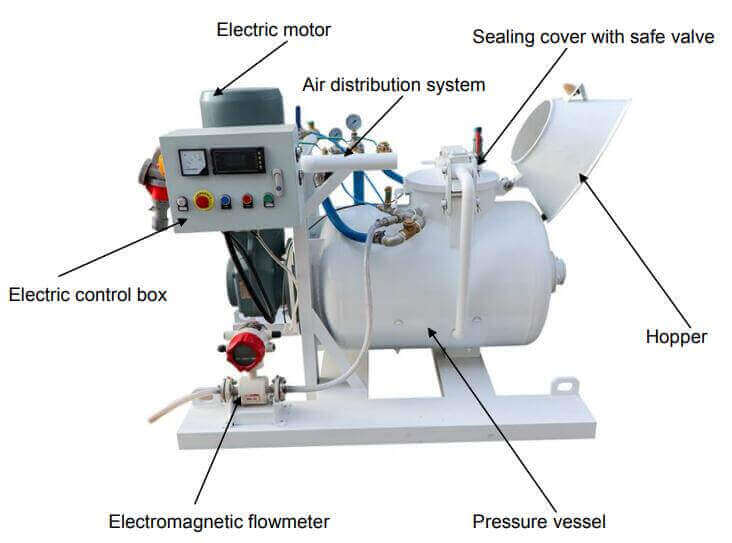

Working principle of LDPX Pneumatic refractory mixing and pressure conveying unit:

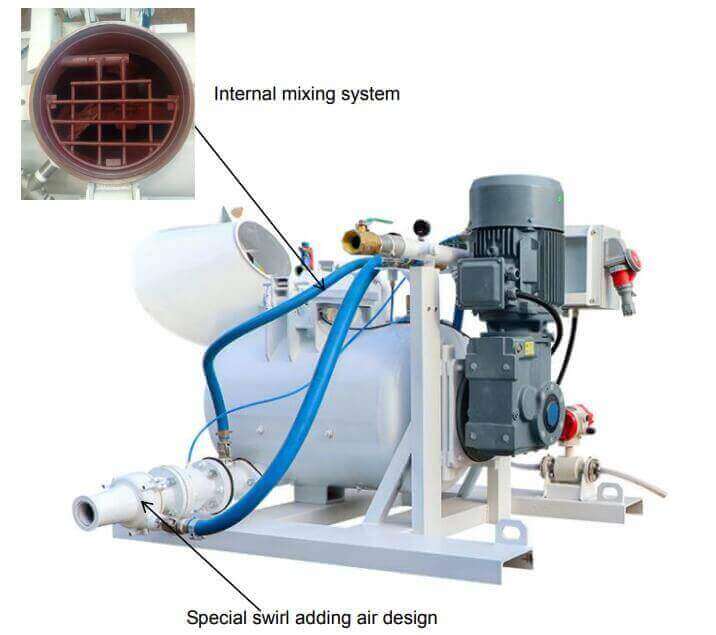

Mixture closed in the pressure tank will be mixed by motion of mixing blades and by the compressed air. Mixing blades slide simultaneously the mixture and push it into the discharge port of the tank. Additional, lower position compressed air entering into the conveying hose and blow mixture uniform motion of in transport hoses. Transport of the mixture in the conveying hose passes in agglomerates, and unique swirling air path design makes the materials will not produce large fluctuations.

The LDPX Pneumatic Refractory Mixing and Pressure Conveying Unit is a highly efficient and versatile system, essential for various industrial applications. Its ability to handle both concrete and refractory materials makes it an invaluable asset in metallurgy and civil engineering, providing consistent quality, durability, and safety in high-temperature and large-scale construction projects.

-

Manufacture and Transport of Solid and Damp Concrete Mixture and Refractory Materials:

- The unit is capable of handling various concrete mixtures, ensuring they are thoroughly mixed and pneumatically conveyed to the application site.

- Refractory materials, which are essential for high-temperature applications, are mixed and transported efficiently, maintaining their integrity and consistency.

-

Metallurgical Applications:

- Pig Iron Production: The unit is used for spout and gutter concreting, ensuring durable and heat-resistant linings in pig iron production facilities.

- Steel Production: It facilitates the concreting of steel ladles and lids, providing robust and high-temperature resistant linings necessary for handling molten steel.

-

Civil Engineering Applications:

- Structure Foundation Floor: The unit can pump concrete for large foundation floors, ensuring a uniform and robust base for various structures.

- Large Concrete Area Pumping: Ideal for large-scale concrete projects, the unit can efficiently pump concrete to extensive areas, ensuring consistent application and quality.

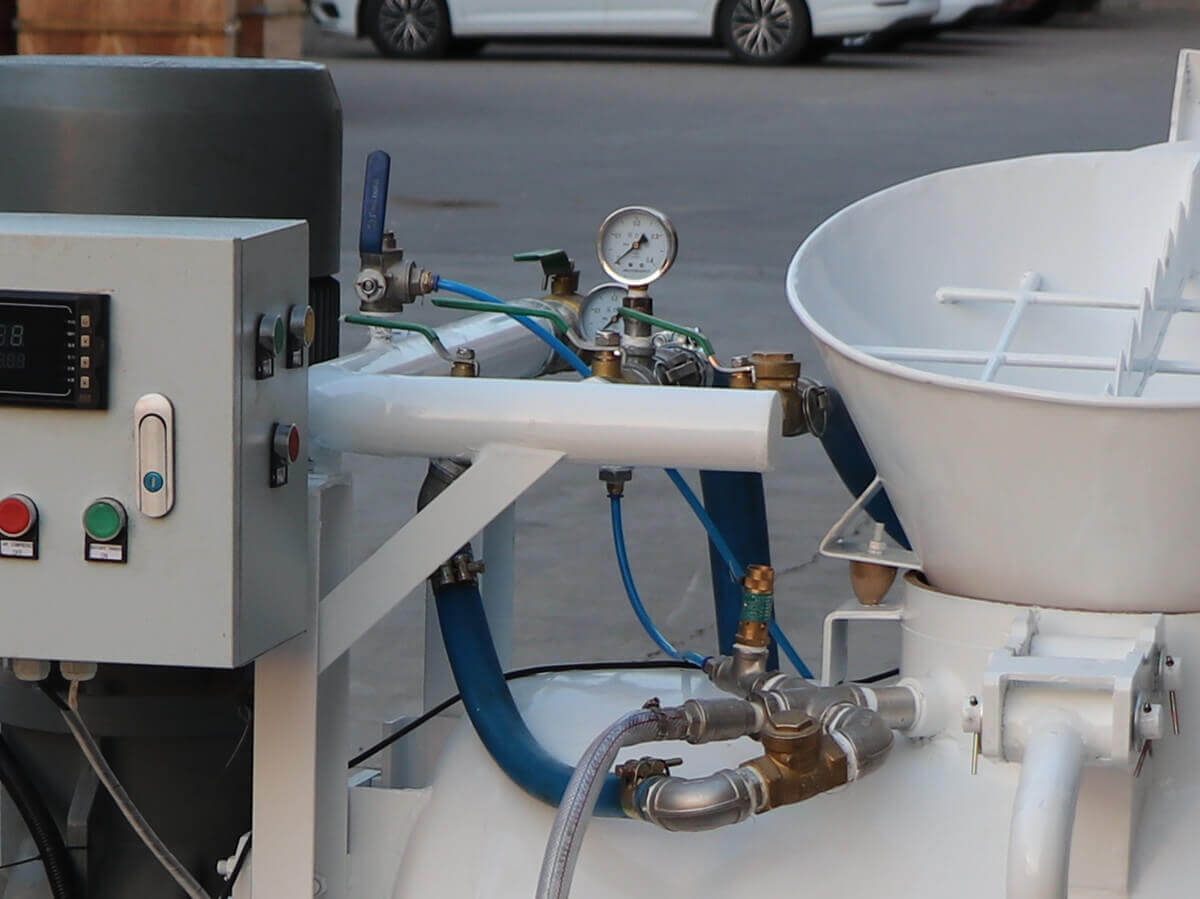

★ Exact electronically water dosage system;

★ Mixture of consistently homogenous mixing quality;

★ Easy to handle system regarding installation, conveying and cleansing;

★ Saving of man power and cost;

★ Conveying of materials which are difficult to pump.

These features make the LDPX Pneumatic Refractory Mixing and Pressure Conveying Unit a valuable asset for industries requiring efficient, reliable, and high-quality mixing and conveying of refractory and concrete materials.

| Model | LDPX200 | LDPX500 | LDPX600 |

| Output Capacity | 4m3/h | 10m3/h | 10m3/h |

| Useful vessel volume | 200L | 500L | 600L |

| Total vessel volume | 250L | 660L | 800L |

| Max. Grain size of mixture | 16mm | 32mm | 32mm |

| Electric motor power | 11Kw | 22Kw | 30Kw |

| Conveying distance | Horizontal 100m, Vertical 40m | ||

| Operating pressure | 0.2~0.4Mpa | 0.2~0.4Mpa | 0.2~0.4Mpa |

| Max. vessel pressure | 0.8Mpa | 0.8Mpa | 0.8Mpa |

| Required compressed air | 4~6m3/min | 5~10m3/min | 5~10m3/min |

| Dimension | 1.55x1.55x1.25m | 2.88x1.4x1.85m | 3.32x1.4x1.85m |

| Weight | 668Kg | 1640Kg | 1740Kg |

-

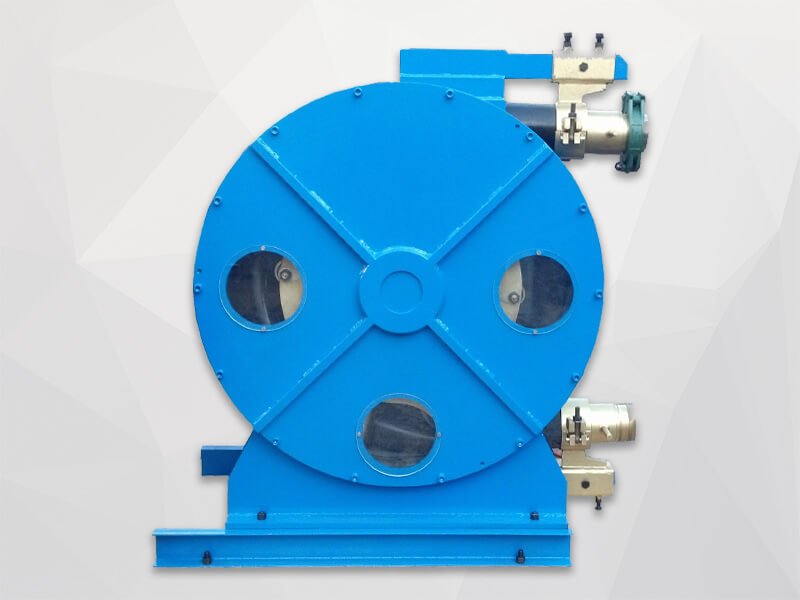

Refractory gunning machine is a stereotyped product with good quality and durability. The wearing parts, rotating plate, bonding plate, spray gun and other accessories are adequately stocked.LZ-3ER/S Refractory gunning machine

Refractory gunning machine is a stereotyped product with good quality and durability. The wearing parts, rotating plate, bonding plate, spray gun and other accessories are adequately stocked.LZ-3ER/S Refractory gunning machine -

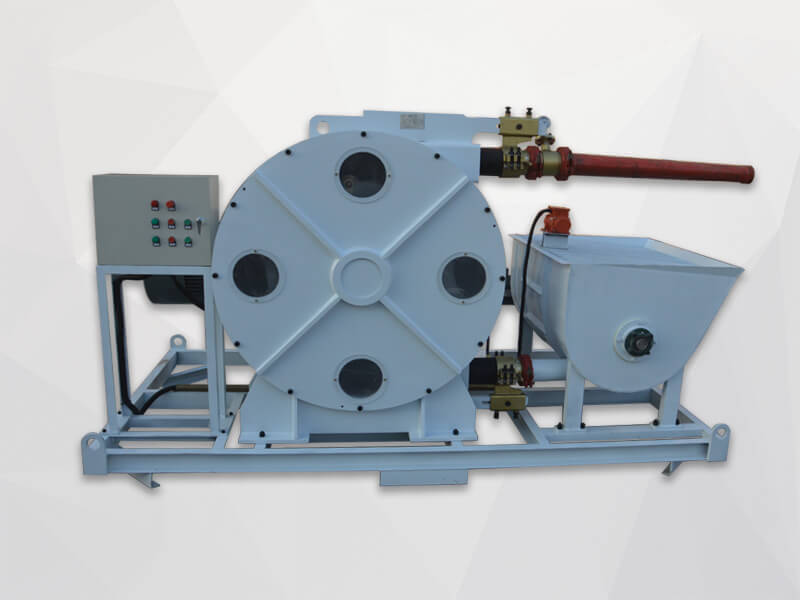

LZ-5AR refractory spraying machine is driven by one air motor (also it could be driven by a electrical motor). LZ-5AR is a powerful, compact and reliable refractory material spraying machine, it is specifically designed for refractory dry mix shotcrete application, as well as for concrete shotcrete application.LZ-5AR Refractory spraying machine

LZ-5AR refractory spraying machine is driven by one air motor (also it could be driven by a electrical motor). LZ-5AR is a powerful, compact and reliable refractory material spraying machine, it is specifically designed for refractory dry mix shotcrete application, as well as for concrete shotcrete application.LZ-5AR Refractory spraying machine -

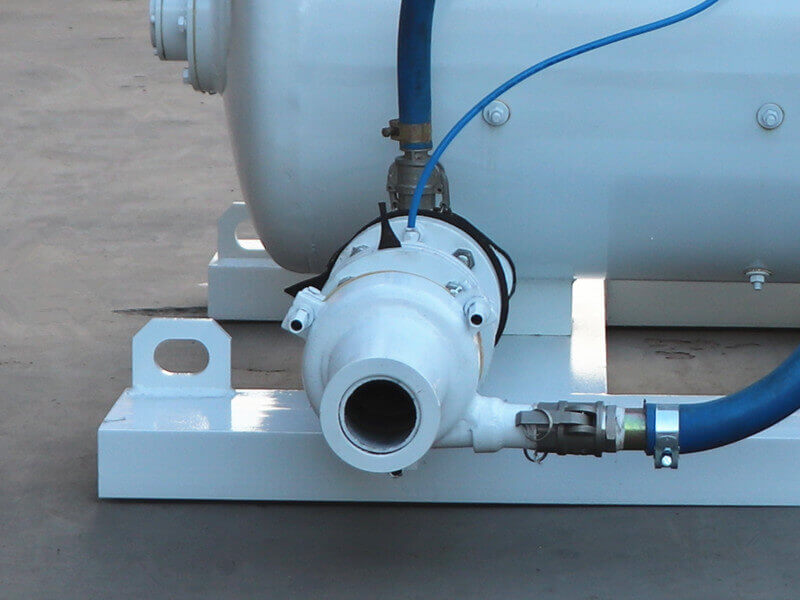

LZ-3ER refractory gunite machine is a dry monolithic refractory material designed for dry spray gun equipment. The spray gun is applied by a special machine that uses compressed air to push the dry (or pre-wetted) spray gun through the hose into the target. Add water (or additives) to the nozzle to wet the dry mixture and make it stick to the surface.LZ-3ER Refractory Gunite Machine Price

LZ-3ER refractory gunite machine is a dry monolithic refractory material designed for dry spray gun equipment. The spray gun is applied by a special machine that uses compressed air to push the dry (or pre-wetted) spray gun through the hose into the target. Add water (or additives) to the nozzle to wet the dry mixture and make it stick to the surface.LZ-3ER Refractory Gunite Machine Price -

LZ-5ER gunning machine for refractory for sale is a dry gunning machine designed for dry spraying refractory materials. It usually contains additives that make it more sticky.LZ-5ER Gunning Machine for Refractory

LZ-5ER gunning machine for refractory for sale is a dry gunning machine designed for dry spraying refractory materials. It usually contains additives that make it more sticky.LZ-5ER Gunning Machine for Refractory

.jpg)

.jpg)