Your position:

Home > Products > Grout Pump

LGP440/50PI-22E High pressure grout injection pump for drilling rig

High pressure grout injection pump for drilling rig is crucial in various construction and geotechnical applications, such as stabilizing soil, filling voids, or strengthening foundations.

Horizontal three-cylinder reciprocating single-action piston pump

100

110

22

214

440

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

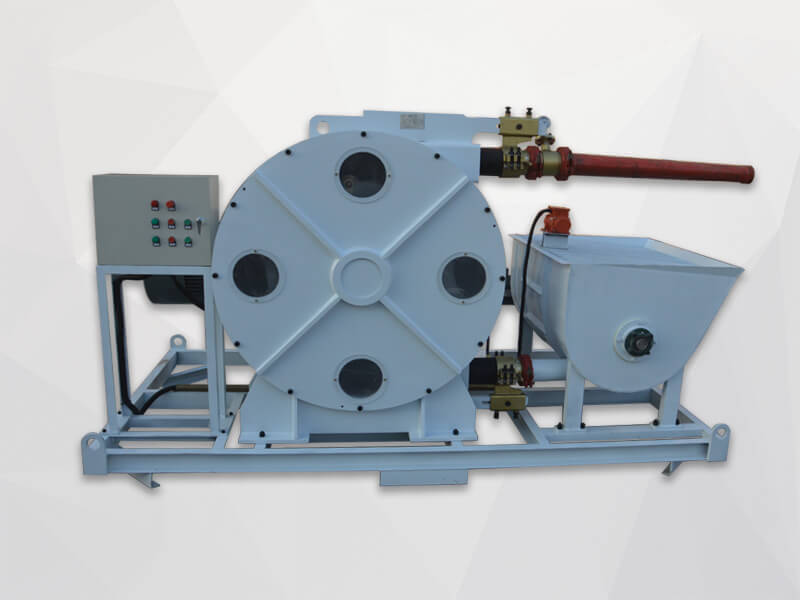

LGP440/50PI-22E High pressure grout injection pump for drilling rig is one of the commonly used equipment in drilling and geological exploration. It is mainly used to inject high-pressure grout into the borehole to reinforce the stratum, stop water or perform other geological engineering treatments.

LGP440/50PI-22E High pressure grout injection pump has a mature and reliable frequency converter, with the characteristics of safety, energy saving, convenient operation and maintenance. At the same time, the advanced artificial intelligence control is adopted, which is used to realize the display and control of pressure, with the function of instantaneous flow display and accumulation. In addition, the use of crankcase and gearbox integrated design, so the pump is not only reliable performance, long service life, but also small volume and light quality, good decomposition, easy to move.

LGP440/50PI-22E High pressure grout injection pump has a mature and reliable frequency converter, with the characteristics of safety, energy saving, convenient operation and maintenance. At the same time, the advanced artificial intelligence control is adopted, which is used to realize the display and control of pressure, with the function of instantaneous flow display and accumulation. In addition, the use of crankcase and gearbox integrated design, so the pump is not only reliable performance, long service life, but also small volume and light quality, good decomposition, easy to move.

Application

LGP440/50PI-22E High pressure grout injection pumps have a wide range of applications in the fields of drilling and geological exploration, mainly including the following aspects:

Formation reinforcement: By injecting slurry into the formation, the bearing capacity and stability of the formation are improved to prevent the formation from collapsing or deforming.

Water-stopping and anti-seepage: When drilling in areas with high groundwater levels, a high-pressure grouting pump can be used to inject slurry to form a water-proof curtain to prevent groundwater from seeping into the borehole or working area.

Crack repair: For cracks or cavities in the formation, a high-pressure grouting pump can be used to inject slurry for filling and repair to improve the integrity and stability of the formation.

Foundation treatment: In the foundation treatment of buildings or structures, high-pressure grouting pumps also play an important role, such as pile foundation reinforcement, foundation treatment, etc.

Formation reinforcement: By injecting slurry into the formation, the bearing capacity and stability of the formation are improved to prevent the formation from collapsing or deforming.

Water-stopping and anti-seepage: When drilling in areas with high groundwater levels, a high-pressure grouting pump can be used to inject slurry to form a water-proof curtain to prevent groundwater from seeping into the borehole or working area.

Crack repair: For cracks or cavities in the formation, a high-pressure grouting pump can be used to inject slurry for filling and repair to improve the integrity and stability of the formation.

Foundation treatment: In the foundation treatment of buildings or structures, high-pressure grouting pumps also play an important role, such as pile foundation reinforcement, foundation treatment, etc.

Features

LGP440/50PI-22E High pressure grout injection pump for drilling rig features:

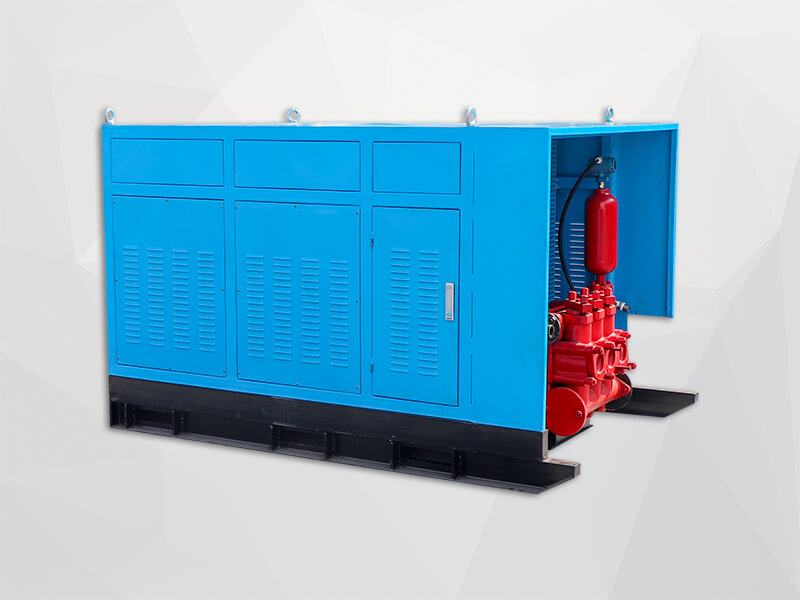

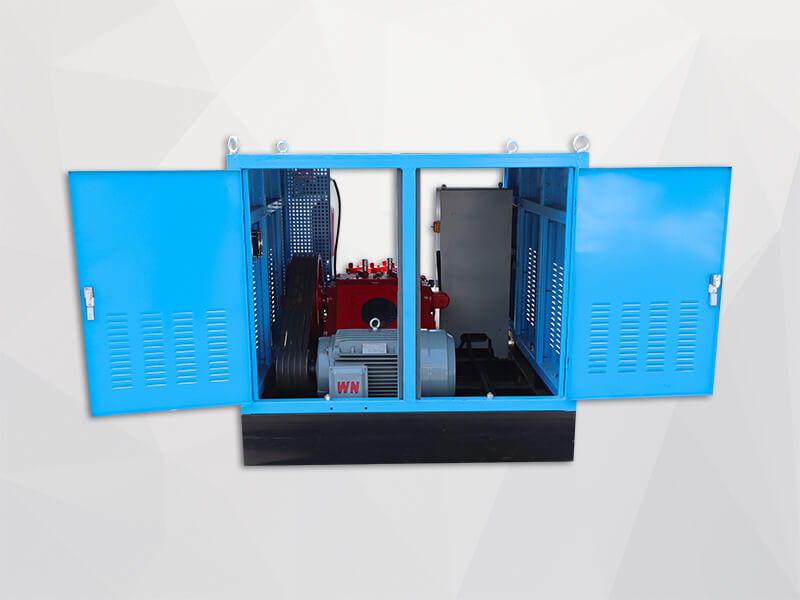

1. Frame of high pressure grout injection pump:

Maintainability: The frame is designed to be removable from the base, making maintenance tasks more accessible and convenient.Easy Access: An open door in the critical area facilitates gearbox maintenance, reducing downtime and improving overall serviceability.

Heat Dissipation: Including blinds in the design helps with efficient heat dissipation, ensuring optimal operating temperatures and protecting components from overheating.

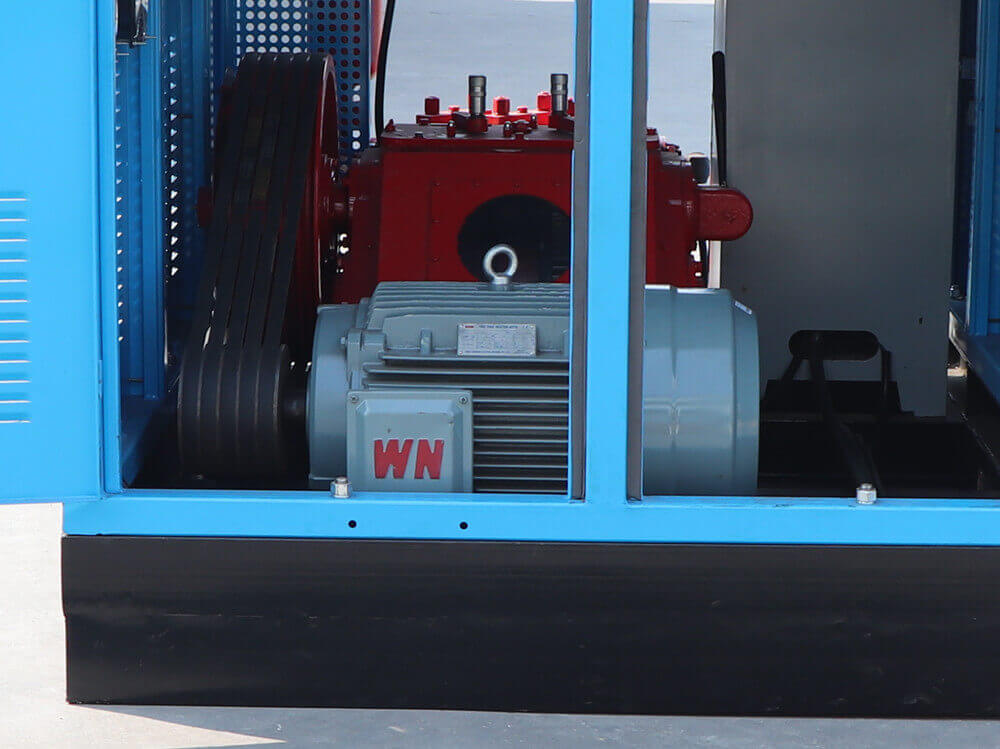

2. Power unit of grout injection pump for drilling rig:

Powerful Motor: Equipped with a 22Kw motor, it provides ample power to the gearbox through a belt drive system.Reliable Speed Regulation: Using a mature and reliable frequency converter ensures precise and efficient speed regulation.

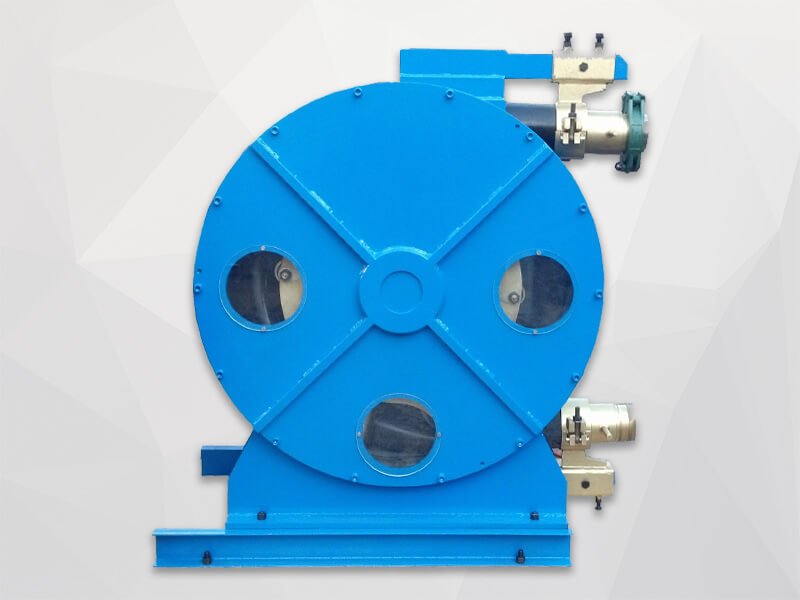

3. Gearbox of grout pump for drilling rig:

Stable Transmission: The adoption of inclined gear transmission ensures stable, safe, and reliable operation.Integrated Design: The crankcase and gearbox are integrated, enhancing structural integrity, prolonging service life, and reducing overall size and weight.

4. Grout pump of injection pump for drilling rig:

Separation Design: The pump features three separate water tanks, each with a shared suction and drainage chamber, facilitating efficient pumping operations.Durable Piston: The bowl-shaped nylon self-sealed polyurethane rubber piston improves durability and extends the service life of the pump.

Prevention Measures: Five dust seals on the pull rod prevent hydraulic mud from entering the power end and the lubricating oil filter, ensuring smooth and contamination-free operation.

Safety Feature: A relief valve automatically opens when the pressure exceeds the allowable limit, protecting the working cylinder from damage.

5. Control system of high pressure grout pump:

Versatile Control: Offers infinite variation in pressure and flow, providing precise control over pumping operations.Advanced AI Control: Incorporates advanced artificial intelligence for intuitive display and control of pressure numbers, along with instant flow display and accumulation functionality, ensuring safe and easy operation.

Overall, this high pressure injection pump equipment combines robust construction, high-performance components, and advanced control systems to deliver reliable, efficient, and user-friendly grouting solutions.

Product Details

Technical Parameters

Technical Data

| Model | LGP440/50PI-22E grout injection pump for drilling rig | |||

| Modality | Horizontal three-cylinder reciprocating single-action piston pump | |||

| Cylinder diameter (mm) | 100 | Cylinder stroke (mm) | 110 | |

| Power (Kw) | 22 | Pump speed (r/min) | 214 | |

| Max. Output (L/min) | 440 | Max. Pressure (MPa) | 5 | |

| Inlet diameter (mm) | 89 | Outlet diameter (mm) | DN40 | |

| Size(L×W×H) (mm), Weight (Kg) | 2050*1370*1310, 1365 | |||

| Data: 1. All data are tested by water. 2. We can customize products according to your requirements. |

||||

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

Working principle of high pressure jet grouting pump is to inject high pressure fluid (usually cement slurry) into the ground through a nozzle, eroding and mixing the in-situ soil and cement slurry to form a solidified body called a soil-cement column or slab. This process is usually called jet grouting.LGP250/450-250D High pressure jet grouting pump

Working principle of high pressure jet grouting pump is to inject high pressure fluid (usually cement slurry) into the ground through a nozzle, eroding and mixing the in-situ soil and cement slurry to form a solidified body called a soil-cement column or slab. This process is usually called jet grouting.LGP250/450-250D High pressure jet grouting pump -

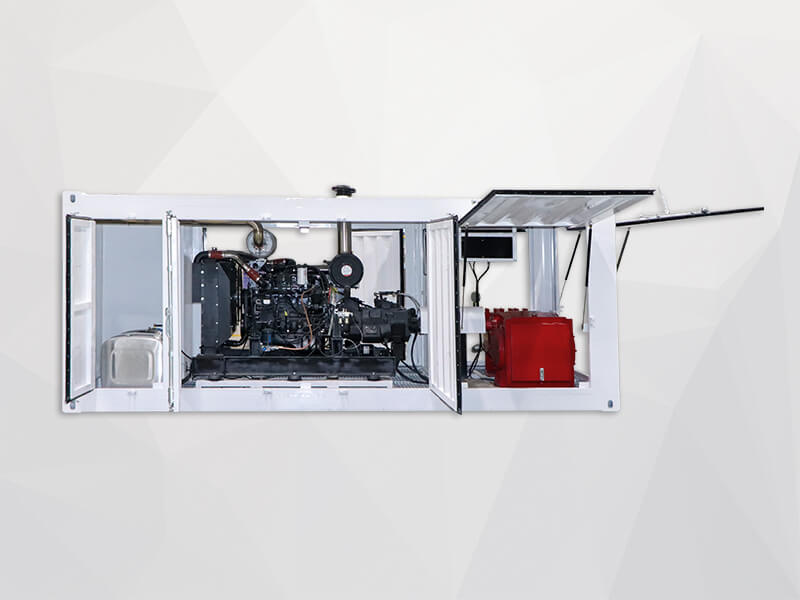

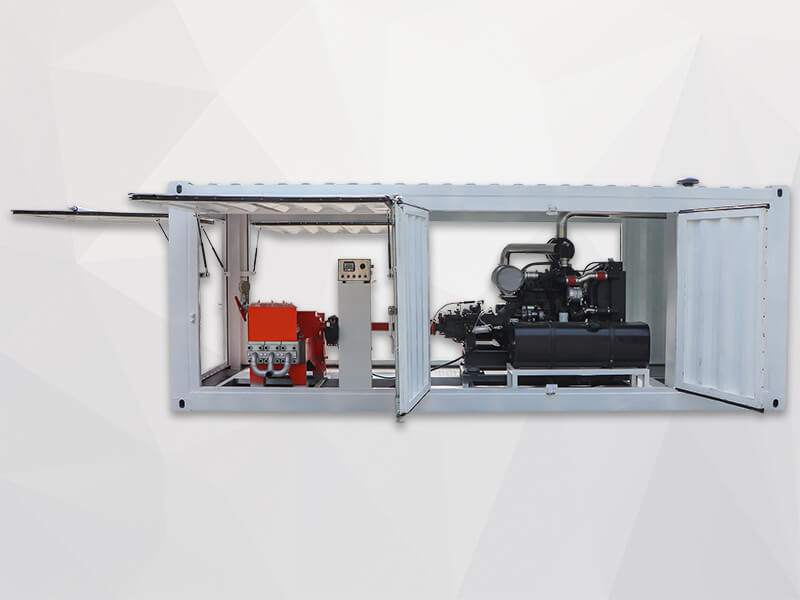

Diesel driven jet grouting pump in 20ft container provides high-pressure power for various construction projects, including strengthening weak foundations in new buildings, highways, high-speed railways, and underground railways.LGP114/500-120D Diesel driven jet grouting pump in 20ft container

Diesel driven jet grouting pump in 20ft container provides high-pressure power for various construction projects, including strengthening weak foundations in new buildings, highways, high-speed railways, and underground railways.LGP114/500-120D Diesel driven jet grouting pump in 20ft container -

LGM50/80PLD-E Double-Plunger hydraulic Grout Pump is designed with two low-wear plungers pump. With the features of double acting, ball valves, low pressure surge, variable pressure and flow. Therefore, this pump is suitable for all grouting work, up to 8mm particle size , such as, for the pumping of backfill mortar behind tunnel liners, grouting in soil, earth foundation stabilization, waterproofing, tunnel lining, underwater foundations, bridge decks, deep well casing, slope line grouting, etc.LGM80/50PLD-E Double plunger hydraulic grout pump

LGM50/80PLD-E Double-Plunger hydraulic Grout Pump is designed with two low-wear plungers pump. With the features of double acting, ball valves, low pressure surge, variable pressure and flow. Therefore, this pump is suitable for all grouting work, up to 8mm particle size , such as, for the pumping of backfill mortar behind tunnel liners, grouting in soil, earth foundation stabilization, waterproofing, tunnel lining, underwater foundations, bridge decks, deep well casing, slope line grouting, etc.LGM80/50PLD-E Double plunger hydraulic grout pump -

China injection vertical grout pump is designed and made for permeation grouting, compaction grouting, backfilling grouting, curtain grouting, high pressure split grouting etc., grouting methods.LDH75/100PI-E injection vertical grout pump

China injection vertical grout pump is designed and made for permeation grouting, compaction grouting, backfilling grouting, curtain grouting, high pressure split grouting etc., grouting methods.LDH75/100PI-E injection vertical grout pump

.jpg)

.jpg)