Your position:

Home > Products > Grout Mixing Plant

LGP400/700/80PL-E All-in-one grout plant

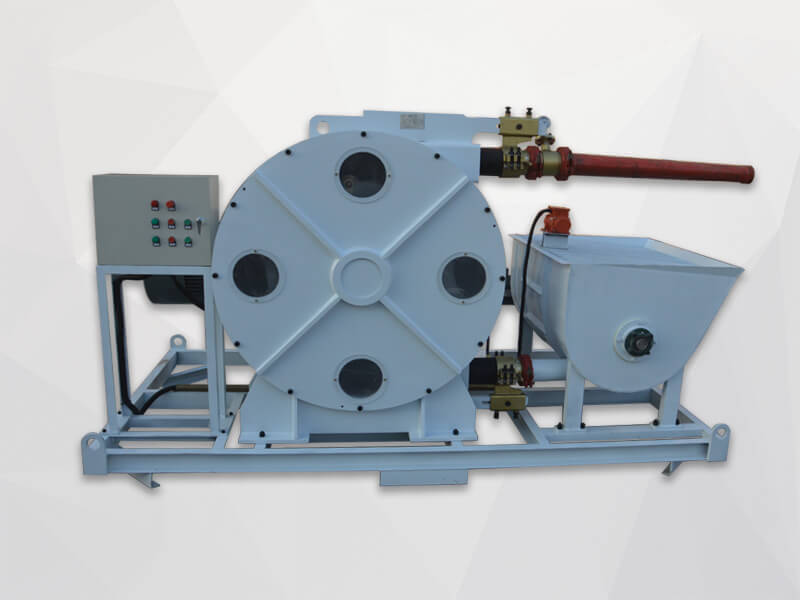

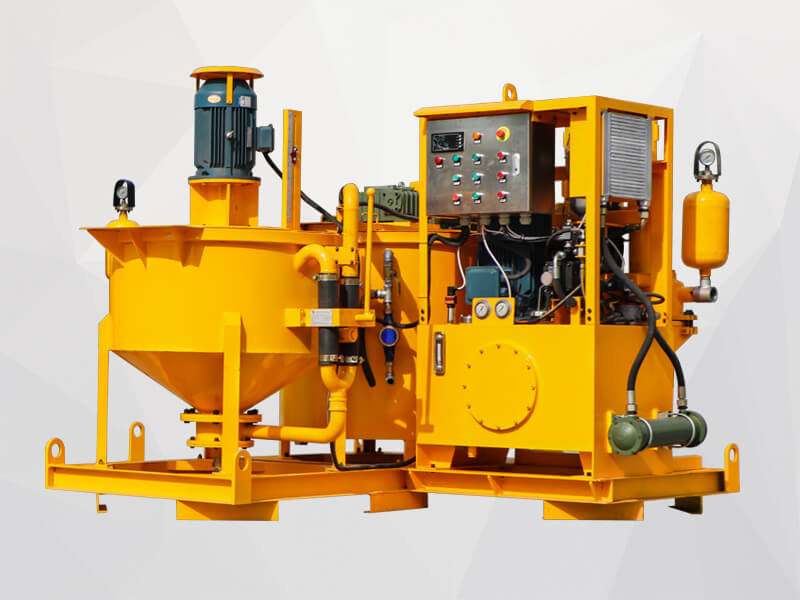

LGP400/700/80DPL-E All-in-one grout plant is a combination of mixer, agitator and grout pump in one base frame. It is used for ement mixing and grouting projects and with high shear high speed grout mixer volume, the mixer volume is 400L, agitator volume is 700L, grouting pressure and displacement is adjustable, low pressure: 0-80L/min, 0-25bar; high pressure: 0-58L/min, 0-40bar. The all in one grout plant is hydraulic drive with electric motor.

LGP400/700/80DPL-E

2350*2100*1830mm

1530kg

400L

700L

Low pressure: 0-80L/min, 0-25bar, High pressure: 0-58L/min, 0-40bar

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

LGP400/700/80DPL-E All-in-one grout plant is a combination of mixer, agitator and grout pump in one base frame. It is used for ement mixing and grouting projects and with high shear high speed grout mixer volume, the mixer volume is 400L, agitator volume is 700L, grouting pressure and displacement is adjustable, low pressure: 0-80L/min, 0-25bar; high pressure: 0-58L/min, 0-40bar. The all in one grout plant is hydraulic drive with electric motor.

High speed vortex mixer ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry. Then the mixed slurry is delivered to the agitator. Grout pump injects from the mixing drum (storage tank). This ensures a continuous mixing and grouting operations. What's more, the double-cylinder pump together with the pressure-holding system is used, so that the pump automatically stops and maintains the very little pressure impulse (1-4bar with 50bar grouting pressure) to ensure that the grouting hole is completely filled.

Lead Equipment has many years'experience in manufacture and marketing of all in one grout unit as well as specific customer application requirements for grouting. Capacity and power could be customizing according to your grouting projects.

High speed vortex mixer ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry. Then the mixed slurry is delivered to the agitator. Grout pump injects from the mixing drum (storage tank). This ensures a continuous mixing and grouting operations. What's more, the double-cylinder pump together with the pressure-holding system is used, so that the pump automatically stops and maintains the very little pressure impulse (1-4bar with 50bar grouting pressure) to ensure that the grouting hole is completely filled.

Lead Equipment has many years'experience in manufacture and marketing of all in one grout unit as well as specific customer application requirements for grouting. Capacity and power could be customizing according to your grouting projects.

Application

Civil engineering - all in one grout mixing plant is used for dam, tunnel, subway, mine, soil nailing wall, curtain, anchor, cable trench and anchor grouting.

Engineering - all-in-one grout plant is used for underwater foundation, offshore platform, coast foundation grouting reinforcement.

Building structure - all in one grout mixing and pumping system is used for building and bridge repair, foundation reinforcement, slope support, soil compaction, rock grouting.

Mine application - all-in-one grout plant is used for roadway reinforcement, backfill, waterproof grouting.

Engineering - all-in-one grout plant is used for underwater foundation, offshore platform, coast foundation grouting reinforcement.

Building structure - all in one grout mixing and pumping system is used for building and bridge repair, foundation reinforcement, slope support, soil compaction, rock grouting.

Mine application - all-in-one grout plant is used for roadway reinforcement, backfill, waterproof grouting.

Features

1. Up to 5mm particle size.

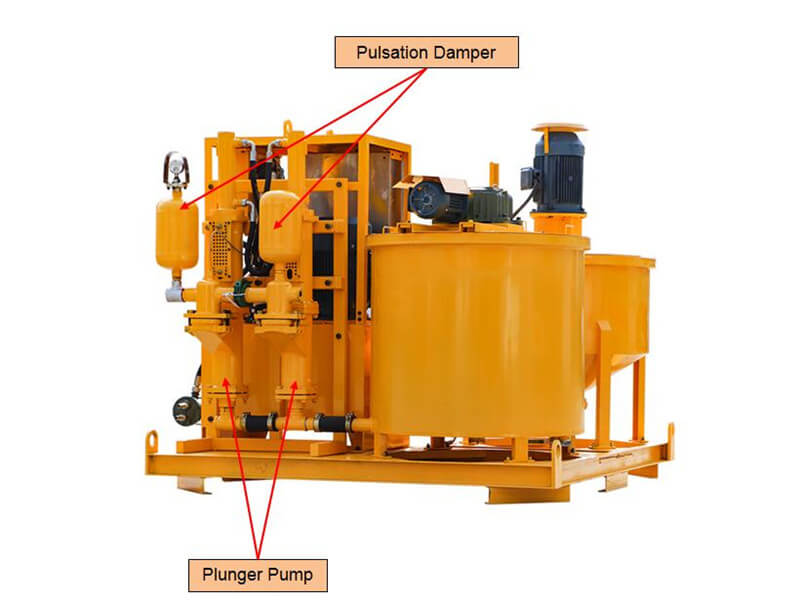

2. Pressure holding system.

3. Low flow pressure surge system.

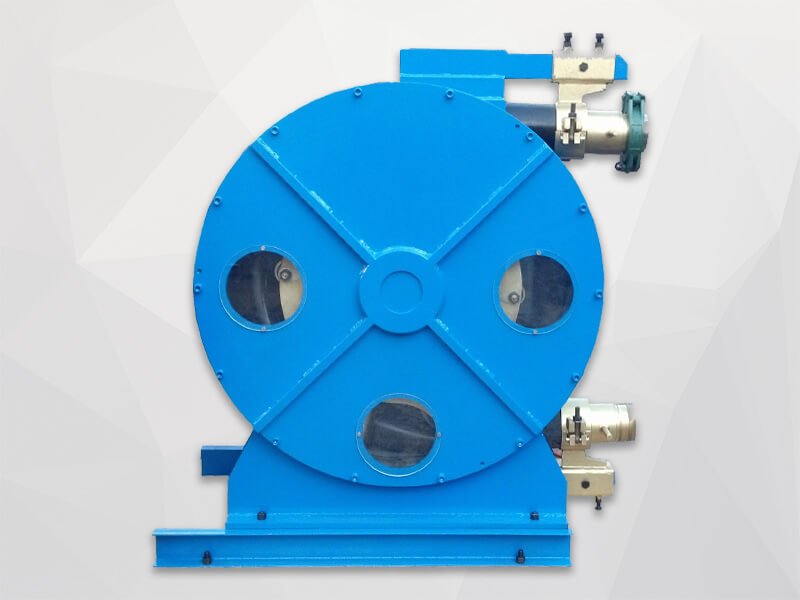

4. Double plunger pump.

5. With the liquid level of the mixer tank.

6. High-speed colloidal grout mixer.

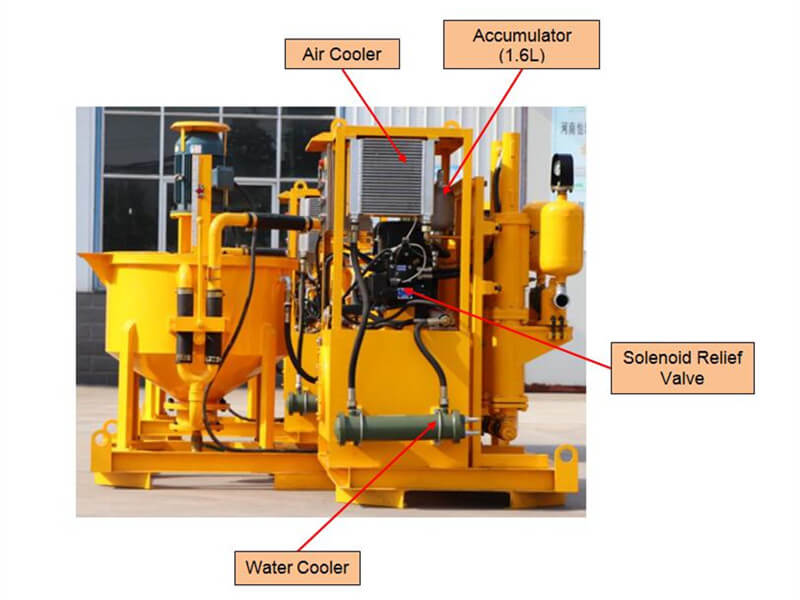

7. Hydraulic drive (safely releasing pressure when pumping block).

8. Vertical type pump with compact size.

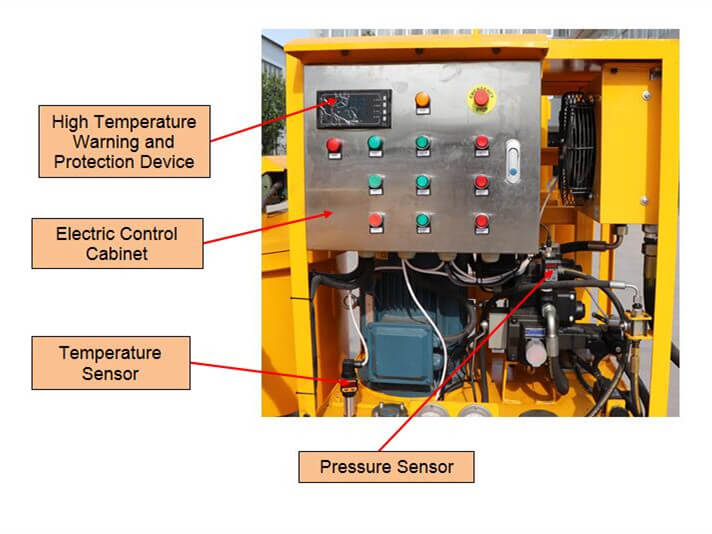

9. Hydraulic system with high temperature warning and protection system.

10. Air cooler and water cooler (suitable for working in tropical and sub-hot areas).

2. Pressure holding system.

3. Low flow pressure surge system.

4. Double plunger pump.

5. With the liquid level of the mixer tank.

6. High-speed colloidal grout mixer.

7. Hydraulic drive (safely releasing pressure when pumping block).

8. Vertical type pump with compact size.

9. Hydraulic system with high temperature warning and protection system.

10. Air cooler and water cooler (suitable for working in tropical and sub-hot areas).

Product Details

Technical Parameters

Technical Data

| Description | Data |

| All-in-one grout plant model | LGP400/700/80DPL-E |

| Dimensions | 2350*2100*1830mm |

| Weight | 1530kg |

| Mixer | |

| Capacity | 400L |

| Recycling discharge | 1100L/min |

| Suitable water/cement ratio | ≥0.5:1 |

| Motor power | 7.5Kw |

| Rated Rev. | 1450rpm |

| Agitator | |

| Capacity | 700L |

| Motor model | 1.5Kw |

| Rated Rev. | 36rpm |

| Pump(vertical compact hydraulic grout pump) | |

| Output/pressure | Low pressure: 0-80L/min, 0-25bar High pressure: 0-58L/min, 0-40bar |

| Power | 11Kw |

| We could also customize all-in-one grout plant according to your demands. | |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

Colloidal grout mixer pump unit is a combination of grout mixer, grout agitator and double cylinders piston pump with single acting in one base frame. It makes a very versatile and efficient piece of the grout equipment. Each colloidal grout mixer pump unit incorporates mixers and pumps of matched volume capacity which together with an agitated storage tank enable virtually continuous operation once work has commenced. Grouting pressure and displacement is adjustable.LGP400/700/80/100DPI-D Colloidal grout mixer pump unit

Colloidal grout mixer pump unit is a combination of grout mixer, grout agitator and double cylinders piston pump with single acting in one base frame. It makes a very versatile and efficient piece of the grout equipment. Each colloidal grout mixer pump unit incorporates mixers and pumps of matched volume capacity which together with an agitated storage tank enable virtually continuous operation once work has commenced. Grouting pressure and displacement is adjustable.LGP400/700/80/100DPI-D Colloidal grout mixer pump unit -

LGP1200/3000/300H-E Grout plant unit is a simple grout plant, also called mixing and grouting plant, it is used for grouting and backfilling in ground and underground construction or TBM project. It consists of colloidal grout mixer, agitator tank, continuously variable hose pump in one frame.LGP1200/3000/300H-E Grout plant unit

LGP1200/3000/300H-E Grout plant unit is a simple grout plant, also called mixing and grouting plant, it is used for grouting and backfilling in ground and underground construction or TBM project. It consists of colloidal grout mixer, agitator tank, continuously variable hose pump in one frame.LGP1200/3000/300H-E Grout plant unit -

Cement grout mixing plant is a combination of 500L mixer, 2000L agitator, 165L/min hose pump and weighing modules and PLC control system in one plant, it is used for for mixing and pumping water, cement, bentonite, silicates and other additives. LGP500/2000/165H-E is specially customized for our Mongolian customersLGP500/2000/165H-E Cement grout plant

Cement grout mixing plant is a combination of 500L mixer, 2000L agitator, 165L/min hose pump and weighing modules and PLC control system in one plant, it is used for for mixing and pumping water, cement, bentonite, silicates and other additives. LGP500/2000/165H-E is specially customized for our Mongolian customersLGP500/2000/165H-E Cement grout plant -

LGP400/700/320/100TPI-E grout mixing station consists of a mixing tank, an agitator tank and a high-pressure slurry pump, it is a whole unit plant of mixing, agitating and grouting to make bentonite slurry, cement slurry, etc. and then grouting the slurry under high pressure in the application construction, mining, railway, hydropower, highway and other ground and underground construction.LGP400/700/320/100TPI-E Grout mixing station

LGP400/700/320/100TPI-E grout mixing station consists of a mixing tank, an agitator tank and a high-pressure slurry pump, it is a whole unit plant of mixing, agitating and grouting to make bentonite slurry, cement slurry, etc. and then grouting the slurry under high pressure in the application construction, mining, railway, hydropower, highway and other ground and underground construction.LGP400/700/320/100TPI-E Grout mixing station

.jpg)

.jpg)