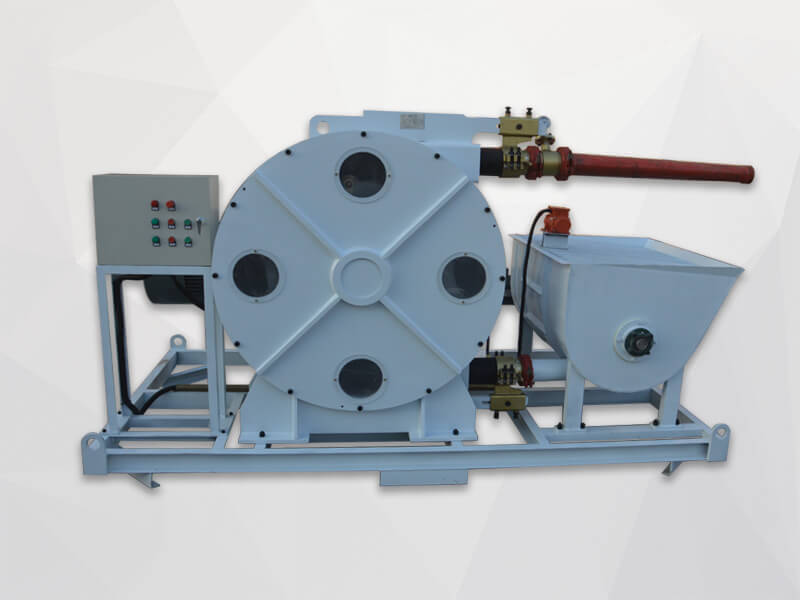

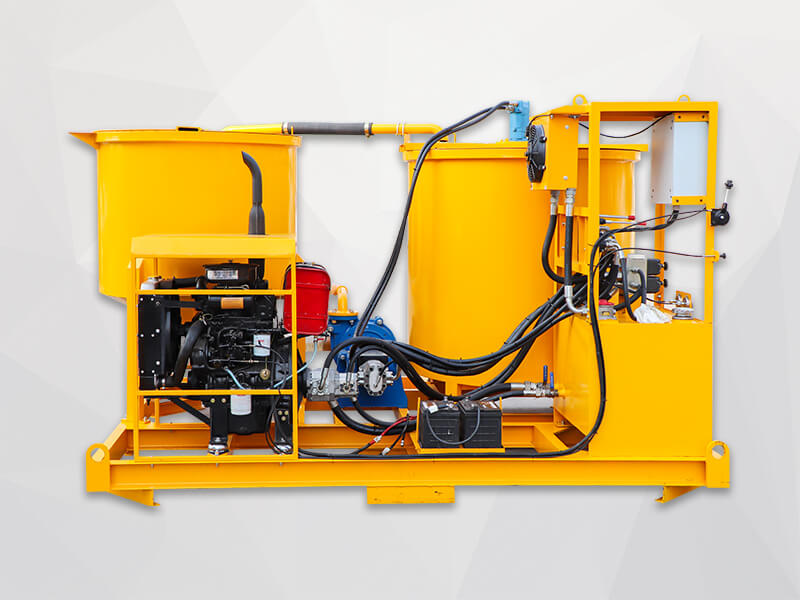

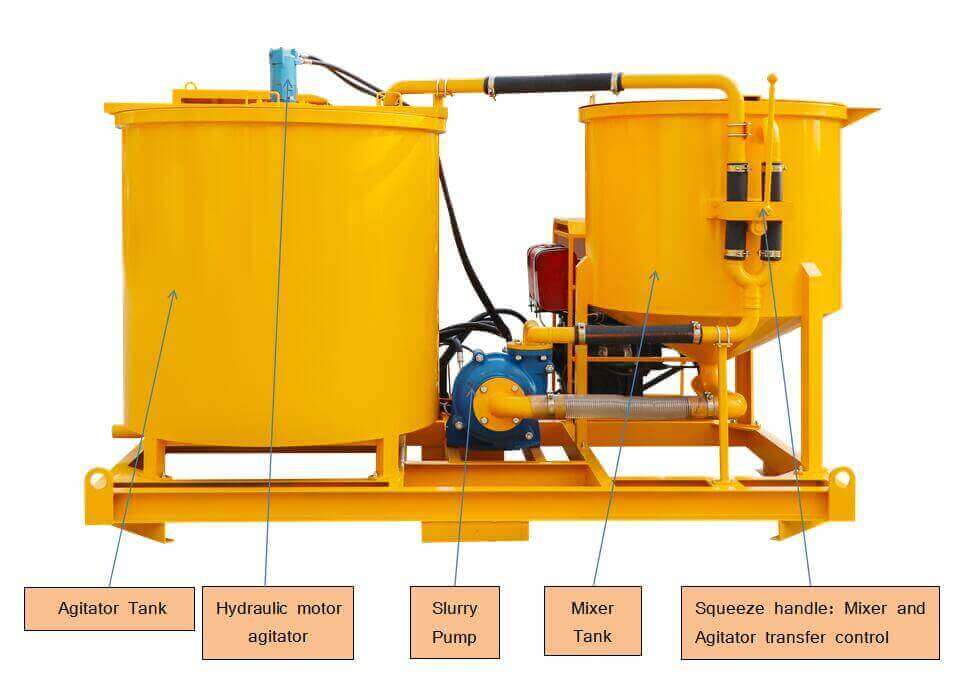

LMA800-1500D Diesel engine cement grout mixer with agitator combines a 800L steel sheet cylindrical mixer tank, a heavy-duty slurry pump and a 1500L agitator tank, set up on a strong base frame, it is mainly driven by a 26 Kw diesel engine, and can mix various types of grout which can includes cement, ultra-fine cement, bentonite and other admixtures.

Working principle of LMA800-1500D Diesel engine cement grout mixer:

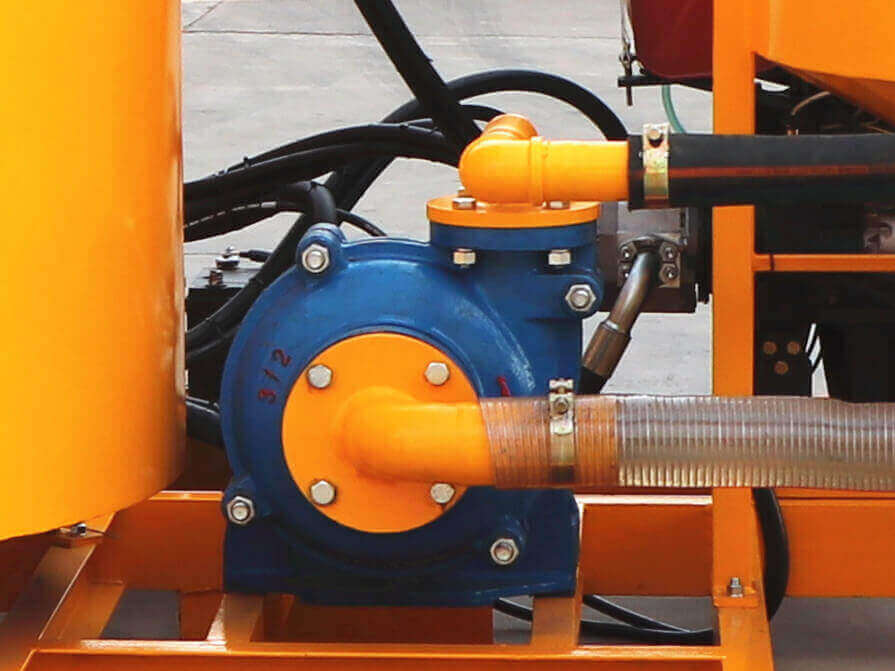

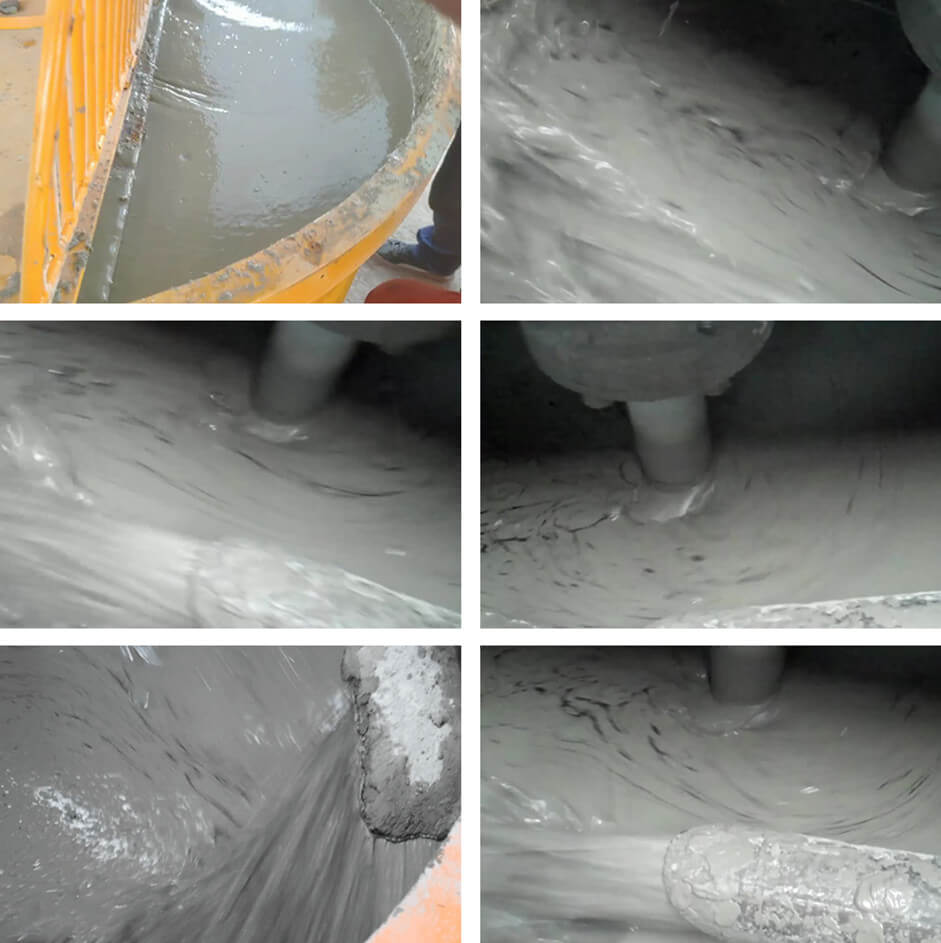

1. The slurry is mixed through a high-speed vortex produced by a special pump which, after sucking the material from the bottom of the mixer tank, sends it back tangentially into the same tank to get the highest possible efficiency. By this process, it is possible to obtain homogeneous colloidal and high-quality mixtures within a very short time.

2. After mixing, this mixture is pumped into the agitator tank with slow-speed mixing paddles by the above same pump.

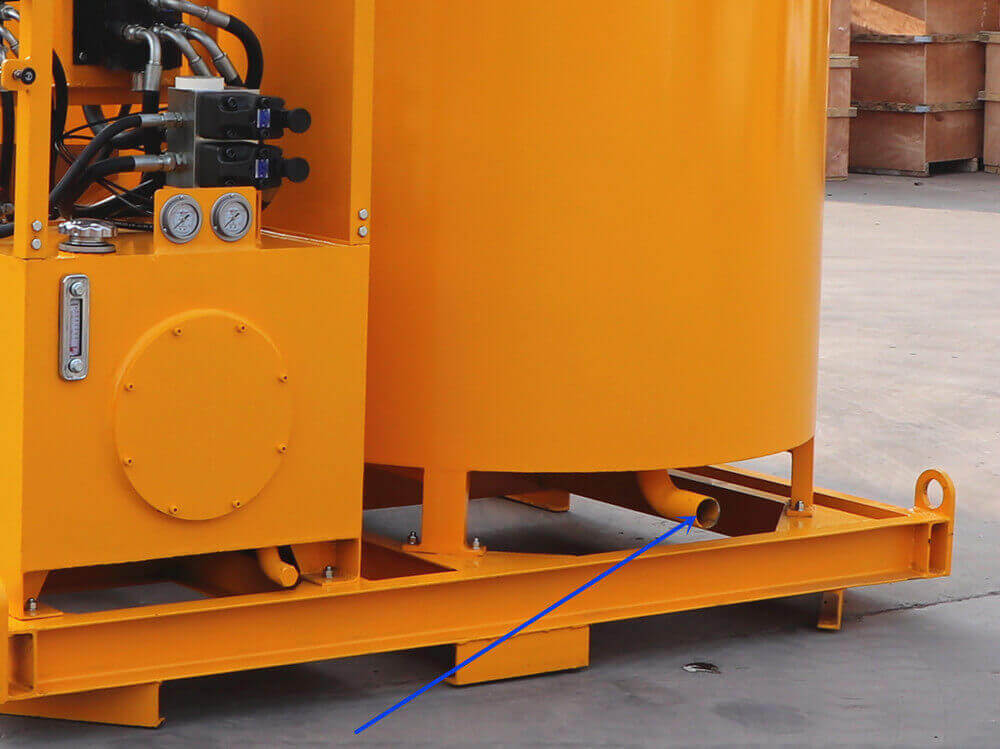

3. When the mixtures in the mixer tank are completely pumped out, shift the specially design handle valve to continue to mix the next cycle slurry.

2. Simple structure, easy assemble;

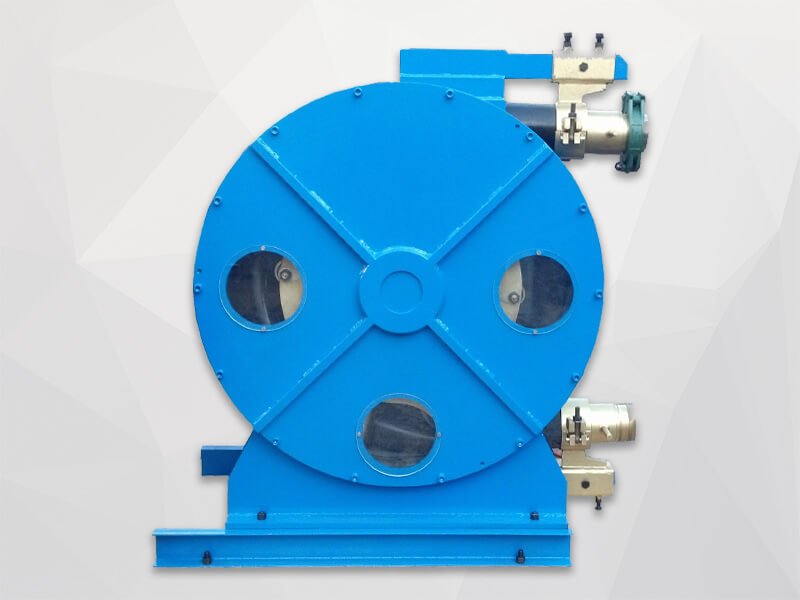

3. Mixer and agitator switch by using squeeze handle, great reliability and simple to operate;

4. The diesel engine has strong power, paired with hydraulic systems, and the usage scenarios of the equipment are more flexible and diverse.

| Model | LMA800-1500D grout mixer |

| Output | 11~14m3/h |

| Mixer volume | 800L |

| Agitator volume | 1500L |

| Pump delivery output | 700L/min |

| Diesel engine power | 26 Kw |

| Cooling | Water |

| Overall dimension | 3210*2200*1910mm |

| Weight | 1650KG |

| We reserve the right to change technical specifications without prior notice. | |

Packaging and delivery picturers:

More cement grout mixers for choose:

-

Container type grout mixer with agitator is used for mixing grout materials include cement, water, additive and bentonite. It has compact structure, and is simple operation and easy maintenance.LMA2X300/1000 Container type grout mixer with agitator

Container type grout mixer with agitator is used for mixing grout materials include cement, water, additive and bentonite. It has compact structure, and is simple operation and easy maintenance.LMA2X300/1000 Container type grout mixer with agitator -

Automatic cement bentonite mud mixing batching station finds application in various construction projects that require the use of cement bentonite mud. It is commonly used in the construction of cutoff walls, diaphragm walls, slurry walls, and other geotechnical applications where the containment of soil and groundwater is necessary.LMA20 Automatic cement bentonite mud mixing batching station with cement silo in container

Automatic cement bentonite mud mixing batching station finds application in various construction projects that require the use of cement bentonite mud. It is commonly used in the construction of cutoff walls, diaphragm walls, slurry walls, and other geotechnical applications where the containment of soil and groundwater is necessary.LMA20 Automatic cement bentonite mud mixing batching station with cement silo in container -

LMA400-700AW automatic grout mixer can also work with the agitator. The agitator has two functions, one is to avoid precipitation, and the other is to store the mixed cement slurry. In this case, stirring work and continuous grouting can be carried out.LMA400-700AW Automatic grout mixer

LMA400-700AW automatic grout mixer can also work with the agitator. The agitator has two functions, one is to avoid precipitation, and the other is to store the mixed cement slurry. In this case, stirring work and continuous grouting can be carried out.LMA400-700AW Automatic grout mixer -

LMA1500-1200E Cement grout mixer is a combination consist of a steel sheet cylindrical mixer tank heavy-duty slurry pump and agitator tank, set-up on a strong base frame. This cement grout mixer for sale is equipped with an automatic control system that can automatically control the operation of the equipment.LMA1500-1200E Cement grout mixer for sale

LMA1500-1200E Cement grout mixer is a combination consist of a steel sheet cylindrical mixer tank heavy-duty slurry pump and agitator tank, set-up on a strong base frame. This cement grout mixer for sale is equipped with an automatic control system that can automatically control the operation of the equipment.LMA1500-1200E Cement grout mixer for sale

.jpg)

.jpg)