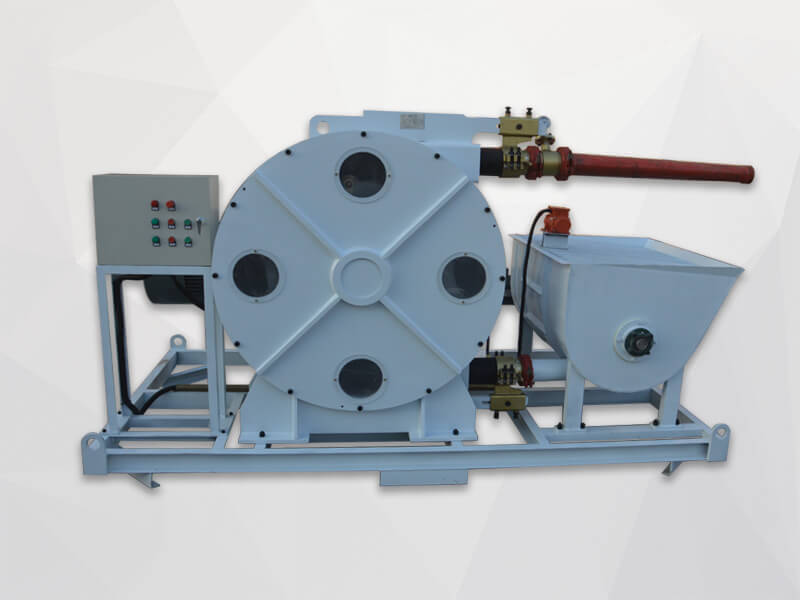

LCPM Hydraulic discharge vertical shaft planetary mixer is widely used for refractory material production line, cement product production line, PC prefabricated component production line, block production line, etc.

The vertical shaft planetary concrete mixer is equipped with a hydraulic discharge door, which can be used to stir UHPC and refractory materials and other materials. Unlike conventional mixers, the planetary concrete mixer employs a unique blending mechanism characterized by the concurrent utilization of both revolution and rotation motions in its mixing blades. This distinctive blade movement traces a comprehensive path that spans the full circumference of the mixing drum, thereby ensuring thorough, gapless mixing throughout the entire volume of the mixer barrel – a phenomenon known as "zero-dead-angle mixing."

The mixing blades in a planetary mixer for UHPC and Refractory ingeniously harness the dual principles of revolution and rotation to execute their task. As they revolve around the central axis of the mixing drum, they simultaneously rotate on their own axes, generating an intricate, multidimensional motion pattern. This complex trajectory enables the blades to interact with every inch of the drum's interior surface, effectively sweeping across all corners and crevices.

The motion track traced by these blades is exhaustive, encompassing the entire length, width, and height of the mixing barrel. It ensures that no area remains untouched or unincorporated into the blending process, eliminating any potential 'dead angles' where material might otherwise stagnate or remain inadequately mixed. This comprehensive coverage is the defining characteristic of zero-dead-angle mixing, which sets hydraulic discharge vertical shaft planetary concrete mixers apart from their conventional counterparts.

In summary, the vertical shaft UHPC and refractory planetary mixer's innovative application of mixing blades that utilize both revolution and rotation principles, combined with their ability to traverse the full extent of the mixing barrel, guarantees unparalleled mixing efficiency. This design achieves complete, uniform blending without any blind spots, thus realizing the concept of zero-dead-angle mixing within the mixer drum.

| LCPM Hydraulic Discharge Vertical Shaft Planetary Mixer can be used to stir the following materials: | |

| Concrete | Ready-mix concrete, precast concrete, foam concrete, color concrete, light concrete. |

| Refractory | Tap hole clay, refractory brick, castable. |

| Ceramic | Ceramic brick, ceramix plate. |

| Other | Glass, waste treatment. |

Our Services about the LCPM Hydraulic discharge vertical shaft planetary mixer for UHPC and Refractory:

1. Warranty

Leadcrete Equipment extends to our esteemed clientele a comprehensive warranty spanning twelve months or 2000 operating hours, applicable to any machinery procured from us. Throughout this warranty period, should any defects in materials or craftsmanship arise within spare parts during normal usage, we undertake to repair or replace the affected component at no cost, at our discretion.

2. Spare Parts

Pmixers is steadfastly committed to furnishing our clients with genuine spare parts of unparalleled quality, precise compatibility, and optimal functionality. Leveraging our expansive global distribution network, we assure prompt delivery and exceptional service, regardless of your location. To initiate your spare parts request, kindly forward it to us, inclusive of the product name, model, equipment serial number, and a description of the required parts. We pledge to promptly and aptly attend to your inquiry.

3. Training

Leadcrete Equipment boasts state-of-the-art facilities and a conducive learning environment, enabling us to deliver bespoke training services to diverse user profiles. Our training repertoire encompasses product familiarization, operational training, maintenance techniques, technical expertise tutorials, and additional customized modules, all meticulously designed to address your unique requirements. These training programs can be executed either at our factory premises or on-site at the client's convenience.

4. Technical Advice

Leadcrete Equipment further extends its support by facilitating access to seasoned service professionals who can impart to you in-depth, comprehensive knowledge pertinent to your specific machinery. By availing of our technical guidance, you can anticipate a substantial extension of your machine's service life, coupled with sustained high-performance capabilities.

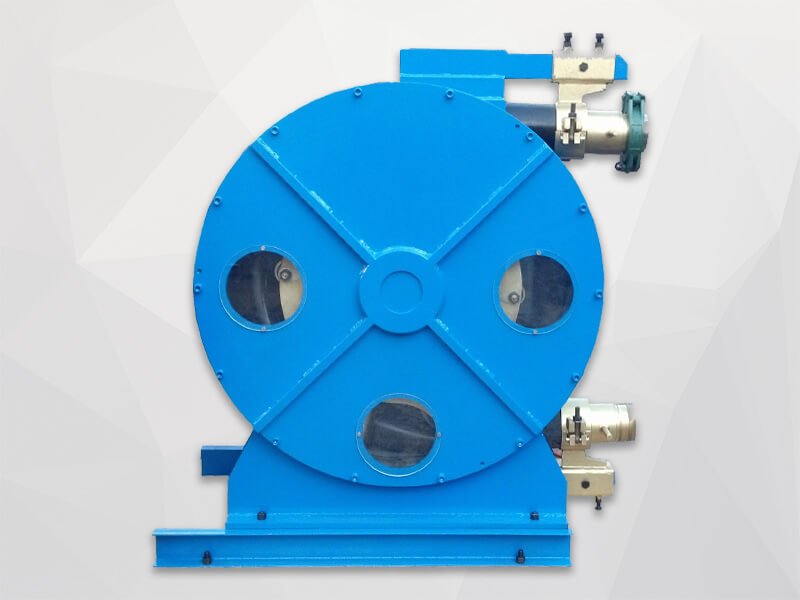

Features of LCPM Hydraulic discharge vertical shaft planetary mixer for UHPC and Refractory:

1. Steady driving

The power transmission is realized by a hard surface gearbox

2. High mixing efficiency

The gear box drives the mixing arms to move with complex track, and the mixing is turbulent, then the mixer works more effectively.

3. Homogeneous mixing

Mixing blades are composed of several groups of mixing arms, which covers the entire mixing region.

Both revolution and rotation of mixing blades ensure the homogeneity of the material. As the picture shows, mixing blades’ motion track covers the whole drum after a cycle.

4. Multiple discharging method

According to various demands of customers, the discharging door can be operated hydraulically, pneumatically or manually.

5. Special designed water sprayer

Special designed sprayer makes the water cloud cover more area and ensure the even distribution of the materials.

6. Easy to maintain and no leakage problem

Transmission system (including motor) is located at the top of mixing drum, completely separated from the concrete. It's convenient for maintenance and there is no leakage problem at the shaft end.

| Item | LCPM50 | LCPM100 | LCPM150 | LCPM250 | LCPM330 | LCPM500 | LCPM750 |

| Feeding Volume (L) | 75 | 150 | 225 | 375 | 500 | 750 | 1125 |

| Feeding Capacity (Kg) | 120 | 240 | 360 | 600 | 790 | 1200 | 1800 |

| Output Volume (L) | 50 | 100 | 150 | 250 | 330 | 500 | 750 |

| Mixing Power (Kw) | 3 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 |

| Mixing Star*Blade | 1*2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*3 | 1*3 |

| Side Scraper | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Discharge Scraper | - | - | 1 | 1 | 1 | 1 | 1 |

| Discharging Power (KW) | Pneumatic Discharging Door (Hydraulic Discharge Door Optional) | ||||||

| Weight (Kg) | 750 | 1000 | 1300 | 1500 | 2000 | 2400 | 3900 |

| Item | LCPM1000 | LCPM1250 | LCPM1500 | LCPM2000 | LCPM2500 | LCPM3000 | LCPM4000 |

| Feeding Volume (L) | 1500 | 1875 | 2250 | 3000 | 3750 | 4500 | 6000 |

| Feeding Capacity (Kg) | 2400 | 3000 | 3600 | 4800 | 6000 | 7250 | 9600 |

| Output Volume (L) | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Mixing Power (Kw) | 37 | 45 | 55 | 75 | 90 | 110 | 132 |

| Mixing Star*Blade | 2*3 | 2*3 | 2*3 | 3*3 | 3*3 | 3*3 | 3*3 |

| Side Scraper | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Discharge Scraper | 1 | 1 | 1 | 2 | 2 | 2 | 2 |

| Discharging Power (KW) | 3 | 3 | 3 | 4 | 4 | 4 | 4 |

| Weight (Kg) | 5500 | 6000 | 6500 | 9200 | 11000 | 12000 | 17500 |

-

Capacity 250kg (or an equivalent amount of 250L) pan type refractory mixer is suitable for the mixing needs of small and medium-sized refractory materials.LRM250 250kg pan type refractory mixer

Capacity 250kg (or an equivalent amount of 250L) pan type refractory mixer is suitable for the mixing needs of small and medium-sized refractory materials.LRM250 250kg pan type refractory mixer -

LRM refractory castable mixers are designed by refractory castable mixer manufacturer Lead Equipment for mixing refractory materials, castable materials, etc.LRM 100kg 250kg 500kg Refractory Castable Pan Mixer

LRM refractory castable mixers are designed by refractory castable mixer manufacturer Lead Equipment for mixing refractory materials, castable materials, etc.LRM 100kg 250kg 500kg Refractory Castable Pan Mixer -

LRM100 100kg refractory castable mixer is built with robust materials to withstand the harsh conditions of refractory mixing and ensure long-lasting performance. Mixing capacity is 100Kg per batch, rotating speed is 33rpm.LRM100 100kg refractory castable mixer

LRM100 100kg refractory castable mixer is built with robust materials to withstand the harsh conditions of refractory mixing and ensure long-lasting performance. Mixing capacity is 100Kg per batch, rotating speed is 33rpm.LRM100 100kg refractory castable mixer -

A 500kg capacity refractory paddle mixer is a specialized piece of equipment designed for the preparation of large volumes of refractory materials, such as concrete, mortars, and castables.LRM500 500kg capacity refractory paddle mixer

A 500kg capacity refractory paddle mixer is a specialized piece of equipment designed for the preparation of large volumes of refractory materials, such as concrete, mortars, and castables.LRM500 500kg capacity refractory paddle mixer

.jpg)

.jpg)