Your position:

Home > Products > Refractory Pan Mixer

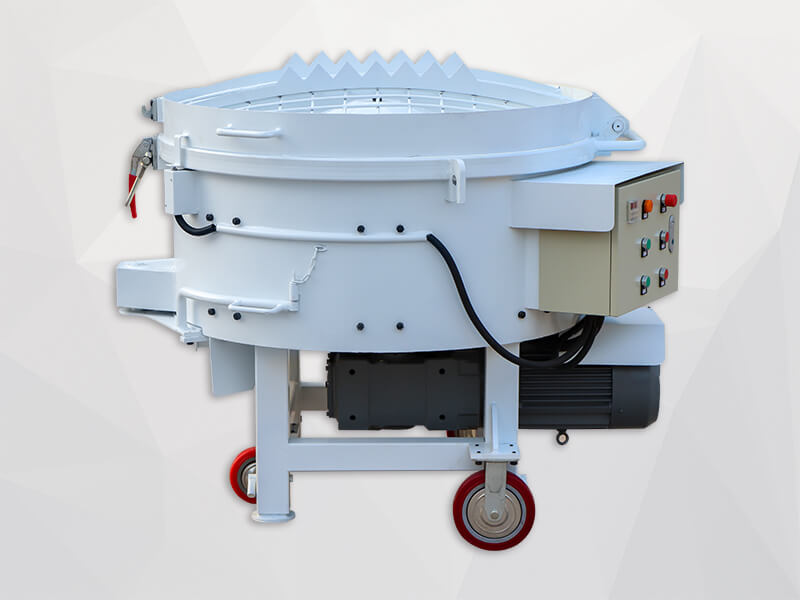

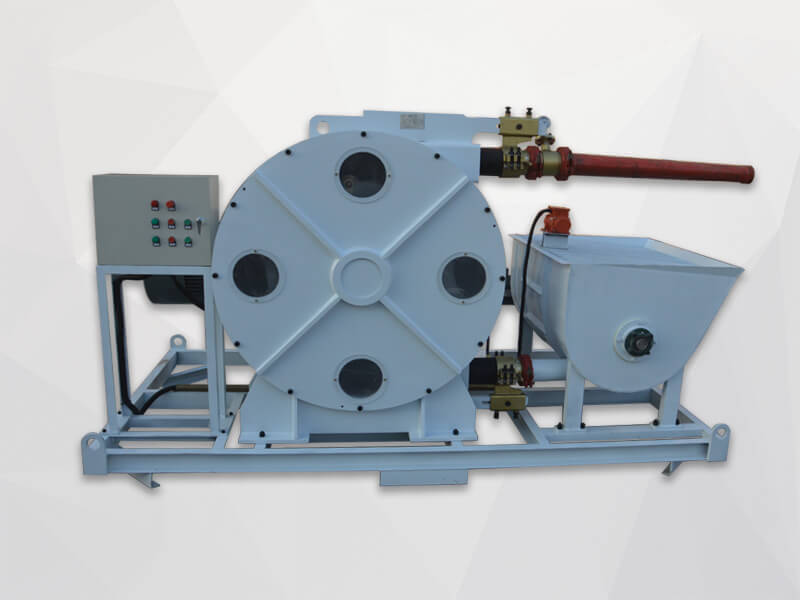

LRM100 100kg refractory castable mixer

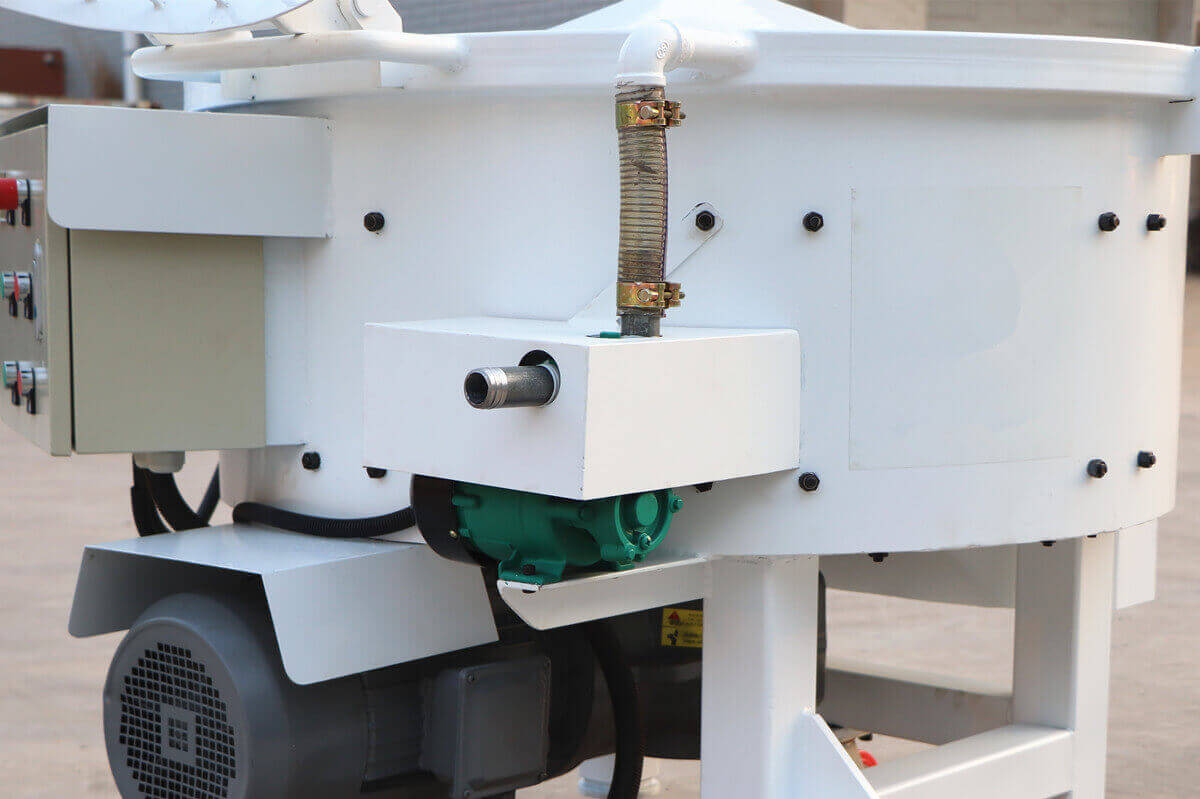

LRM100 100kg refractory castable mixer is built with robust materials to withstand the harsh conditions of refractory mixing and ensure long-lasting performance. Mixing capacity is 100Kg per batch, rotating speed is 33rpm.

LRM100

100kg

33rpm

4kw

1100mm

1400x1300x1100mm

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

LRM100 100kg refractory castable mixer is mainly used for mixing refractory materials. Its design and characteristics make it widely used in the refractory industry.

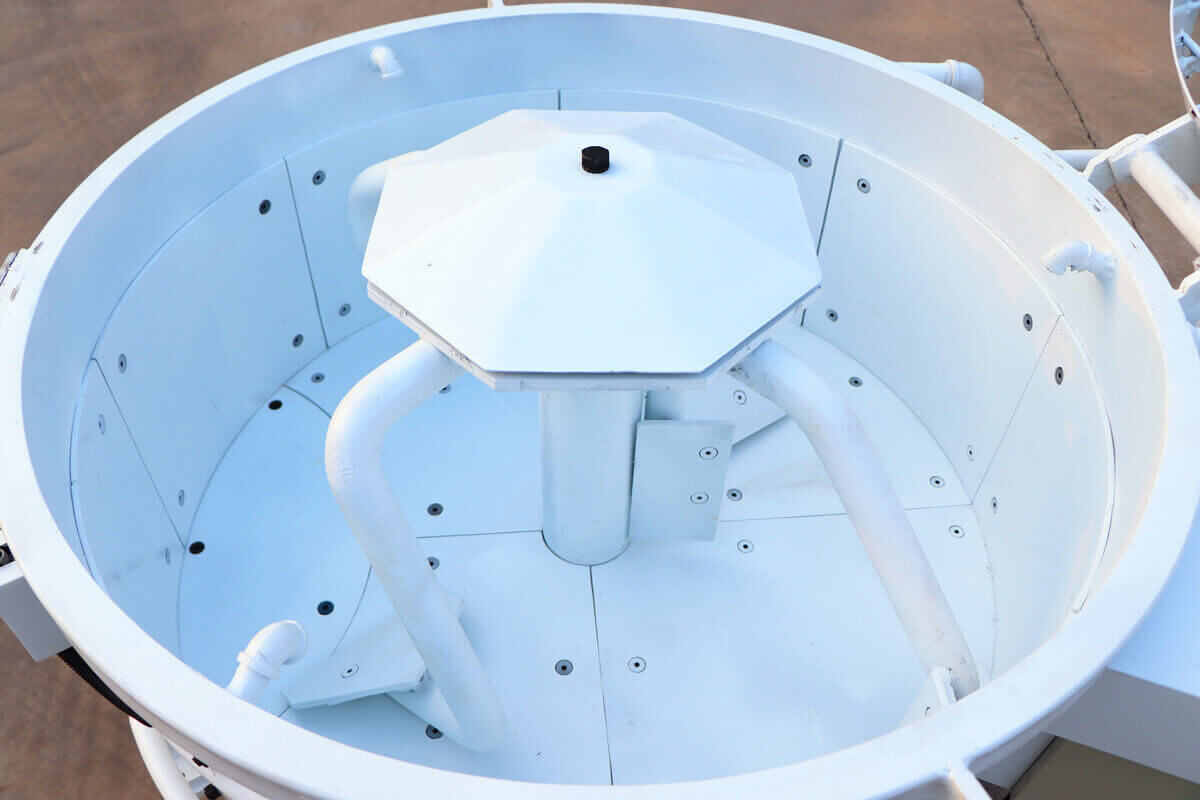

It is lined with polypropylene plates or stainless steel plates, and has the advantages of being non-sticky, wear-resistant, compact, easy to operate, uniformly mixed, and easy to unload and transport.

It is lined with polypropylene plates or stainless steel plates, and has the advantages of being non-sticky, wear-resistant, compact, easy to operate, uniformly mixed, and easy to unload and transport.

LRM100 100kg refractory castable mixer factory display pictures:

Application

LRM100 100kg refractory castable mixer is suitable for mixing a variety of refractory materials.

It could work together with refractory wet shotcrete machine, used for refractory materials spraying project in the steel industry, including but not limited to:

1. Refractory castable mixer for mixing of various refractory bricks, refractory castables, refractory mud and other raw materials.

2. Refractory castable mixer for mixing of refractory materials used in construction, metallurgy, chemical industry and other industries.

3. Refractory castable mixer for mixing process on refractory production line.

It could work together with refractory wet shotcrete machine, used for refractory materials spraying project in the steel industry, including but not limited to:

1. Refractory castable mixer for mixing of various refractory bricks, refractory castables, refractory mud and other raw materials.

2. Refractory castable mixer for mixing of refractory materials used in construction, metallurgy, chemical industry and other industries.

3. Refractory castable mixer for mixing process on refractory production line.

Features

LRM100 100kg refractory castable mixer is a specialized piece of equipment designed for the efficient mixing of refractory materials, which are typically used in high-temperature applications such as in furnaces, kilns, and other industrial heating equipment.

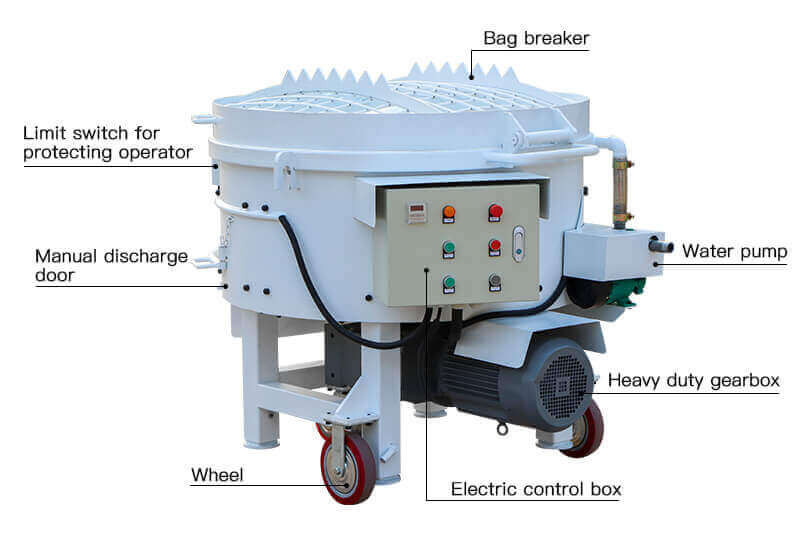

1. Pan mixer: This type of refractory castable mixer uses a pan-shaped container with a blade or paddle mechanism to mix the materials. The pan design ensures that all components are thoroughly combined without dead spots.

2. Special designed for site operation: It is built for on-site use, making it suitable for construction sites where refractory materials need to be mixed quickly and efficiently before installation.

3. Fast mixing speed and homogenous: The mixer is capable of achieving a high mixing speed while ensuring the materials are well-blended, producing a uniform mixture that is essential for the integrity of the refractory structures.

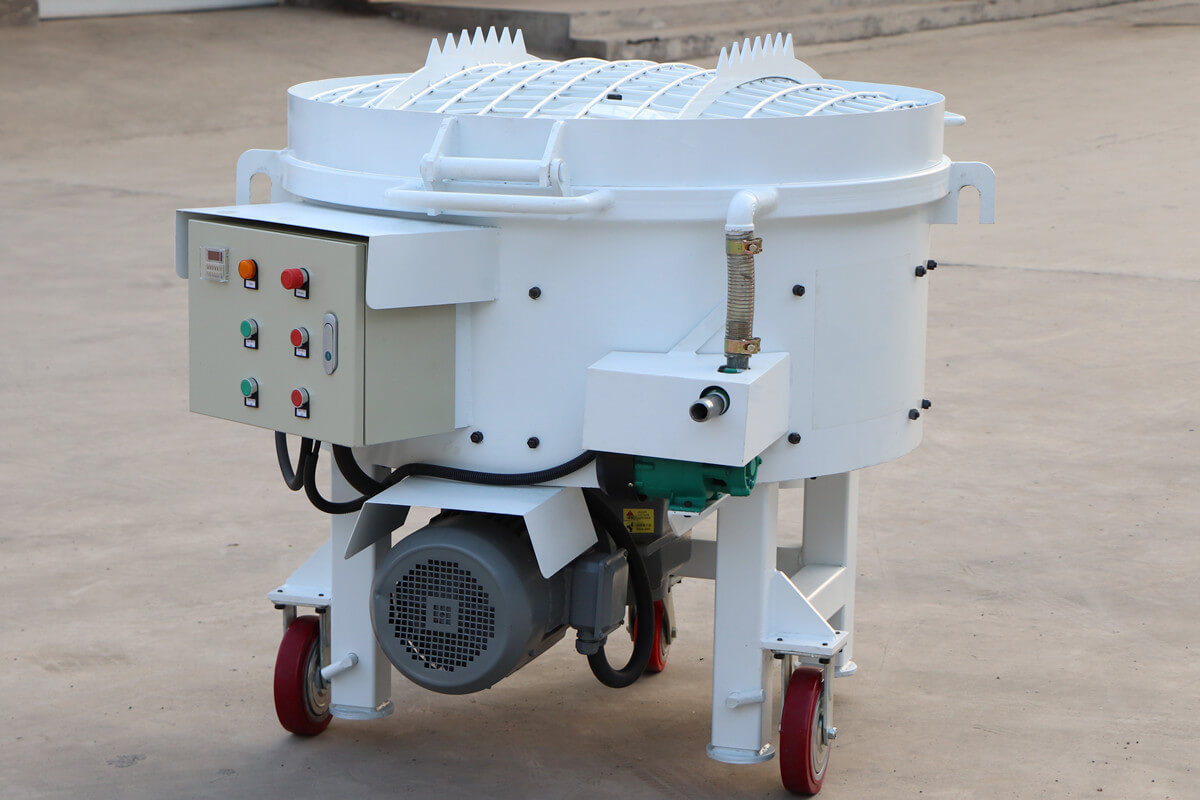

4. Compact structure: Its compact design makes it easy to maneuver and store on busy construction sites where space might be limited.

5. Comfortable feeding height: The castable refractory mixer is designed with an optimal feeding height, allowing operators to add ingredients easily without having to bend over excessively, reducing strain and increasing efficiency.

6. Easy to move: The mixer is likely equipped with wheels or a handle, making it simple to relocate as needed around the work area.

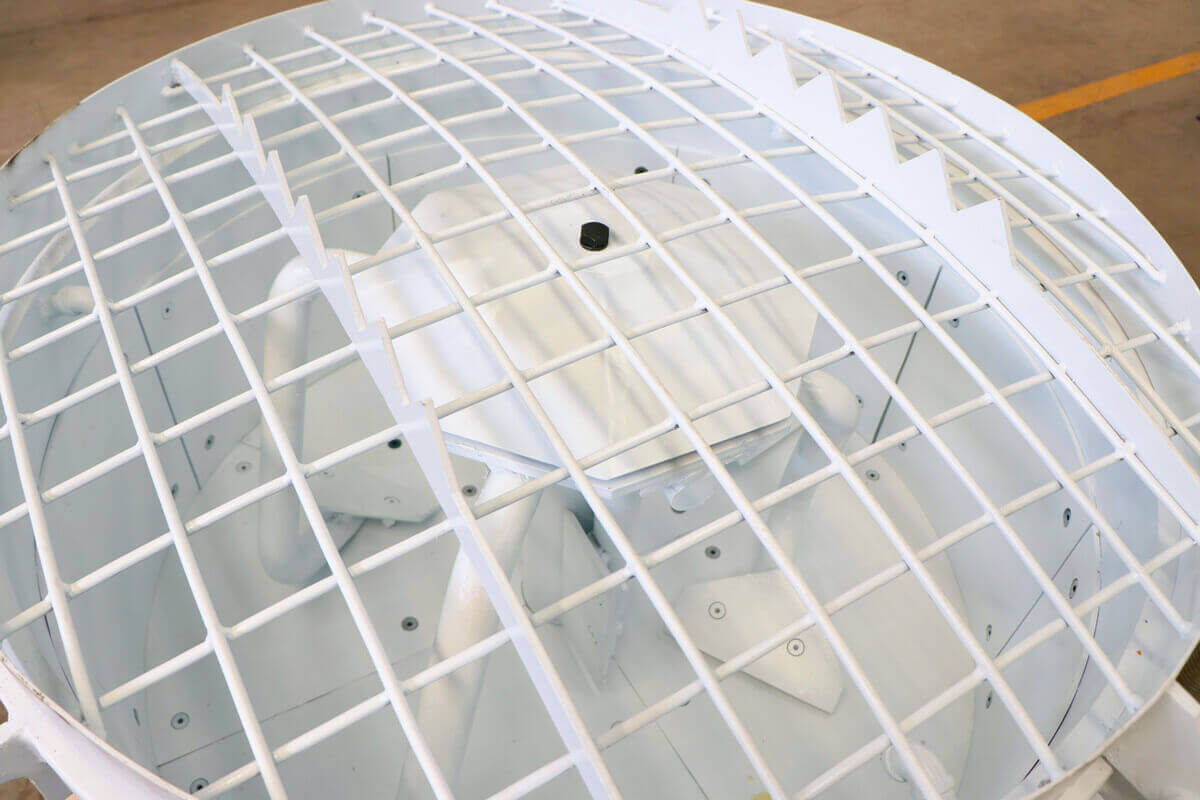

7. With bag breaker: A bag breaker feature helps to open and empty bags of dry ingredients into the mixer without creating dust clouds or spilling material, improving safety and cleanliness.

8. Water spray nozzles: These allow for precise control of water addition during the mixing process, which is crucial for achieving the right consistency in the refractory mix.

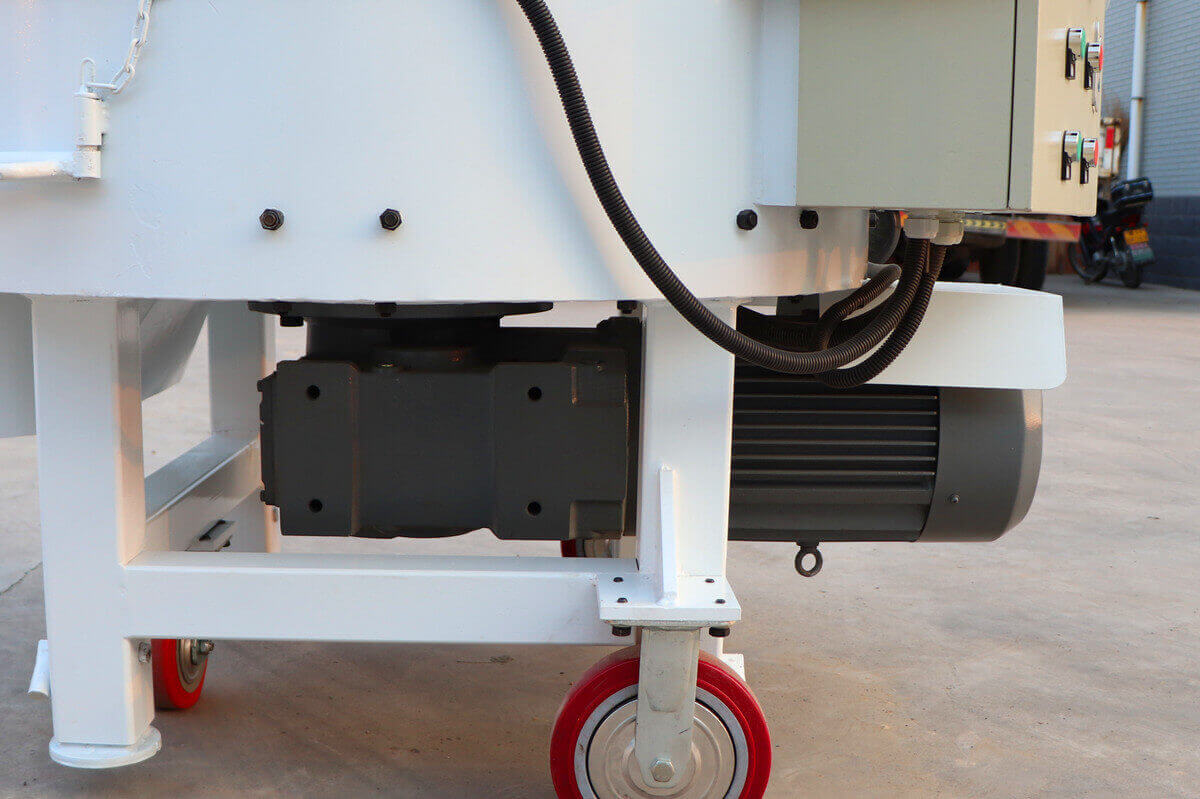

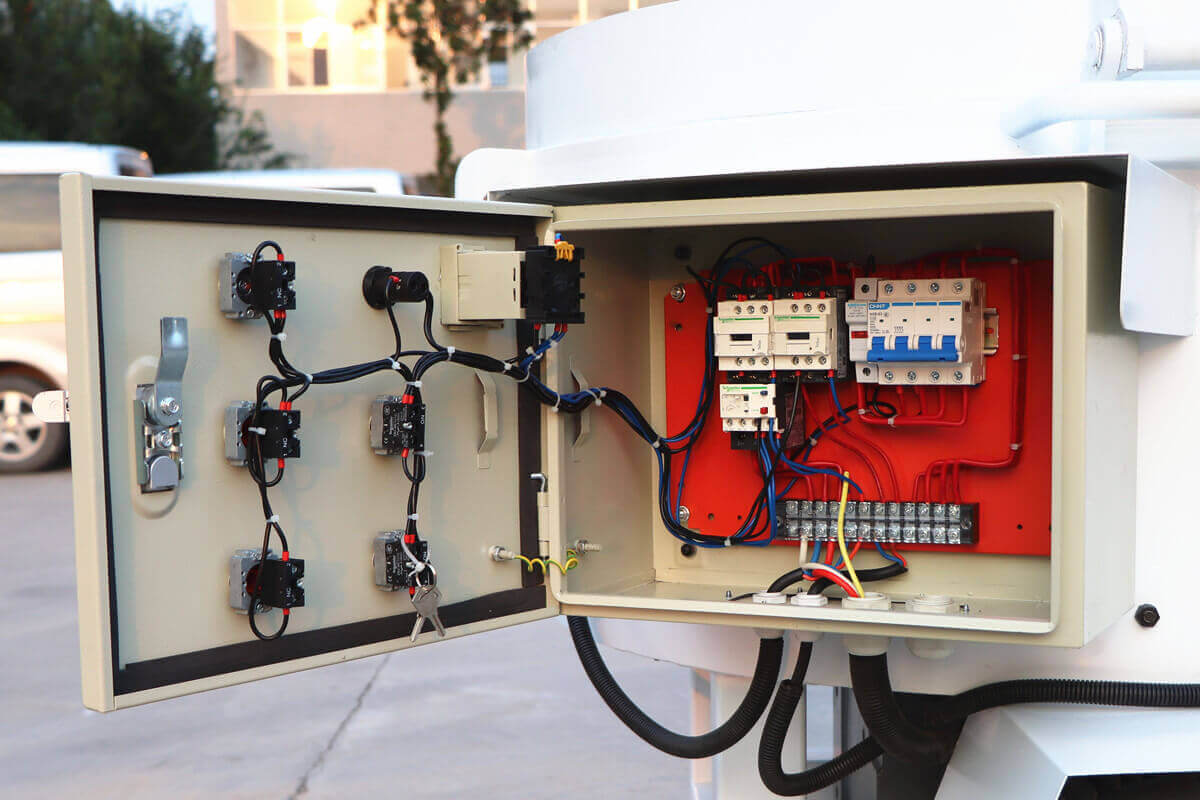

9. Low maintenance cost: The design incorporates features that reduce the need for frequent maintenance, saving time and money over the long term.

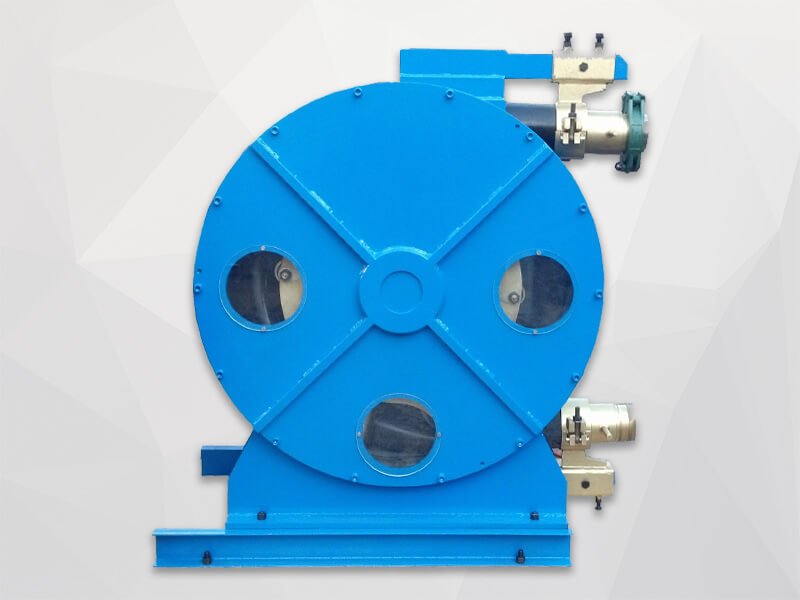

High wear-resistant steel liner in the mixer bottom and inner wall:

Features of LRM100 refractory mixer:

1. Pan mixer: This type of refractory castable mixer uses a pan-shaped container with a blade or paddle mechanism to mix the materials. The pan design ensures that all components are thoroughly combined without dead spots.

2. Special designed for site operation: It is built for on-site use, making it suitable for construction sites where refractory materials need to be mixed quickly and efficiently before installation.

3. Fast mixing speed and homogenous: The mixer is capable of achieving a high mixing speed while ensuring the materials are well-blended, producing a uniform mixture that is essential for the integrity of the refractory structures.

4. Compact structure: Its compact design makes it easy to maneuver and store on busy construction sites where space might be limited.

5. Comfortable feeding height: The castable refractory mixer is designed with an optimal feeding height, allowing operators to add ingredients easily without having to bend over excessively, reducing strain and increasing efficiency.

6. Easy to move: The mixer is likely equipped with wheels or a handle, making it simple to relocate as needed around the work area.

7. With bag breaker: A bag breaker feature helps to open and empty bags of dry ingredients into the mixer without creating dust clouds or spilling material, improving safety and cleanliness.

8. Water spray nozzles: These allow for precise control of water addition during the mixing process, which is crucial for achieving the right consistency in the refractory mix.

9. Low maintenance cost: The design incorporates features that reduce the need for frequent maintenance, saving time and money over the long term.

High wear-resistant steel liner in the mixer bottom and inner wall:

Product Details

Technical Parameters

Technical Data

| Item | LRM100 100kg refractory castable mixer |

| Mixing capacity | 100kg |

| Rotating speed | 33rpm |

| Motor Power | 4kw |

| Feeding Height | 1100mm |

| Dimensions | 1.4*1.3*1.1m |

| Weight | 550kg |

| Note:Technical data may change due to technical progress,subject to modification without notice. | |

LRM100 100kg refractory castable mixer packing and delivery:

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LRM1000 refractory pan mixer is a refractory pan mixer supplier Lead Equipment Co., Ltd. which is specially designed for mixing refractory materials, castables, etc.LRM1000 1000kg Mixing Capacity Refractory Pan Mixer

LRM1000 refractory pan mixer is a refractory pan mixer supplier Lead Equipment Co., Ltd. which is specially designed for mixing refractory materials, castables, etc.LRM1000 1000kg Mixing Capacity Refractory Pan Mixer -

LRM800 refractory mixer machine for sale is the most efficient and productive mixer for refractory castables. It is reinforced with bolt in high wear resistance steel drum liners, making the refractory pan mixer the most durable refractory mixers on the market.LRM800 Refractory Mixer Machine For Sale

LRM800 refractory mixer machine for sale is the most efficient and productive mixer for refractory castables. It is reinforced with bolt in high wear resistance steel drum liners, making the refractory pan mixer the most durable refractory mixers on the market.LRM800 Refractory Mixer Machine For Sale -

LZ-5AR refractory spraying machine is driven by one air motor (also it could be driven by a electrical motor). LZ-5AR is a powerful, compact and reliable refractory material spraying machine, it is specifically designed for refractory dry mix shotcrete application, as well as for concrete shotcrete application.LZ-5AR Refractory spraying machine

LZ-5AR refractory spraying machine is driven by one air motor (also it could be driven by a electrical motor). LZ-5AR is a powerful, compact and reliable refractory material spraying machine, it is specifically designed for refractory dry mix shotcrete application, as well as for concrete shotcrete application.LZ-5AR Refractory spraying machine -

LZ-5ER gunning machine for refractory for sale is a dry gunning machine designed for dry spraying refractory materials. It usually contains additives that make it more sticky.LZ-5ER Gunning Machine for Refractory

LZ-5ER gunning machine for refractory for sale is a dry gunning machine designed for dry spraying refractory materials. It usually contains additives that make it more sticky.LZ-5ER Gunning Machine for Refractory

.jpg)

.jpg)

.jpg)