Your position:

Home > Products > Refractory Gunning Machine

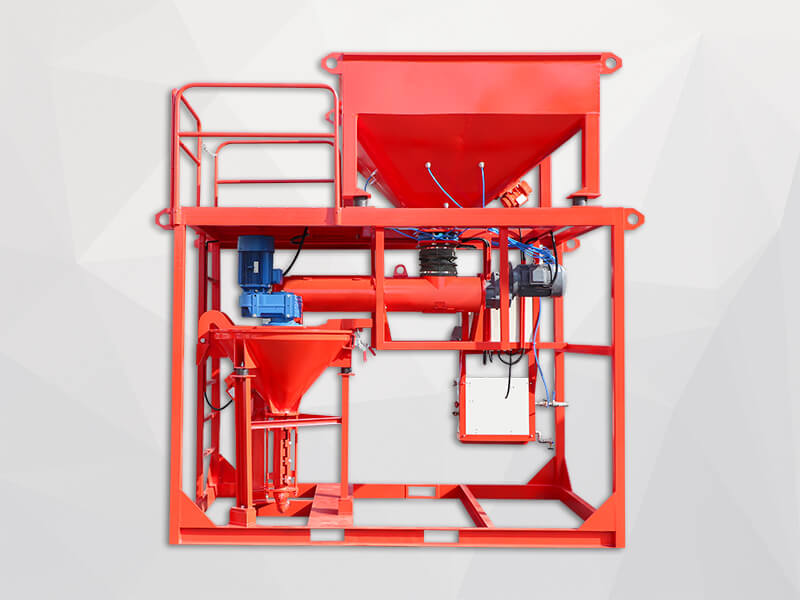

LTS-40E/S Tundish spraying machine for sale

In the metallurgical industry, especially in the continuous casting process, tundish spraying machine is used for spraying refractory mass in tundishes, tundish is a container used to receive molten steel poured from the ladle and distribute it to various crystallizers. It plays the role of buffering, distributing and further purifying the molten steel.

1.5m³

5.5Kw

40L/min

7.5Kw

40L/min

6mm

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

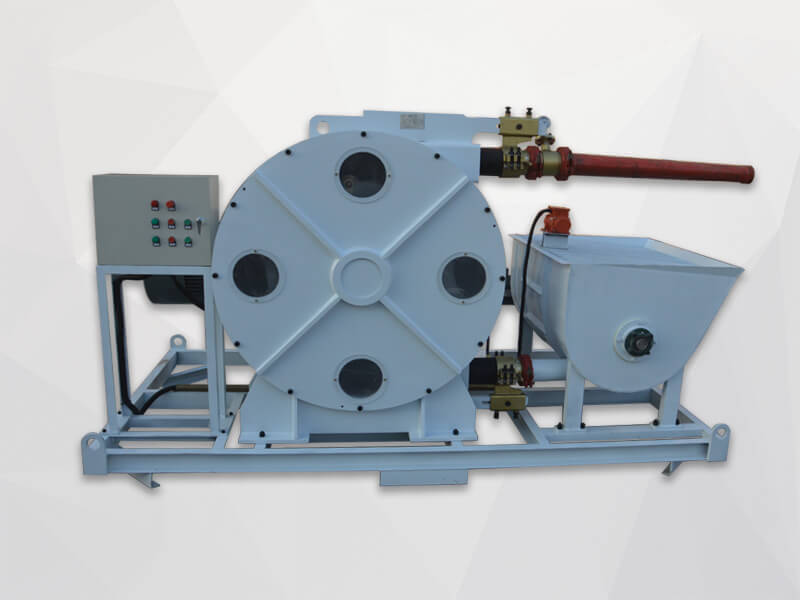

The LTS-40E/S Tundish spraying machine represents an advanced integration of a mixing station, pumping mechanism, and application nozzle designed specifically for the application of refractory slurries during the maintenance of tundishes in steel production facilities.

This system's architecture, which pairs a Ø250 continuous mixer with a vertical screw pump model 2L7, ensures the creation of a uniform blend of premium refractory compounds. This results in optimal and cost-effective lining of tundishes, which is critical for maintaining seamless operations in steel mills equipped with continuous casting technologies.

Operation Mechanism of LTS-40E/S Tundish spraying machine for sale:

Dry, pre-blended slurry mixes are introduced from bulk containers into a storage bin. A fluidizing component paired with a vibrator facilitates a reliable stream of dry ingredients and ensures smooth loading into the continuous mixer. Within this mixer, the dry components encounter a regulated influx of water, transforming into a consistent, high-grade sprayable slurry.

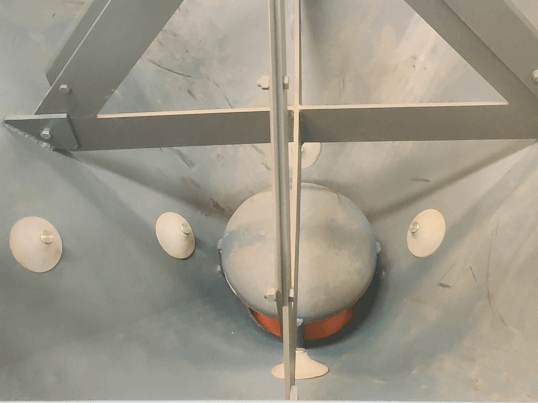

Once prepared, the wet mixture transfers from the continuous mixer to the wet mortar reservoir attached to the screw pump. The design of this reservoir features a funnel geometry along with a centrally aligned pump actuator. A vibrator and transport shaft within the wet mortar container work in tandem to maintain a steady and obstruction-free passage of the slurry towards the intake of the vertically oriented screw pump.

Through pressure-resistant conduits, the screw pump delivers the refractory material to a spray applicator, where it can be applied either by hand or through automated means. This process ensures that the refractory coating is deposited evenly on the interior surfaces of the tundish without waste. The precision of the spraying is managed via the nozzle at the end of the spray apparatus.

This system's architecture, which pairs a Ø250 continuous mixer with a vertical screw pump model 2L7, ensures the creation of a uniform blend of premium refractory compounds. This results in optimal and cost-effective lining of tundishes, which is critical for maintaining seamless operations in steel mills equipped with continuous casting technologies.

Operation Mechanism of LTS-40E/S Tundish spraying machine for sale:

Dry, pre-blended slurry mixes are introduced from bulk containers into a storage bin. A fluidizing component paired with a vibrator facilitates a reliable stream of dry ingredients and ensures smooth loading into the continuous mixer. Within this mixer, the dry components encounter a regulated influx of water, transforming into a consistent, high-grade sprayable slurry.

Once prepared, the wet mixture transfers from the continuous mixer to the wet mortar reservoir attached to the screw pump. The design of this reservoir features a funnel geometry along with a centrally aligned pump actuator. A vibrator and transport shaft within the wet mortar container work in tandem to maintain a steady and obstruction-free passage of the slurry towards the intake of the vertically oriented screw pump.

Through pressure-resistant conduits, the screw pump delivers the refractory material to a spray applicator, where it can be applied either by hand or through automated means. This process ensures that the refractory coating is deposited evenly on the interior surfaces of the tundish without waste. The precision of the spraying is managed via the nozzle at the end of the spray apparatus.

Application

The specific application of LTS-40E/S Tundish spraying machine is mainly concentrated in the continuous casting process of the steel industry, used to repair and maintain the lining of the tundish. In the continuous casting process, the tundish is a transition container between the molten steel from the steelmaking furnace to the casting mold. The condition of the refractory material inside it has an important impact on the stability of the production process and the quality of the castings. When the tundish needs to be repaired or the lining is replaced, the Tundish Spraying Machine can efficiently spray a new layer of refractory material to ensure that it has good thermal insulation performance and sufficient wear resistance.

Features and Advantages

LTS-40E/S Tundish spraying machine features:

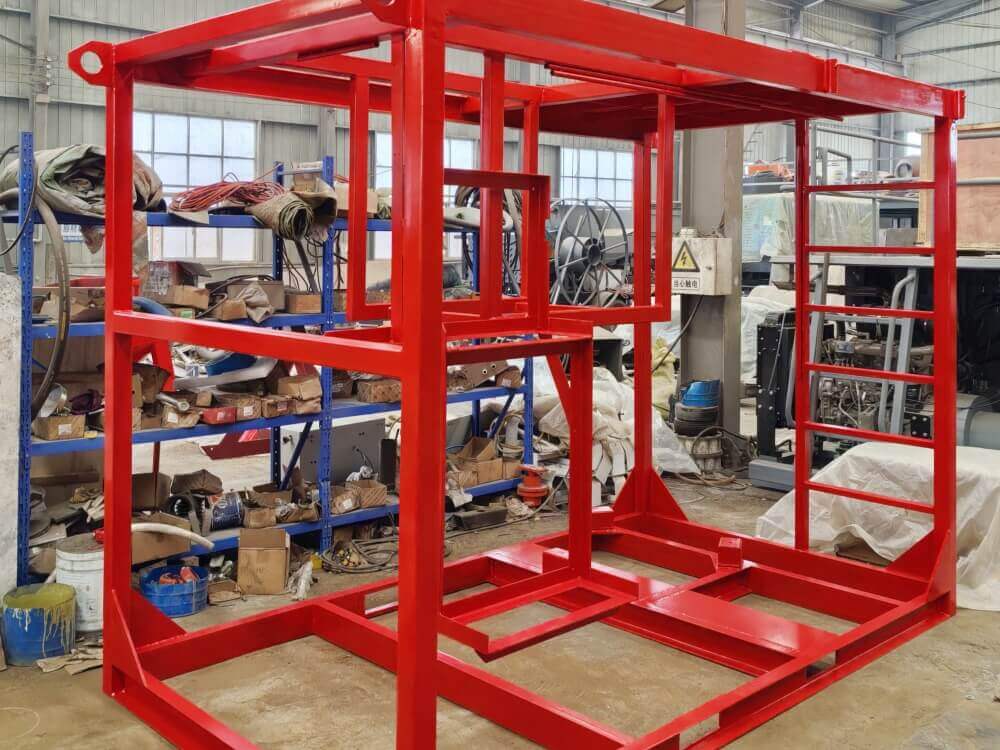

1. Frame

A steel frame with ladder, platform and rails detachable for transport herein included

2. 1500L Hopper

Dry mortar hopper with BIG-BAG-cutter detachable for transport

BIG-BAG cutter

Fluidifying system on dry mortar silo with compressed air control

OLI Vibrator for dry mortar refractory hopper

3. Continuous Mixer

Transferring and stirring 2 parts

The mixing blade is made of wear-resistant steel and, which can easily replace the blade.

GEKA quick connector (water filling port)

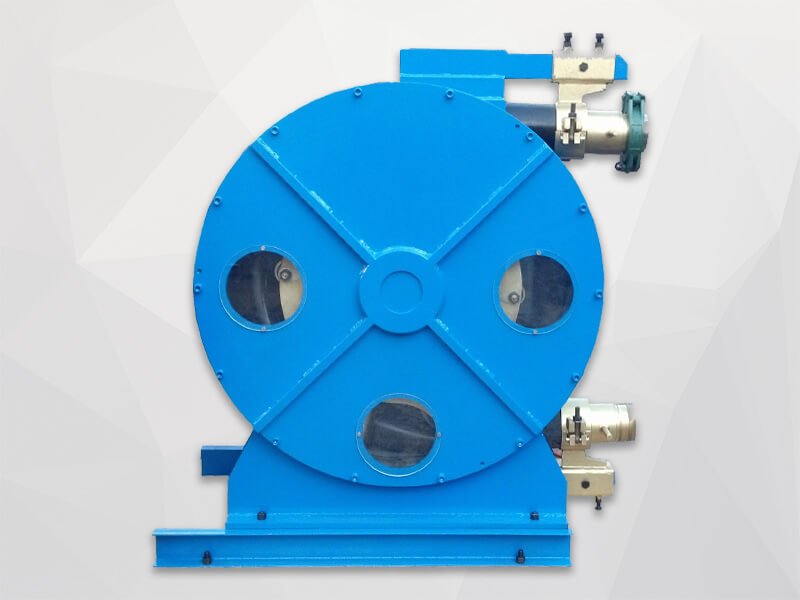

4. Pump Unit

Hopper with vibrator

Vertical mortar screw pump

Germany imports stator and rotor

Level probe for wet mortar refractory hopper (Optional part)

5. Control System (safe, and easy to operate)

6. Water and Air Armature

Air control

Water control: for continuous mixer

7. 350L Water Tank (optional part)

304 stainless steel water tank

A heating and pressurization system

GEKA quick connector

LTS-40E/S Tundish spraying machine advantages:

1. Fast and easy cleaning of all machine parts that have been in contact with wet mortar refractory;

2. Long lifetime by adjustable pressure and in case of wear adjustable screw pump;

3. Few wearing parts and low wear because of the use of high quality materials;

4. Always homogenous mix by steadily working continuous mixer;

5. Adjustable, controlled water-material proportion;

6. Joint free, monolithic coating of Tundish linings;

7. Constant conveying of wet material;

8. No dust rising during spraying;

9. Safe and easy working conditions.

1. Frame

A steel frame with ladder, platform and rails detachable for transport herein included

2. 1500L Hopper

Dry mortar hopper with BIG-BAG-cutter detachable for transport

BIG-BAG cutter

Fluidifying system on dry mortar silo with compressed air control

OLI Vibrator for dry mortar refractory hopper

3. Continuous Mixer

Transferring and stirring 2 parts

The mixing blade is made of wear-resistant steel and, which can easily replace the blade.

GEKA quick connector (water filling port)

4. Pump Unit

Hopper with vibrator

Vertical mortar screw pump

Germany imports stator and rotor

Level probe for wet mortar refractory hopper (Optional part)

5. Control System (safe, and easy to operate)

6. Water and Air Armature

Air control

Water control: for continuous mixer

7. 350L Water Tank (optional part)

304 stainless steel water tank

A heating and pressurization system

GEKA quick connector

LTS-40E/S Tundish spraying machine advantages:

1. Fast and easy cleaning of all machine parts that have been in contact with wet mortar refractory;

2. Long lifetime by adjustable pressure and in case of wear adjustable screw pump;

3. Few wearing parts and low wear because of the use of high quality materials;

4. Always homogenous mix by steadily working continuous mixer;

5. Adjustable, controlled water-material proportion;

6. Joint free, monolithic coating of Tundish linings;

7. Constant conveying of wet material;

8. No dust rising during spraying;

9. Safe and easy working conditions.

Product Details

Technical Parameters

Technical Data

| Model | LTS-40E/S Tundish spraying machine |

| Useful volume of the hopper | 1.5m³ |

| Mixer motor | 5.5Kw |

| Mixing output | 40L/min |

| Pump motor | 7.5Kw |

| Pump output | 40 L/min |

| Conveying pressure | 20bar, Max. 40 bar |

| Conveying distance, horizontally | Max. 40m |

| Conveying height | Max. 20m |

| Max. aggregate size | 6mm |

| Hose connection to the pump | ID32 |

| Required water connection | ID25/3bar |

| Required air connection | ID25/6bar |

| Required compressed air | 300 L/min for spraying |

| Operating voltage | 380V,50Hz 3phase, customized voltage |

| Overall dimension | 3000(L)×1780(W)×3250(H)mm |

| Weight | 1635Kg |

| Note: 1. All data are tested by water. 2. We can customize tundish spraying machines according to your requirements. |

|

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LZ-3ER/SC Piccola rotary refractory gunning machine is widely used in the repair of kiln linings in the steel, cement, glass and other industries. Its precise output and efficient sealing design ensure uniform coverage of refractory materials and extend the service life of the kiln.LZ-3ER/SC Piccola rotary refractory gunning machine

LZ-3ER/SC Piccola rotary refractory gunning machine is widely used in the repair of kiln linings in the steel, cement, glass and other industries. Its precise output and efficient sealing design ensure uniform coverage of refractory materials and extend the service life of the kiln.LZ-3ER/SC Piccola rotary refractory gunning machine -

LZ-3ER Refractory Gunite Machine is suitable for spraying and repairing a variety of refractory materials, including refractory bricks, refractory concrete, refractory coatings, etc., to meet the needs of different equipment.LZ-3ER Refractory Gunite Machine

LZ-3ER Refractory Gunite Machine is suitable for spraying and repairing a variety of refractory materials, including refractory bricks, refractory concrete, refractory coatings, etc., to meet the needs of different equipment.LZ-3ER Refractory Gunite Machine -

LZ-5AR refractory spraying machine is driven by one air motor (also it could be driven by a electrical motor). LZ-5AR is a powerful, compact and reliable refractory material spraying machine, it is specifically designed for refractory dry mix shotcrete application, as well as for concrete shotcrete application.LZ-5AR Refractory spraying machine

LZ-5AR refractory spraying machine is driven by one air motor (also it could be driven by a electrical motor). LZ-5AR is a powerful, compact and reliable refractory material spraying machine, it is specifically designed for refractory dry mix shotcrete application, as well as for concrete shotcrete application.LZ-5AR Refractory spraying machine -

A refractory mixing and pressure conveying unit is a critical system in industries that deal with high-temperature processes. It is designed to mix refractory materials—substances resistant to heat—and transport them pneumatically to the required application sites, such as the linings of furnaces, kilns, incinerators, and reactors.LDPX Pneumatic refractory mixing and pressure conveying unit

A refractory mixing and pressure conveying unit is a critical system in industries that deal with high-temperature processes. It is designed to mix refractory materials—substances resistant to heat—and transport them pneumatically to the required application sites, such as the linings of furnaces, kilns, incinerators, and reactors.LDPX Pneumatic refractory mixing and pressure conveying unit

.jpg)

.jpg)