Your position:

Home > Products > Refractory Gunning Machine

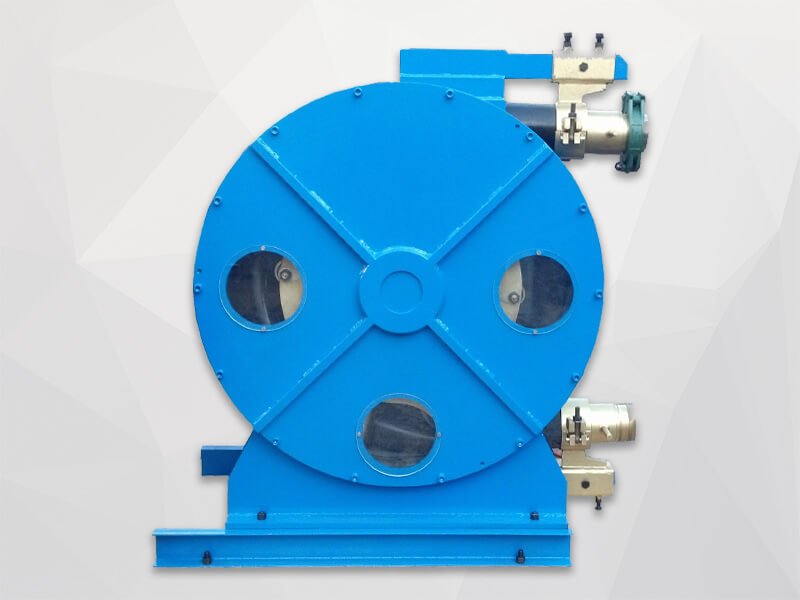

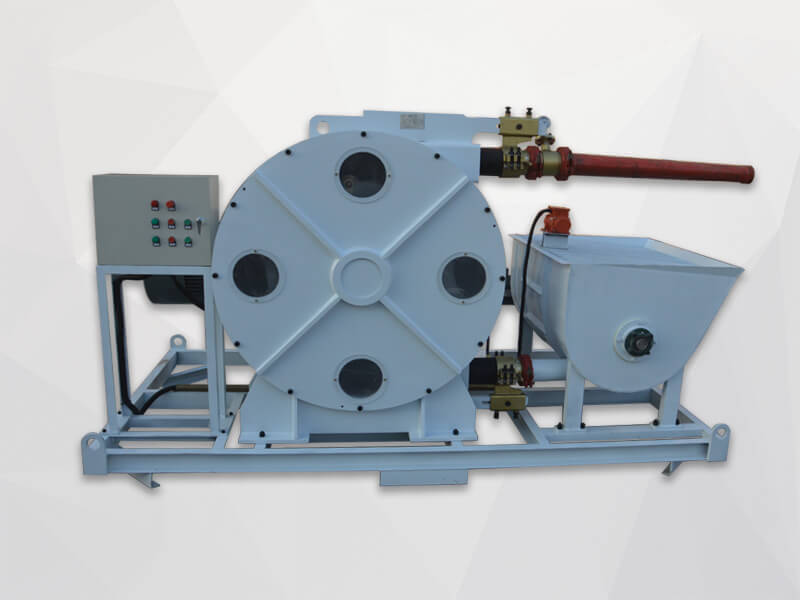

LZ-1.5ER Refractory gunning machine for furnace kiln

LZ-1.5ER refractory gunning machine for furnace kiln can be used for spray refractory materials for refractory gunite jobsite such as lining kilns, boilers, furnaces.

LZ-1.5ER

10mm

0.7~3m3/h

0.2~0.4Mpa (29-58PSI)

32/38mm

5~6m3/min(180-215CFM)

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

LZ-1.5ER Refractory gunning machine for sale is a continuous rotor shotcrete machine, which has been widely used in the refractory material industry. This gunning machine can be used in places with high requirements for dust-free and low-wear gunning of dry refractory concrete.

We are a professional refractory gunning machine for furnace kiln manufacturer. We have now developed pnumatic refractory gunning machine and electric motor refractory gunning machine for option. If you are interested in our high-quality refractory gunning machine, please leave us a message and we will help you as soon as possible.

The working principle of refractory gunning machine for furnace kiln:

LZ-1.5ER is straight chamber rotor type refractory gunning machine. The gunning material can enter the rotor through a hopper and a star agitator, and then the rotor is driven by a rotating current or a compressed air motor to deliver the gunning material to the blow-out hole, where the gunning material is blown into the hose or through compressed air at the blow-out hole pipeline. The dry or slightly moist spray material will be mixed with water in a nozzle mixing unit before being discharged from the pipe. Then the refractory gunning machine starts to spray the refractory material in the furnace kiln.

Rotor system could change different size rotor body, achieve different output capacity from 0.7m3/h to 3m3/h.

A complete set of refractory gunning machine is including new type pre-dampening nozzle assy, high pressure water pump, conveying hose, water hose, joint and clamp etc.

★ Variable output with ABB variable-frequency drive.

★ Bag cutter and high hopper with vibrator.

★ Coupling and clamps are optional as below.

★ Premium grade blast hose used as conveying hose.

★ Heavy-duty solid wheels, easy to move in harsh.

★ Portable refractory gunning machine is equipped with collect dust system, environmentally friendly.

Customized variable output refractory gunning machine is equipped with new pre-dampening nozzle for refractory materials and castable, which has the below advantages:

Customized variable output refractory gunning machine is equipped with new pre-dampening nozzle for refractory materials and castable, which has the below advantages:

1. Low rebound, low dust;

2. Reduce additive water amount;

3. Improve refractory compactness and strength.

We are a professional refractory gunning machine for furnace kiln manufacturer. We have now developed pnumatic refractory gunning machine and electric motor refractory gunning machine for option. If you are interested in our high-quality refractory gunning machine, please leave us a message and we will help you as soon as possible.

The working principle of refractory gunning machine for furnace kiln:

LZ-1.5ER is straight chamber rotor type refractory gunning machine. The gunning material can enter the rotor through a hopper and a star agitator, and then the rotor is driven by a rotating current or a compressed air motor to deliver the gunning material to the blow-out hole, where the gunning material is blown into the hose or through compressed air at the blow-out hole pipeline. The dry or slightly moist spray material will be mixed with water in a nozzle mixing unit before being discharged from the pipe. Then the refractory gunning machine starts to spray the refractory material in the furnace kiln.

Rotor system could change different size rotor body, achieve different output capacity from 0.7m3/h to 3m3/h.

A complete set of refractory gunning machine is including new type pre-dampening nozzle assy, high pressure water pump, conveying hose, water hose, joint and clamp etc.

★ Variable output with ABB variable-frequency drive.

★ Bag cutter and high hopper with vibrator.

★ Coupling and clamps are optional as below.

★ Premium grade blast hose used as conveying hose.

★ Heavy-duty solid wheels, easy to move in harsh.

★ Portable refractory gunning machine is equipped with collect dust system, environmentally friendly.

1. Low rebound, low dust;

2. Reduce additive water amount;

3. Improve refractory compactness and strength.

Application

LZ-1.5ER Refractory gunning machines are widely used in metallurgy, industrial furnaces and steel mills.

Features

1. The refractory gunning machine for furnace kiln has the functions of mixing, conveying, and spraying.

2. Refractory gunning machine for furnace kiln has good injection quality and fast construction speed, which greatly saves labor.

3. With this refractory gunning machine, you can get low dust and high performance spraying flow in nozzle.

4. Refractory gunning machine for furnace kiln is a shaped product with excellent quality and durability. And related vulnerable parts, rotating plate, coupling plate, spray gun, and other accessories are ready.

2. Refractory gunning machine for furnace kiln has good injection quality and fast construction speed, which greatly saves labor.

3. With this refractory gunning machine, you can get low dust and high performance spraying flow in nozzle.

4. Refractory gunning machine for furnace kiln is a shaped product with excellent quality and durability. And related vulnerable parts, rotating plate, coupling plate, spray gun, and other accessories are ready.

Product Details

Technical Parameters

Technical Data

| Model | LZ-1.5ER refractory gunning machine for furnace kiln |

| Output Capacity | 0.7~3m3/h |

| Max. Aggregate size | 10mm |

| Conveying Pressure | 0.2~0.4Mpa (29-58PSI) |

| Conveying Hose ID | 32/38mm |

| Air Consumption for conveying material | 5~6m3/min(180-215CFM) |

| Motor Power | 4Kw |

| Conveying Distance | 60m (Vertical) |

| Conveying Distance | 200m (Horizontal) |

| Material Charging Height | 1.16m |

| Rotor Speed | 7r/min, continuous spraying |

| Weight | 660Kg |

| Overall Dimension | 1600×840×1300mm |

| Note: Air motor full pneumatic refractory gunning machine for furnace kiln for option. | |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

Refractory gunning machine is a stereotyped product with good quality and durability. The wearing parts, rotating plate, bonding plate, spray gun and other accessories are adequately stocked.LZ-3ER/S Refractory gunning machine

Refractory gunning machine is a stereotyped product with good quality and durability. The wearing parts, rotating plate, bonding plate, spray gun and other accessories are adequately stocked.LZ-3ER/S Refractory gunning machine -

LZ-3AR refractory shotcrete machine for sale in China with air motor drive is specifically designed for refractory dry-mix shotcrete gunning applications. With thisLZ-3AR refractory shotcrete machine, you can get low dust, low bound and high performance spraying flow in nozzle.LZ-3AR Refractory Shotcrete Machine for Sale

LZ-3AR refractory shotcrete machine for sale in China with air motor drive is specifically designed for refractory dry-mix shotcrete gunning applications. With thisLZ-3AR refractory shotcrete machine, you can get low dust, low bound and high performance spraying flow in nozzle.LZ-3AR Refractory Shotcrete Machine for Sale -

LZ-5AR refractory spraying machine is driven by one air motor (also it could be driven by a electrical motor). LZ-5AR is a powerful, compact and reliable refractory material spraying machine, it is specifically designed for refractory dry mix shotcrete application, as well as for concrete shotcrete application.LZ-5AR Refractory spraying machine

LZ-5AR refractory spraying machine is driven by one air motor (also it could be driven by a electrical motor). LZ-5AR is a powerful, compact and reliable refractory material spraying machine, it is specifically designed for refractory dry mix shotcrete application, as well as for concrete shotcrete application.LZ-5AR Refractory spraying machine -

LRM refractory castable mixers are designed by refractory castable mixer manufacturer Lead Equipment for mixing refractory materials, castable materials, etc.LRM 100kg 250kg 500kg Refractory Castable Pan Mixer

LRM refractory castable mixers are designed by refractory castable mixer manufacturer Lead Equipment for mixing refractory materials, castable materials, etc.LRM 100kg 250kg 500kg Refractory Castable Pan Mixer

.jpg)

.jpg)

.jpg)