Your position:

Home > Products > Grout Mixing Plant

LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station

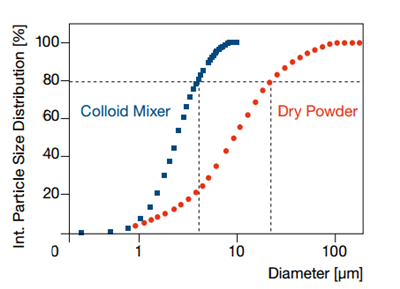

LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station is colloidal type, with high shear high speed, could mixing cement, mortar, water, bentonite etc.

300L

300L

300L

M ax 70L/min

Max 8Mpa

2800×1900×1650mm

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

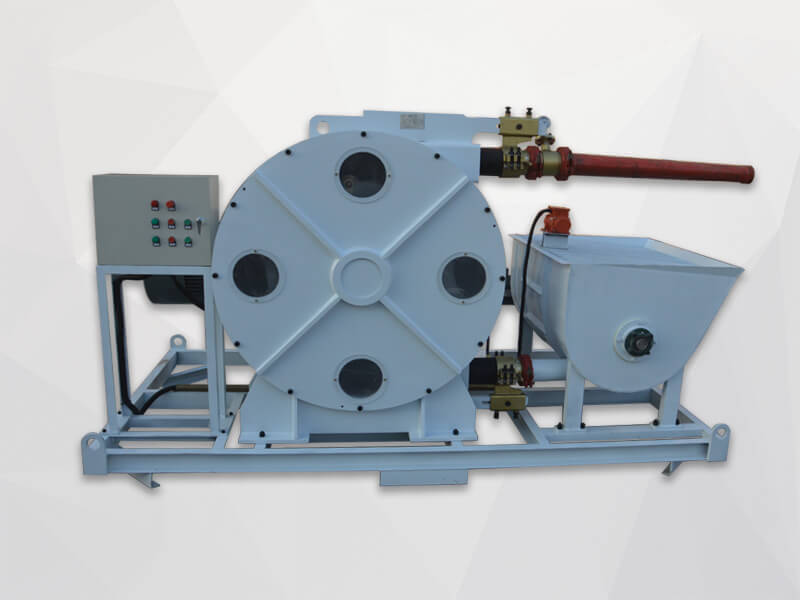

LGP3003003007080PI-E Cement slurry and mortar pumping station is a combination of mixer, agitator, mortar mechanical plunger type injection pump in one plant, it is suitable for making cement mixture and mortar cement mixture.

LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station is mainly used for ground/underground construction , such as highways, railways, water and electricity, construction, mining etc.

For the LGP300/300/300/70/80PI-E electric engine drive cement slurry and mortar pumping station, It with 300L high shear high speed grout mixer volume, and it has 2 agitator, both volume is 300L. Grout pump adopts frequency control, so the flow is step-less adjustable, grout pressure is 0-8Mpa, grout flow is 0-70L/min, the mixer is one vortex mixer could make sure mix cement slurry evenly and more quickly.

Mortar pumping station working principle:

Evenly mixed slurry convey to No. 1 agitator. Add sand to No. 1 agitator and mix. Evenly mixed mortar cement mixture flows into No. 2 agitator through discharge outlet. Grouting pump sucks mixture from No. 2 agitator and finish the grouting, gunite and backfilling etc. project. Grouting, while the next round of mixing can be carried out, thus the grout station achieves continuous work.

LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station is mainly used for ground/underground construction , such as highways, railways, water and electricity, construction, mining etc.

For the LGP300/300/300/70/80PI-E electric engine drive cement slurry and mortar pumping station, It with 300L high shear high speed grout mixer volume, and it has 2 agitator, both volume is 300L. Grout pump adopts frequency control, so the flow is step-less adjustable, grout pressure is 0-8Mpa, grout flow is 0-70L/min, the mixer is one vortex mixer could make sure mix cement slurry evenly and more quickly.

Mortar pumping station working principle:

Evenly mixed slurry convey to No. 1 agitator. Add sand to No. 1 agitator and mix. Evenly mixed mortar cement mixture flows into No. 2 agitator through discharge outlet. Grouting pump sucks mixture from No. 2 agitator and finish the grouting, gunite and backfilling etc. project. Grouting, while the next round of mixing can be carried out, thus the grout station achieves continuous work.

Application

1. Cement slurry and mortar pumping station can be applied in engineering - underwater foundation, offshore platform, coast foundation grouting reinforcement;

2. Cement slurry and mortar pumping plant can be applied in civil engineering - dam, tunnel, subway, mine, soil nailing wall, curtain, anchor, cable trench and anchor grouting;

3. Cement slurry grout mixing pumping plant can be applied in mine application - roadway reinforcement, backfill, waterproof grouting;

4. Cement slurry grout pumping station can be applied in building structure - building and bridge repair, foundation reinforcement, slope support, soil compaction, rock grouting.

2. Cement slurry and mortar pumping plant can be applied in civil engineering - dam, tunnel, subway, mine, soil nailing wall, curtain, anchor, cable trench and anchor grouting;

3. Cement slurry grout mixing pumping plant can be applied in mine application - roadway reinforcement, backfill, waterproof grouting;

4. Cement slurry grout pumping station can be applied in building structure - building and bridge repair, foundation reinforcement, slope support, soil compaction, rock grouting.

Features

1. Continuous output with small pulse.

2. HMI interface, flow and pressure can be visualized.

3. High speed vortex mixer ensures mix quickly and evenly.

4. Flameproof electric cabinet, protection grade IP56.

5. ement slurry grout pumping station is with CE, ISO certification.

6. Grouting pressure, output of the cement slurry and mortar pumping station is stepless adjustable.

7. Cement slurry and mortar pumping station has simple structure, light weight, easy maintenance.

8. Cement slurry and mortar pumping plant is with less spare parts ensure low maintenance costs.

9. Mixer and agitator switch by using squeeze handle, it is safe, reliable and easy to operate.

2. HMI interface, flow and pressure can be visualized.

3. High speed vortex mixer ensures mix quickly and evenly.

4. Flameproof electric cabinet, protection grade IP56.

5. ement slurry grout pumping station is with CE, ISO certification.

6. Grouting pressure, output of the cement slurry and mortar pumping station is stepless adjustable.

7. Cement slurry and mortar pumping station has simple structure, light weight, easy maintenance.

8. Cement slurry and mortar pumping plant is with less spare parts ensure low maintenance costs.

9. Mixer and agitator switch by using squeeze handle, it is safe, reliable and easy to operate.

Product Details

Technical Parameters

Technical Data

| Name | Data | |

| Type | LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station | |

| Mixer | Capacity | 300L |

| W/C ratio | 0.5~1 | |

| Rate Rev. | 1450 rpm | |

| Power | 7.5Kw | |

| NO.1 Agitator | Capacity | 300L |

| Rate Rev. | 49 rpm | |

| Power | 2.2Kw | |

| NO.2 Agitator | Capacity | 300L |

| Rate Rev. | 36 rpm | |

| Power | 1.5Kw | |

| Pump | Type | Mortar Pump |

| Output | Max 70L/min | |

| Pressure | Max 8Mpa | |

| Power | 11Kw | |

| Power requirements | Voltage 3 Phase 380V,50Hz | |

| Dimension | 2800×1900×1650mm | |

| Weight | 1350Kg | |

case

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

Leadcrete Equipment is one leading diesel engine grout plant manufacturer and supplier from China, if you need our diesel engine grout plant, we would be happy to share price list and details for your reference.LGP400/700/80DPL-D Diesel engine grout plant for sale

Leadcrete Equipment is one leading diesel engine grout plant manufacturer and supplier from China, if you need our diesel engine grout plant, we would be happy to share price list and details for your reference.LGP400/700/80DPL-D Diesel engine grout plant for sale -

Zhengzhou Lead Equipment Co., Ltd. is a leading manufacturer of grout mixer and pump in China. Our LGP550/800/150/70DPL-E Grout pumping station system include many types, as well as an unique supplier with ISO 9001:2008, SGS and CE certificate in below products in China.LGP550/800/150/70DPL-E Grout pumping station system

Zhengzhou Lead Equipment Co., Ltd. is a leading manufacturer of grout mixer and pump in China. Our LGP550/800/150/70DPL-E Grout pumping station system include many types, as well as an unique supplier with ISO 9001:2008, SGS and CE certificate in below products in China.LGP550/800/150/70DPL-E Grout pumping station system -

LGP250/350/100DPI-D Grout plant for foundation and micropile is a double piston type, diesel power and hydraulic drive grout unit. It is powerful with compact structure, convenient operation, less space occupation. It is an updated machine, based on the existing grouting mixing plant, as well as, grout plant for foundation is a combination of mixer, agitator and grout pump in one base frame.LGP250/350/100DPI-D Grout plant for foundation and micropile

LGP250/350/100DPI-D Grout plant for foundation and micropile is a double piston type, diesel power and hydraulic drive grout unit. It is powerful with compact structure, convenient operation, less space occupation. It is an updated machine, based on the existing grouting mixing plant, as well as, grout plant for foundation is a combination of mixer, agitator and grout pump in one base frame.LGP250/350/100DPI-D Grout plant for foundation and micropile -

LGP400/80PL-E Grout mixing and injection plant is a combination of mixer and grout pump in one base frame. It is mainly used to be made bentonite slurry, cement slurry, etc., in the application highway, railway, hydropower, construction, mining and other ground and underground construction.LGP400/80PL-E Grout mixing and injection plant

LGP400/80PL-E Grout mixing and injection plant is a combination of mixer and grout pump in one base frame. It is mainly used to be made bentonite slurry, cement slurry, etc., in the application highway, railway, hydropower, construction, mining and other ground and underground construction.LGP400/80PL-E Grout mixing and injection plant

.jpg)

.jpg)