Your position:

Home > Products > Grout Mixing Plant

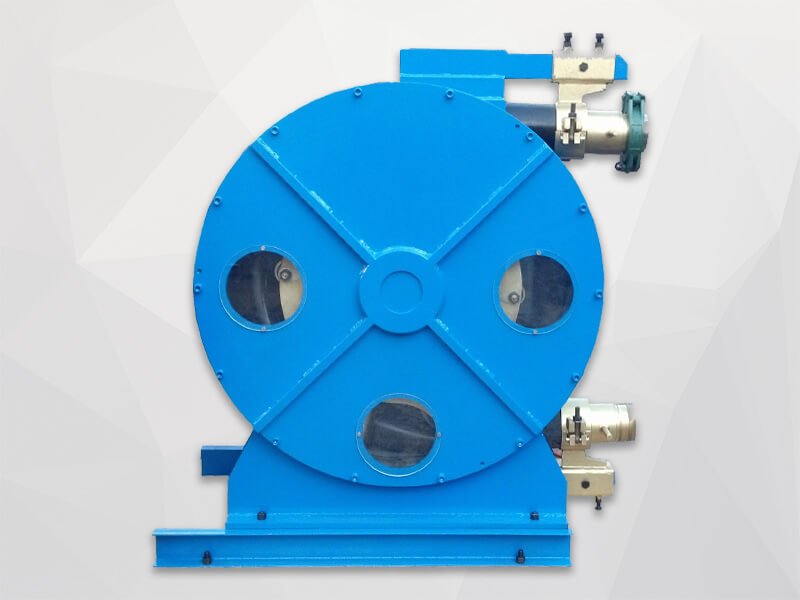

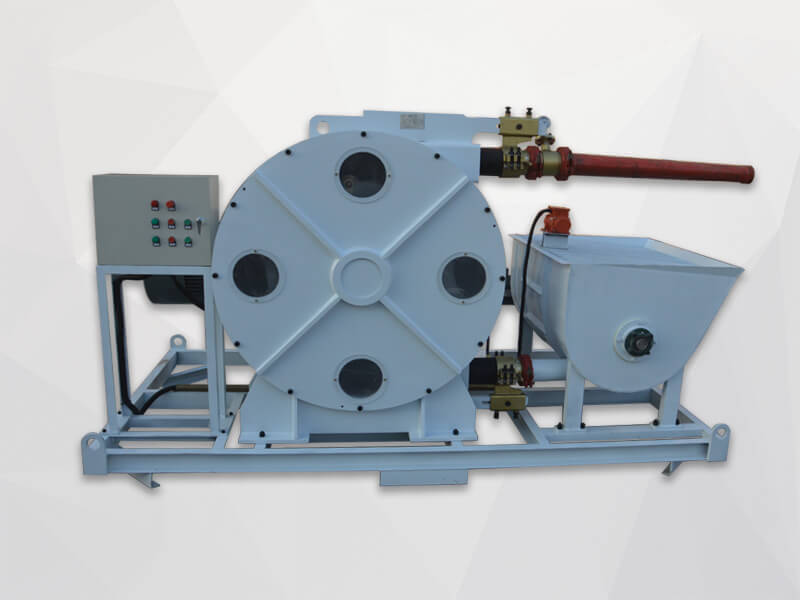

LGP300/350/85PL-E Grout pump and mixer

LGP300/350/85PL-E grout pump and mixer is a mixer, agitator and pump in one grout plant. Grout mixer and pump is mainly used in highway, railway, hydropower, construction, mining and other ground and underground construction. It includes a grout mixer tanks(300 liters), a grout agitator (350 liters) and a hydraulic plunger pump.

LGP300/350/85PL-E All in one grout plant

3 phase, 380V, 50HZ

2100x2030x1700mm

1250kg

300L

9kw

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

LGP300/350/85PL-E grout pump and mixer is a mixer, agitator and pump in one grout plant. LGP300/350/85PL-E grout mixer and pump is mainly used in highway, railway, hydropower, construction, mining and other ground and underground construction. It includes a grout mixer tanks(300 liters), a grout agitator (350 liters) and a hydraulic plunger pump.

LGP300/350/85PL-E grout machine pump and mixer is mainly suitable for mixing and pumping water, sand, cement, bentonite, filler, clay power, silicates and other additives.

High speed vortex mixer can ensure fast and uniform mixing. Quickly mix water, cement and other media into a uniform slurry. The mixed slurry is then transported to the agitator. The cement slurry pump is injected into the mixing bucket (tank). This ensures continuous mixing and grouting operations. The grouting pressure and displacement of the grouting pump are stepless and adjustable, and have fasteners that can greatly reduce the disassembly time for cleaning and maintenance. The operator control is located in the center and can be produced efficiently. Small size, easy to operate. It also takes up a small amount of space.

LGP300/350/85PL-E grout machine pump and mixer is mainly suitable for mixing and pumping water, sand, cement, bentonite, filler, clay power, silicates and other additives.

High speed vortex mixer can ensure fast and uniform mixing. Quickly mix water, cement and other media into a uniform slurry. The mixed slurry is then transported to the agitator. The cement slurry pump is injected into the mixing bucket (tank). This ensures continuous mixing and grouting operations. The grouting pressure and displacement of the grouting pump are stepless and adjustable, and have fasteners that can greatly reduce the disassembly time for cleaning and maintenance. The operator control is located in the center and can be produced efficiently. Small size, easy to operate. It also takes up a small amount of space.

Application

1. Civil engineering - grout pump and mixer can be used for dam, tunnel, subway, mine, soil nailing wall, curtain, anchor, cable trench and anchor grouting.

2. Mine application - roadway reinforcement, backfill, waterproof grouting.

3. Building structure - grout mixer and pump can be used for building and bridge repair, foundation reinforcement, slope support, soil compaction, terrg grouting.

4. Utilities – encasements, waterproofing, slope line grouting.

5. Geotechnical – all in one grout plant can be used for geothermal grouting, deep well casing, monitor wells, well sealing and abandonment.

6. Pipe jacking machine application - grout machine pump and mixer is acted as a grouting plant in the pipe jacking machine.

7. Marine – underwater foundations, piers, breakers, shoreline foundations.

2. Mine application - roadway reinforcement, backfill, waterproof grouting.

3. Building structure - grout mixer and pump can be used for building and bridge repair, foundation reinforcement, slope support, soil compaction, terrg grouting.

4. Utilities – encasements, waterproofing, slope line grouting.

5. Geotechnical – all in one grout plant can be used for geothermal grouting, deep well casing, monitor wells, well sealing and abandonment.

6. Pipe jacking machine application - grout machine pump and mixer is acted as a grouting plant in the pipe jacking machine.

7. Marine – underwater foundations, piers, breakers, shoreline foundations.

Features

1. All in one grout plant is combination of mixer, agitator and hydraulic grout pump in one base frame.

2. Siemens electric motor(WEG electric motor is optional).

3. Schneider component for electric control box.

4. Yuken reversing valve for hydraulic system of grout pump.

5. Butterfly valve of mixer and agitator.

6. Linked switch between mixer and agitator.

7. Oil temperature gauge of our grout pump and mixer can automatically control cooler fan working in normal temperature range, if temperature is too high, the machine will stop work automatically.

Product Details

Technical Parameters

Technical Data

| Type | LGP300/350/85PL-E Grout pump and mixer |

| Voltage | 3 phase, 380V, 50HZ |

| Dimensions | 2100x2030x1700mm |

| Weight | 1250kg |

| Mixer | |

| Capacity | 300L |

| Power | 9kw |

| Rated Rev. | 1500rpm |

| Agitator | |

| Volume | 350L |

| Power | 1.5kw |

| Rated Rev. | 36rpm |

| Pump | |

| Type | Hydraulic plunger pump |

| Pressure and Output | 24 Bar (low pressure) 85L/min |

| 50 Bar (high pressure) 55L/min | |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station -

LGP800/1200/200PI-D grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit

LGP800/1200/200PI-D grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit -

LGP350/800/70PI-E electric grout plant is a combination of grout pump, grout mixer with agitator in one base frame. The electric grout plant is mainly used to be made bentonite slurry, cement slurry etc.LGP350/800/70PI-E Electric Grout Plant

LGP350/800/70PI-E electric grout plant is a combination of grout pump, grout mixer with agitator in one base frame. The electric grout plant is mainly used to be made bentonite slurry, cement slurry etc.LGP350/800/70PI-E Electric Grout Plant -

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale

.jpg)

.jpg)