Your position:

Home > Products > Grout Mixing Plant

LGP250/700/75PI-E Grout Injection Station

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.

7.5KW

1100L/min

0-75L/min, 0-50bar

0-40L/min, 0-100bar

250L

700L

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

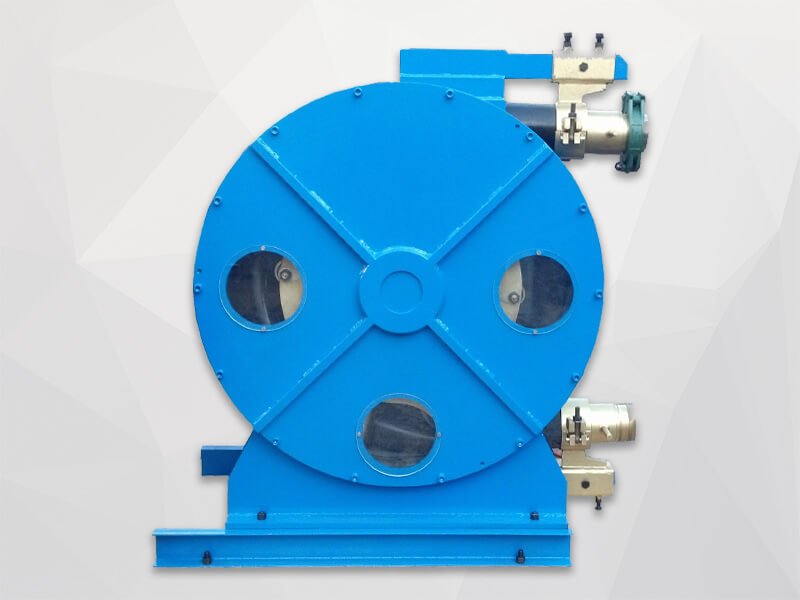

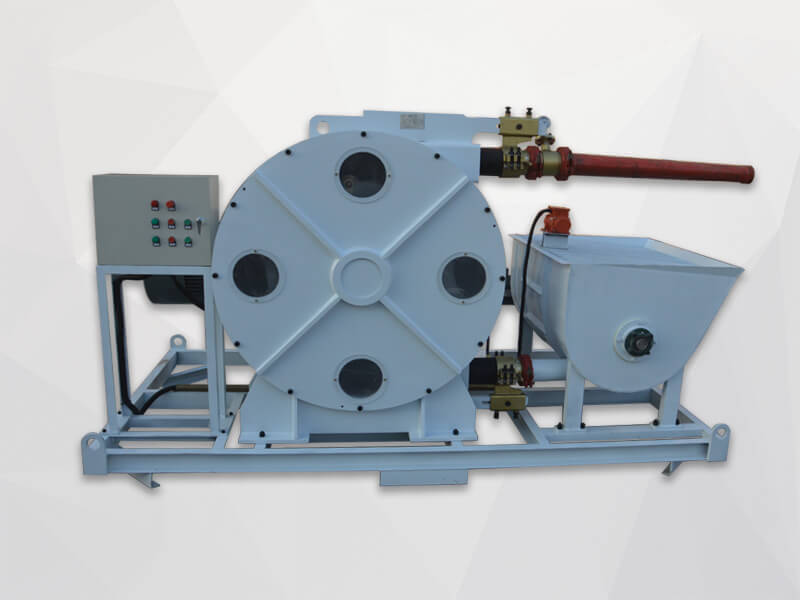

LGP250/700/75PI-E grout injection station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.

Then the mixed slurry is delivered to the grout agitator. Grout pump injects from the mixing drum(storage tank). This ensures a continuous mixing and grouting operations.

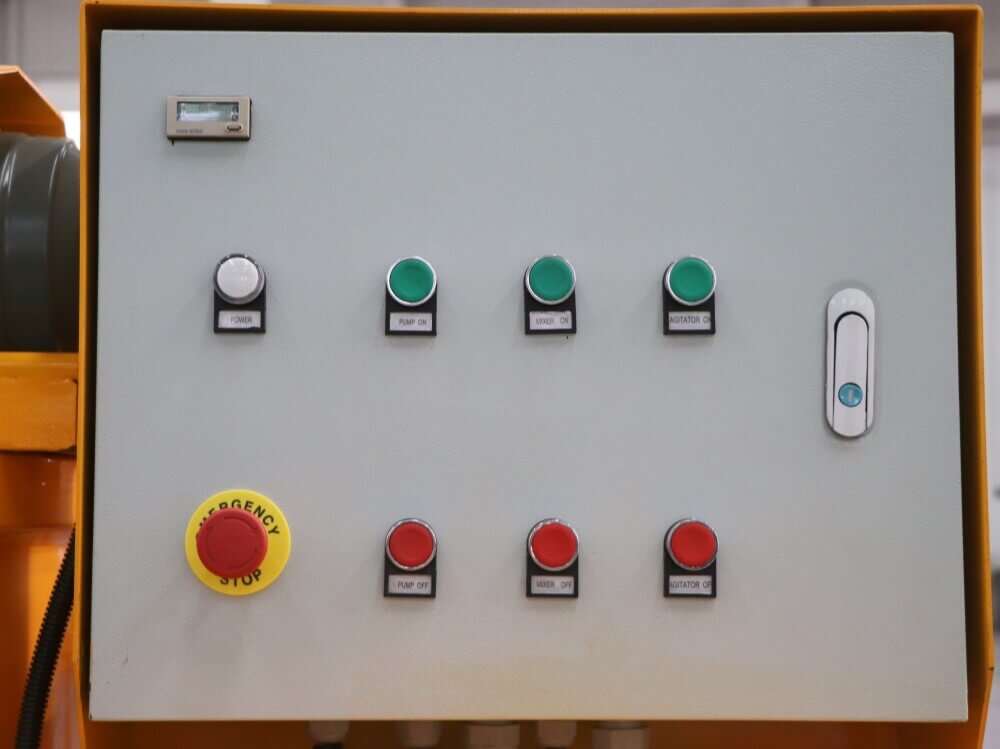

LGP250/700/75PI-E injection grout station is hydraulic drive with electric motor. Grouting pressure and displacement is adjustable. Compact size of the injection station is easy to operate. It also takes up a small space.

Then the mixed slurry is delivered to the grout agitator. Grout pump injects from the mixing drum(storage tank). This ensures a continuous mixing and grouting operations.

LGP250/700/75PI-E injection grout station is hydraulic drive with electric motor. Grouting pressure and displacement is adjustable. Compact size of the injection station is easy to operate. It also takes up a small space.

Application

LGP250/700/75PL-E grout injection plant/station is mainly used to be made bentonite slurry, cement slurry etc. The grout inject station is used for dam, ground construction, underground construction, mining, highway, railway, hydropower and construction etc. projects.

Features

1. Ballvalve.

2. LGP250/700/75PL-E inject grout station has hydraulic drive.

3. Up to 5mm particle size.

4. Single piston and two-acting.

5. The injection grout station is low flow pressure surge system.

6. Vertical type pump with compact size.

7. Grout injection plant has high-speed colloidal grout mixer.

8. Lower charging material height for mixer.

9. Safely releasing pressure when pumping block.

10. Injection station has one and two-oil gear pump to get large output and high pressure in one pump.

2. LGP250/700/75PL-E inject grout station has hydraulic drive.

3. Up to 5mm particle size.

4. Single piston and two-acting.

5. The injection grout station is low flow pressure surge system.

6. Vertical type pump with compact size.

7. Grout injection plant has high-speed colloidal grout mixer.

8. Lower charging material height for mixer.

9. Safely releasing pressure when pumping block.

10. Injection station has one and two-oil gear pump to get large output and high pressure in one pump.

Product Details

Technical Parameters

Technical Data

| Description | Data |

| Grout Injection Station Model | LGP250/700/75PL-E |

| Dimensions | 2710*1100*1820mm |

| Neight | 1060kg |

| Mixer | |

| Capacity | 250L |

| Output | 1100L/min |

| Suitable water/cementratio | ≥0.5:1 |

| Motor Power | 7.5KW |

| Rated Rev. | 1450rpm |

| Agitator | |

| Capacity | 700L |

| Motor Power | 1.5KW |

| Rated Rev. | 35rpm |

| Pump(vertical compact hydraulic grout pump, two oil gearbox) | |

| Output/Pressure | Low pressure: 0-75L/min 0-50bar High Pressure: 0-40L/min 0-100bar |

| Power | 7. 5KW |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LGP800/1200/200PI-D all in one grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit

LGP800/1200/200PI-D all in one grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit -

LGP350/800/70PI-E electric grout plant is a combination of grout pump, grout mixer with agitator in one base frame. The electric grout plant is mainly used to be made bentonite slurry, cement slurry etc.LGP350/800/70PI-E Electric Grout Plant

LGP350/800/70PI-E electric grout plant is a combination of grout pump, grout mixer with agitator in one base frame. The electric grout plant is mainly used to be made bentonite slurry, cement slurry etc.LGP350/800/70PI-E Electric Grout Plant -

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale -

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

.jpg)

.jpg)