Your position:

Home > Products > Grout Mixing Plant

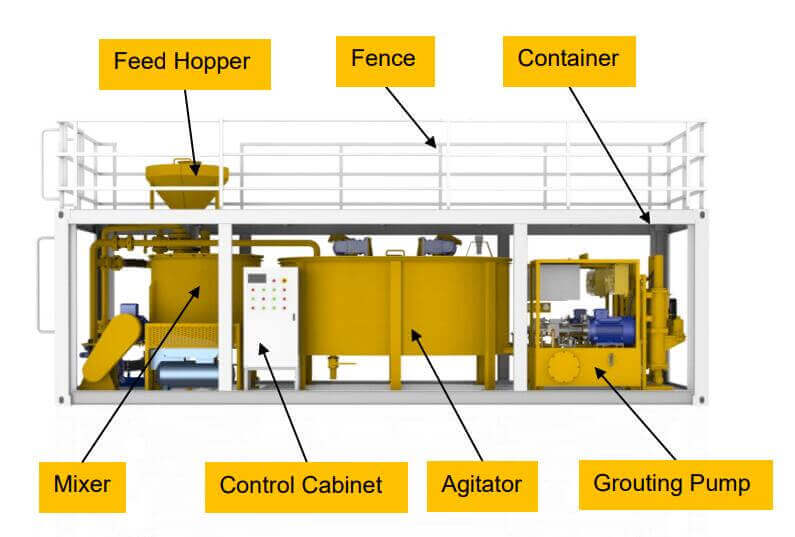

LGP1000/4000/2x165/30PL-E Full automatic container type jet grouting equipment

Container type jet grouting equipment is a grout mixing and pumping system designed to fit inside a shipping container making it highly portable and easy to transport between job sites.

1000L

1200L/min

4000L

36r/min

0-3MPa

2×(0-10m³/h)

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

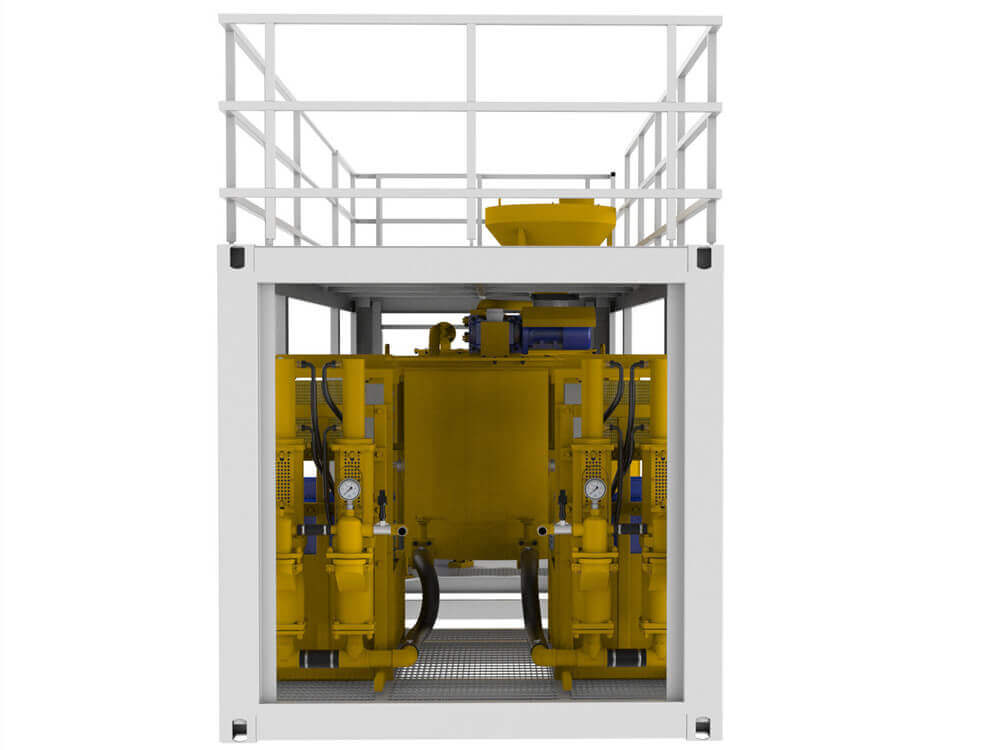

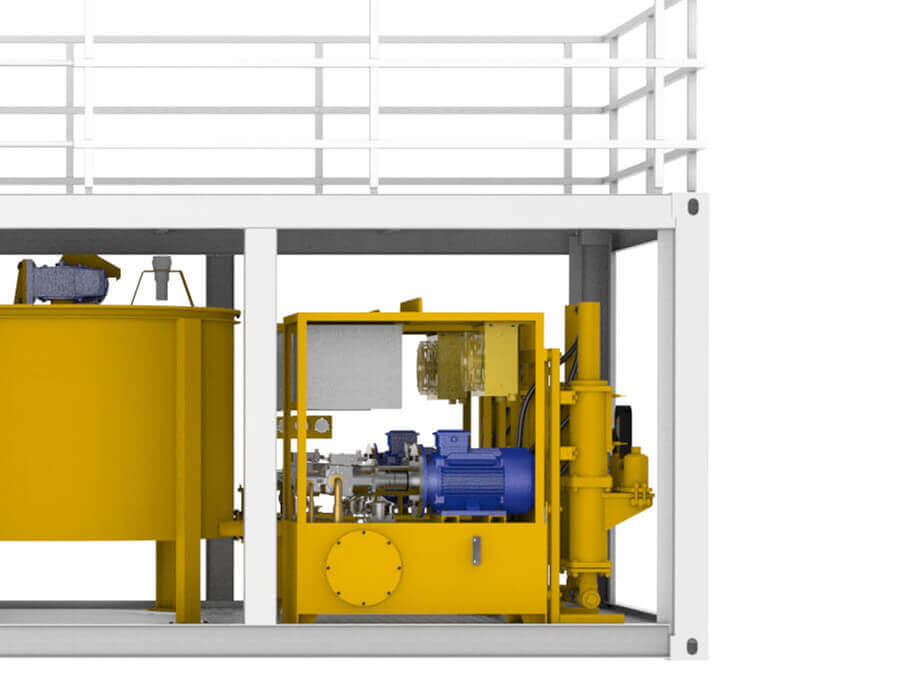

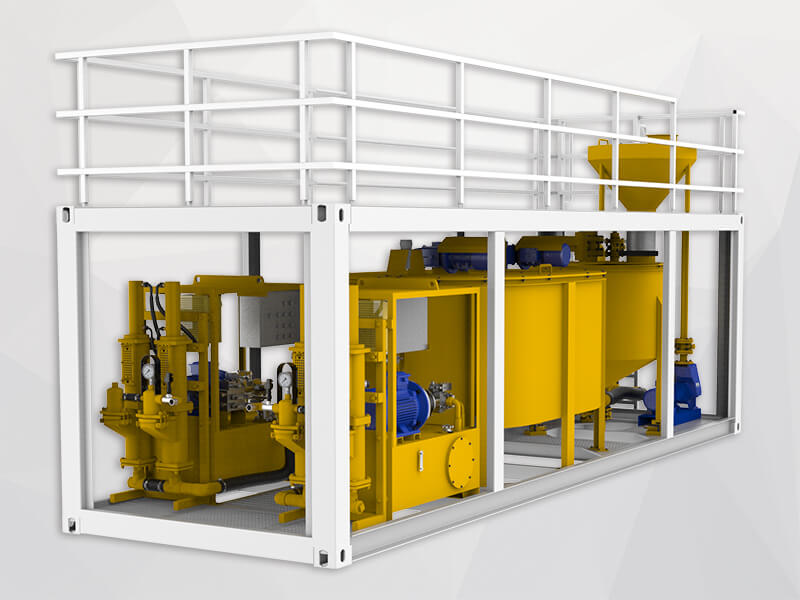

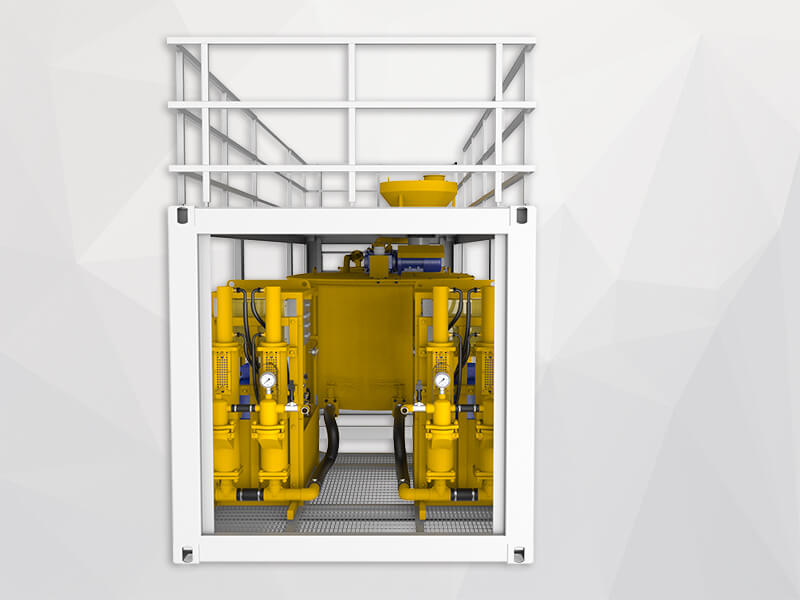

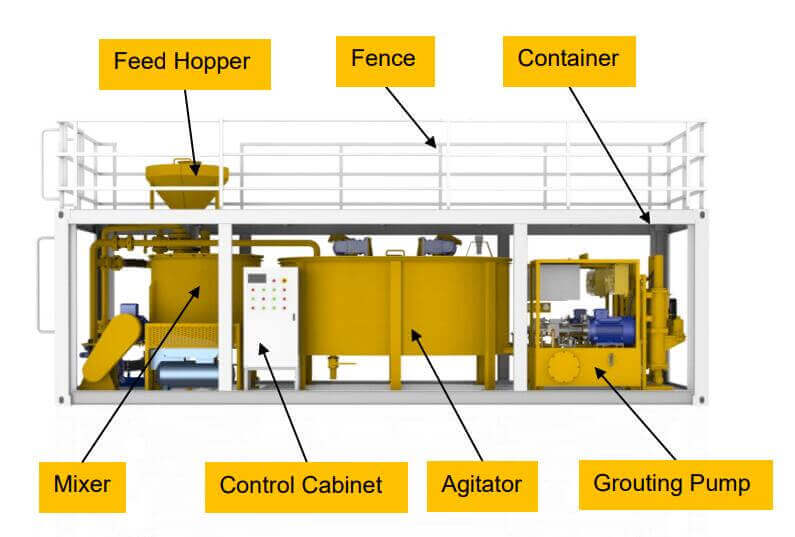

LGP1000/4000/2x165/30PL-E Full automatic container type jet grouting equipment is a fully automated container-type jet grouting equipment designed for the precise proportioning of multiple powdered ingredients and fluids. This system is engineered to handle high flow rates and large volumes of grout or slurry, making it ideal for demanding projects such as cement-bentonite slurry trenching and extensive soil mixing or jet grouting operations.

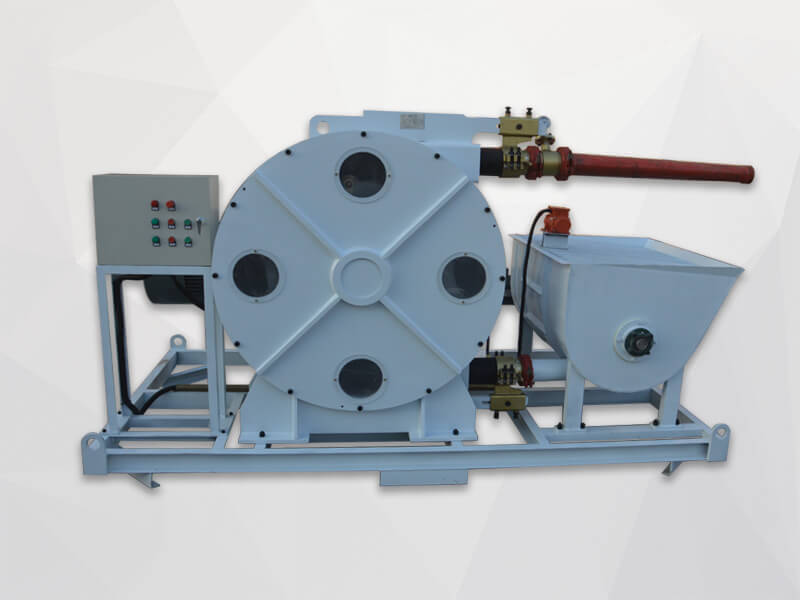

The full automatic jet grouting equipment is capable of producing cement grout by mixing water and cement powder under high turbulence, or bentonite slurry when using water and bentonite powder. It can also prepare more complex mixtures, including ternary or quaternary compounds, with one or two liquid components and a solid component. The prepared grout or slurry is then transferred to other units via a plunger pump (with the option of two sets) depending on the specific geotechnical application.

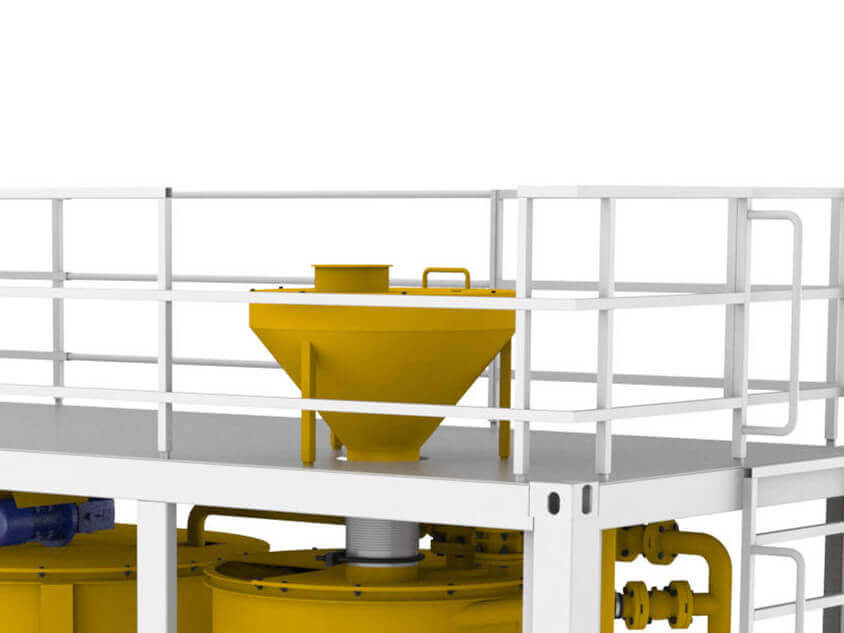

This container type jet grouting equipment is designed to fit within a shipping container, making it highly portable and easy to transport between construction sites. Its containerized design facilitates quick installation and use, allowing it to adapt to a variety of complex construction scenarios and to work in conjunction with other equipment as needed. The system includes built-in feed rate adjustments and provides continuous density measurements to the operator, who can make real-time adjustments to the grout or slurry proportions to ensure accuracy.

The full automatic jet grouting equipment is capable of producing cement grout by mixing water and cement powder under high turbulence, or bentonite slurry when using water and bentonite powder. It can also prepare more complex mixtures, including ternary or quaternary compounds, with one or two liquid components and a solid component. The prepared grout or slurry is then transferred to other units via a plunger pump (with the option of two sets) depending on the specific geotechnical application.

This container type jet grouting equipment is designed to fit within a shipping container, making it highly portable and easy to transport between construction sites. Its containerized design facilitates quick installation and use, allowing it to adapt to a variety of complex construction scenarios and to work in conjunction with other equipment as needed. The system includes built-in feed rate adjustments and provides continuous density measurements to the operator, who can make real-time adjustments to the grout or slurry proportions to ensure accuracy.

Application

LGP1000/4000/2x165/30PL-E Full automatic container type jet grouting equipment application:

1. Anchor injection

2. Jet grouting

3. Drilling

4. Concreting

5. Cavity filling

6. Bottom injection

7. Tunnel construction applications

8. Dam applications

1. Anchor injection

2. Jet grouting

3. Drilling

4. Concreting

5. Cavity filling

6. Bottom injection

7. Tunnel construction applications

8. Dam applications

Features

1. Up to 5mm particle size.

2. The proportion of materials in the formula can be adjusted freely.

3. The preparation of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid component.

4. Cement can be added by screw feeder automatically.

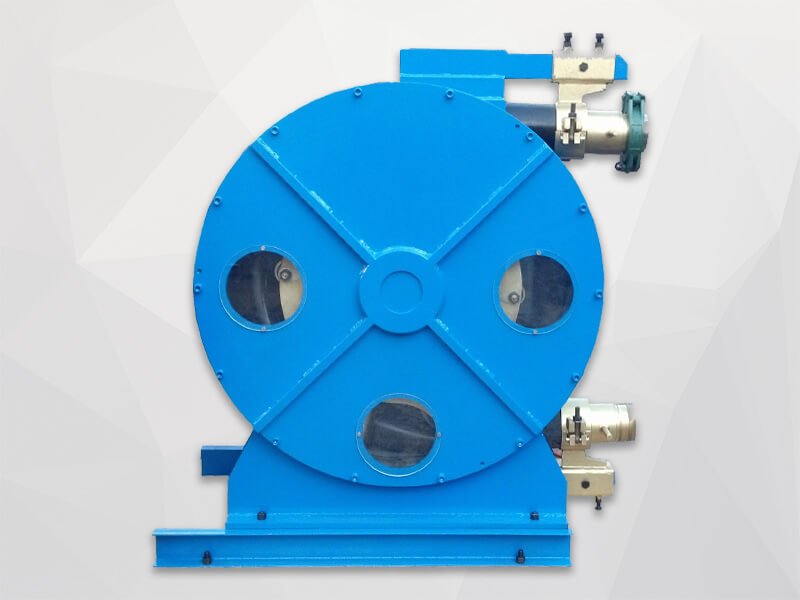

5. A high-speed colloidal grout mixer and a high-speed vortex mixer ensure that the mixture is mixed quickly and evenly.

6. The mixer, slurry pump and agitator have an automatic cleaning function.

7. Output and pressure can be step-less adjusting.

8. Main pipeline valves are all pneumatic valves.

9. Independent of pressure ratios, the suction stroke is always carried out at high velocity in order to flush the valves and avoid clogging.

10. Container type jet grouting plant can be placed directly in the 40ft cabinet.

11. Container type jet grouting station is equipped with some ceiling lamps, for illuminating the different working areas.

12. Flameproof electric cabinet, protection grade IP56.

13. The full automatic jet grouting plant has compact structure, a whole grout plant with mixing and grouting.

14. There are two operation modes: automatic mode and manual mode.

15. Automated mixing and grouting plant is simple to operate and easy to maintain.

16. Standard seal parts to ensure excellent seal quality.

17. Tank body manufactured by the thicker plate for more reliable work and longer use life.

18. High productivity due to ergonomically positioned operating elements.

19. High reliability and low-maintenance operation.

2. The proportion of materials in the formula can be adjusted freely.

3. The preparation of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid component.

4. Cement can be added by screw feeder automatically.

5. A high-speed colloidal grout mixer and a high-speed vortex mixer ensure that the mixture is mixed quickly and evenly.

6. The mixer, slurry pump and agitator have an automatic cleaning function.

7. Output and pressure can be step-less adjusting.

8. Main pipeline valves are all pneumatic valves.

9. Independent of pressure ratios, the suction stroke is always carried out at high velocity in order to flush the valves and avoid clogging.

10. Container type jet grouting plant can be placed directly in the 40ft cabinet.

11. Container type jet grouting station is equipped with some ceiling lamps, for illuminating the different working areas.

12. Flameproof electric cabinet, protection grade IP56.

13. The full automatic jet grouting plant has compact structure, a whole grout plant with mixing and grouting.

14. There are two operation modes: automatic mode and manual mode.

15. Automated mixing and grouting plant is simple to operate and easy to maintain.

16. Standard seal parts to ensure excellent seal quality.

17. Tank body manufactured by the thicker plate for more reliable work and longer use life.

18. High productivity due to ergonomically positioned operating elements.

19. High reliability and low-maintenance operation.

Technical Parameters

Technical Data

| LGP1000/4000/2x165/30PL-E Full automatic container type jet grouting equipment specification : | |||

| 1. Two modes of operation:fully automatic mode and manual mode. 2. Automatic cleaning system. 3. The preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid component. 4. Output and pressure can be step-less adjusting. 5. High reliability and low-maintenance operation with good accessibility to the wear parts. 6. Can be placed directly in the 40ft cabinet. |

|||

| LGP1000/4000/2x165/30PL-E Automatic jet grouting equipment | |||

| Mixer | Agitator | ||

| Volume | 1000L | Volume | 4000L |

| Flow | 1200L/min | Speed | 36r/min |

| Max. output | 20m³/h | Level sensor | Ultrasonic sensor |

| Power | 15Kw | Power | 2×3.0Kw |

| Air supply system | Water supply system | ||

| Flow | 280L/min | Flow@Lift | 5.6L/s@30m |

| Power | 2.2Kw | Power | 4.0Kw |

| Grout Pump | |||

| Pressure | 0-3MPa | Plunger | 120mm |

| Flow | 2×(0-10m³/h) | Plunger stroke | 200mm |

| Oil tank | 2×180L | Cylinder bore | 80mm |

| Power | 2×15Kw | Cylinder rod dia. | 45mm |

| Size@Weight | 7200mm(L)×2200mm(W)×3160mm(H)@8.5t | ||

| Power supply | 380V, 50Hz | ||

| Note: 1. All data are tested by water. 2. We can customize products according to your requirements. |

|||

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

The LGP400/1000/95/165DPL-E/A Grout mixer and pump with wheels play a crucial role in the creation of substances like cement slurry or bentonite slurry. This equipment is specifically designed for injecting these mixtures into the subsoil to achieve tasks such as soil consolidation, piling, or even for the extended transportation of materials.LGP400/1000/95/165DPL-E/A Grout mixer and pump with wheels

The LGP400/1000/95/165DPL-E/A Grout mixer and pump with wheels play a crucial role in the creation of substances like cement slurry or bentonite slurry. This equipment is specifically designed for injecting these mixtures into the subsoil to achieve tasks such as soil consolidation, piling, or even for the extended transportation of materials.LGP400/1000/95/165DPL-E/A Grout mixer and pump with wheels -

Automated mixing and grouting plants for colloidal mixing and injection of suspensions for a range of different applications as well.LGP1200/1200/2X75/100PI-E Automated mix and grout plant

Automated mixing and grouting plants for colloidal mixing and injection of suspensions for a range of different applications as well.LGP1200/1200/2X75/100PI-E Automated mix and grout plant -

We are high quality automatic grout mixing with pumping equipment supplier and manufactuer from China, if you want to get our grout mixing with pumping equipment quotation or cost, price, you can contact us directly.LGP1000/2X75/100PI-E Automatic grout mixing with pumping equipment

We are high quality automatic grout mixing with pumping equipment supplier and manufactuer from China, if you want to get our grout mixing with pumping equipment quotation or cost, price, you can contact us directly.LGP1000/2X75/100PI-E Automatic grout mixing with pumping equipment -

LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station is colloidal type, with high shear high speed, could mixing cement, mortar, water, bentonite etc.LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station

LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station is colloidal type, with high shear high speed, could mixing cement, mortar, water, bentonite etc.LGP300/300/300/70/80PI-E Cement slurry and mortar pumping station

.jpg)

.jpg)