Your position:

Home > Products > Grout Mixing Plant

LGP500/700/100PI-D Colloidal grout plant for sale

LGP500/700/100PI-D colloidal grout plant for grouting applications that require colloidal mixing like dams, tunnel lining, post-tensioning, underwater foundation, deep well casing, slope line grouting, soil, earth foundation stabilization, waterproofing, underground mining and many heavy construction jobs.

LGP500/700/100PI-D

25kw/36HP

2200r/min

2900*1960*1550mm

1790kg

500L

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

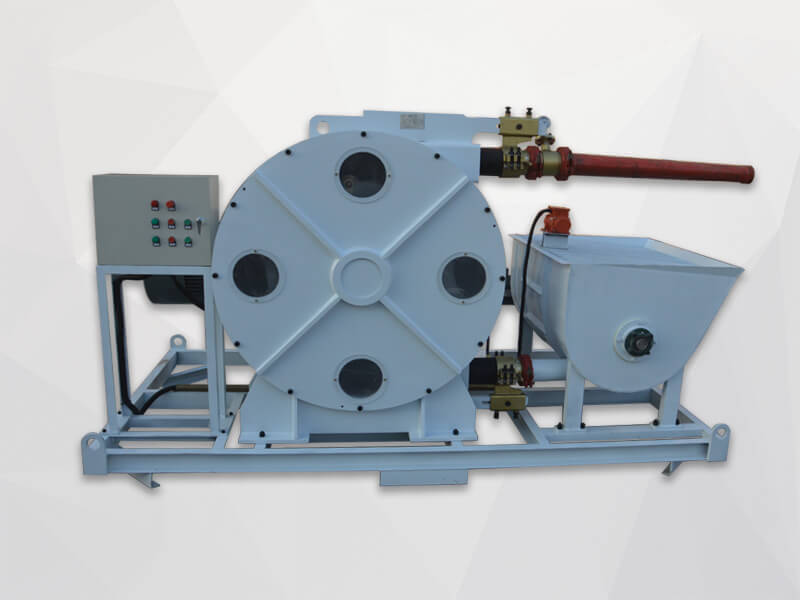

Leadcrete LGP500/700/100PI-D colloidal series grout plant units are heavy duty, The Leadcrete colloidal series colloidal grout unit easily mixes and pumps slurries of neat cement, fly ash, bentonite, microfine cements and lime flour. The LGP500/700/100PI-D colloidal grout mixer pump units are available with an 500L colloidal mixer, it is designed to provide a continuous mixing and pumping operation.

These units feature a Leadcrete, a 700L agitator storage tank and a hydraulic two cylinder piston pump. The colloidal mixer is equipped with a centrifugal diffuser-type pump rotating at speeds up to 1500rpm that disperses the cementitous material down to its finest particle size to achieve complete particle wetness.

The mixing tank is also equipped with a bridge breaker to break apart the material before entering the colloidal mix pump. The agitated storage tank is equipped with a variable speed high-efficiency paddle mixer that maintains a thoroughly mixed grout while waiting to be pumped. The grout pump is connected directly to the agitated storage tank to provide a continuous pumping operation. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning and maintenance. The colloidal grout station plant is hydraulic drive with compact structure, convenient operation, less space occupation. The output is stepless variable.

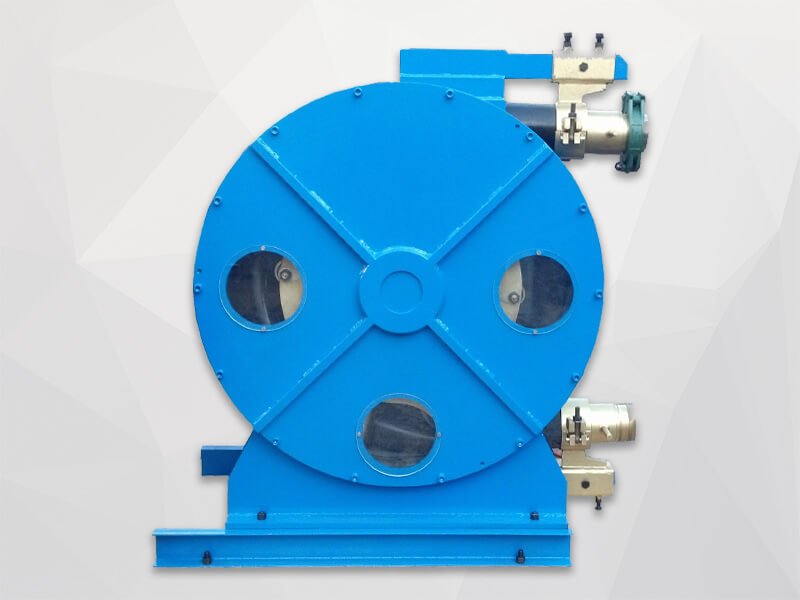

LGP500/700/100PI-D Colloidal grout plant Component

This plant is combination of mixer, agitator, grout pump, hydraulic power pack, diesel engine, electric control, squeeze handle, etc. The worldwide famous brand hydraulic elements ensure the safety. The diesel is Changchai EH36 diesel engine which ensures the power supply.

These units feature a Leadcrete, a 700L agitator storage tank and a hydraulic two cylinder piston pump. The colloidal mixer is equipped with a centrifugal diffuser-type pump rotating at speeds up to 1500rpm that disperses the cementitous material down to its finest particle size to achieve complete particle wetness.

The mixing tank is also equipped with a bridge breaker to break apart the material before entering the colloidal mix pump. The agitated storage tank is equipped with a variable speed high-efficiency paddle mixer that maintains a thoroughly mixed grout while waiting to be pumped. The grout pump is connected directly to the agitated storage tank to provide a continuous pumping operation. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning and maintenance. The colloidal grout station plant is hydraulic drive with compact structure, convenient operation, less space occupation. The output is stepless variable.

LGP500/700/100PI-D Colloidal grout plant Component

This plant is combination of mixer, agitator, grout pump, hydraulic power pack, diesel engine, electric control, squeeze handle, etc. The worldwide famous brand hydraulic elements ensure the safety. The diesel is Changchai EH36 diesel engine which ensures the power supply.

Application

LGP500/700/100PI-D colloidal grout plant for grouting applications that require colloidal mixing like dams, tunnel lining, post-tensioning, underwater foundation, deep well casing, slope line grouting, soil, earth foundation stabilization, waterproofing, underground mining and many heavy construction jobs.

Features

1. LGP500/700/100PI-D colloidal grout plant is with ISO, CE certificate.

2. Butterfly valve of mixer and agitator.

3. Operation and maintenance are simple.

4. Yuken relief valve and directional valve for hydraulic system of grout pump.

5. Compact size, it is combination of mixer, agitator and piston grout pump in one base frame.

6. Oil temperature gauge can automatically control cooler fan working in normal temperature rang, if temperature is too high, the machine will stop work automatically.

7. Colloidal grout plant for sale with best price.

2. Butterfly valve of mixer and agitator.

3. Operation and maintenance are simple.

4. Yuken relief valve and directional valve for hydraulic system of grout pump.

5. Compact size, it is combination of mixer, agitator and piston grout pump in one base frame.

6. Oil temperature gauge can automatically control cooler fan working in normal temperature rang, if temperature is too high, the machine will stop work automatically.

7. Colloidal grout plant for sale with best price.

Product Details

Technical Parameters

Technical Data

| Colloidal grout plant type | LGP500/700/100PI-D Colloidal grout plant |

| Diesel engine | 25kw/36HP |

| Rotating speed of engine | 2200r/min |

| Dimensions | 2900*1960*1550mm |

| Weight | 1790kg |

| Mixer | |

| Capacity | 500L |

| W/C ratio | 0.5-1 |

| Rated Rev. | 1500rpm |

| Agitator | |

| Volume | 700L |

| Rated Rev. | 36rpm |

| Pump | |

| Type | Hydraulic Two Cylinder Piston Pump |

| Pressure | 0-50 bar |

| Output | 0-100L/min |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station -

LGP800/1200/200PI-D all in one grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit

LGP800/1200/200PI-D all in one grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit -

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale

LGP400/700/80PL-E Grout Station for Sale is mainly is used for mining, dam foundations, tunnels, soil permeation, soil and rock grouting, microfine cements, penetration grouting, soil anchors, soil nails, rock bolts, pile encasements, waterproofing and post tensioning etc. projects.LGP400/700/80PL-E Grout Station for Sale -

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

.jpg)

.jpg)