Your position:

Home > Products > Grout Mixing Plant

LBP1000/1600/20HP-E Automatic Bentonite Grout Unit

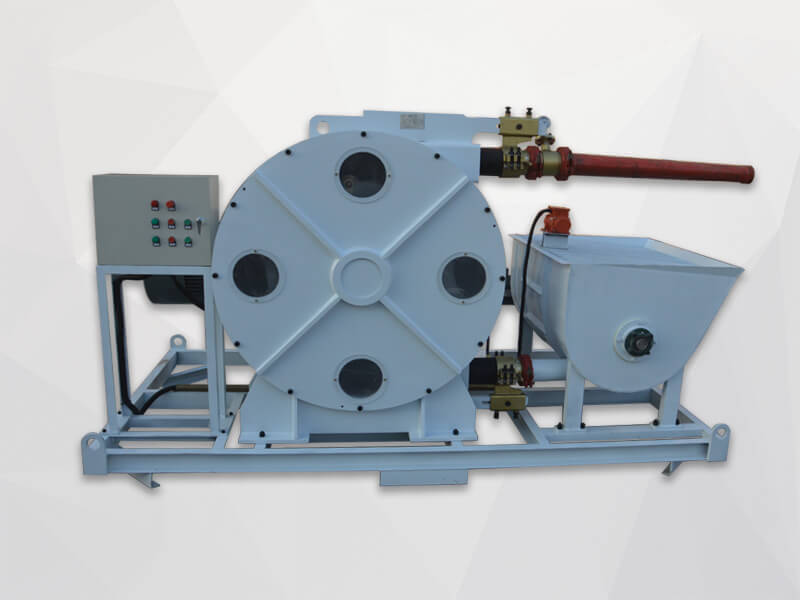

LBP1000/1600/20HP-E automatic bentonite grout unit consists of a steel sheet cylindrical tank, set-up on a strong base frame, the grout pump and the motor. LBP bentonite grout unit system would be used for the mixing and pumping of the cementitious powders, water, pozzolans and admixtures.

LBP1000/1600/20HP-E

20m3/h

1.5Mpa

4300*2250*2200mm

2600kg

2.2Kw, 50Hz, 380V

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

LBP1000/1600/20HP-E automatic bentonite grout unit consists of a steel sheet cylindrical tank, set-up on a strong base frame, the grout pump and the motor. LBP bentonite grout unit system would be used for the mixing and pumping of the cementitious powders, water, pozzolans and admixtures. The muds are mixed through a high speed vortex produced by a special pump which, after sucking the material from the bottom of the tank, sends it back tangentially into the same tank in order to get thehighest possible efficiency.

Through the time-controlled operation of the system's pneumatic pinch valve, the pump can take the mud to a storage container or directly to the area of use. By this process it is possible to obtain homogeneous colloidal and high quality mixtures within a very short period of time.

Through the time-controlled operation of the system's pneumatic pinch valve, the pump can take the mud to a storage container or directly to the area of use. By this process it is possible to obtain homogeneous colloidal and high quality mixtures within a very short period of time.

Application

1. Bentonite grout unit is used for mining - tunnel lining, contact grouting, shaft waterproofing.

2. Utilities - encasements, waterproofing, slope line grouting.

3. Civil Engineering - dam foundations, tunnels, mining, soil nails, tiebacks, earth anchors, cable and rock bolts.

4. Automatic grout unit is used for construction - pavement under sealing, slab jacking and slab raising.

5. Structural - building and bridge restoration, foundation stabilization, foundation raising, soil compaction grouting and soil & rock grouting.

6. Geotechnical - deep well casing, monitor wells, well sealing and abandonment.

2. Utilities - encasements, waterproofing, slope line grouting.

3. Civil Engineering - dam foundations, tunnels, mining, soil nails, tiebacks, earth anchors, cable and rock bolts.

4. Automatic grout unit is used for construction - pavement under sealing, slab jacking and slab raising.

5. Structural - building and bridge restoration, foundation stabilization, foundation raising, soil compaction grouting and soil & rock grouting.

6. Geotechnical - deep well casing, monitor wells, well sealing and abandonment.

Features

1. With the function of record and display grouting pump reciprocating times by a counter.

2. Grouting pressure and output are step-less adjustable.

3. LBP1000/1600/20HP-E Automatic Bentonite Grout Unit using rectangular agitator, makes the automatic bentonite grout unit has compact structure, small size.

4. Grout mixer and agitator switch is a squeeze handle that is easy to operate and reliable.

5. Grouting pump has high speed and low speed by rotating ball valve switch.

6. Hydraulic reversing and hydraulic drive for vertical grouting pump.

7. With a air cooler and a water cooler, to adapt to different working environment temperature.

2. Grouting pressure and output are step-less adjustable.

3. LBP1000/1600/20HP-E Automatic Bentonite Grout Unit using rectangular agitator, makes the automatic bentonite grout unit has compact structure, small size.

4. Grout mixer and agitator switch is a squeeze handle that is easy to operate and reliable.

5. Grouting pump has high speed and low speed by rotating ball valve switch.

6. Hydraulic reversing and hydraulic drive for vertical grouting pump.

7. With a air cooler and a water cooler, to adapt to different working environment temperature.

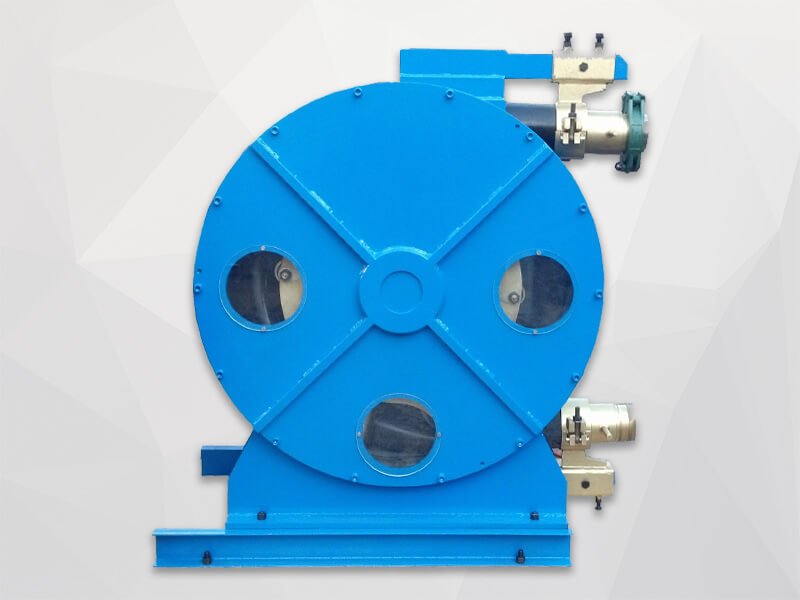

Product Details

Technical Parameters

Technical Data

| Description | Data |

| Automatic Bentonite Grout Unit Model | LBP1000/1600/20HP-E |

| Dimensions | 4300*2250*2200mm |

| Weight | 2600kg |

| Mixer | |

| Tank Capacity | 1200L |

| Output | 18-20m3/h |

| Cyclic Pump | 1350L/min |

| Power | 15Kw, 50Hz, 380V |

| Rated Rev. | 1450rpm |

| Agitator | |

| Capacity | 1600L |

| Rated Rev. | 40rpm |

| Power | 2.2Kw, 50Hz, 380V |

| Hose Pump | |

| Output | 20m3/h |

| Max. Pressure | 1.5Mpa |

| Power | 18.5Kw, 50Hz, 380V |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LGP800/1200/200PI-D grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit

LGP800/1200/200PI-D grout plant unit is a combination of mixer, agitator and grout pump in one plant unit. The grout unit is mainly used in hydropower, construction, mining, highway, railway and other ground and underground construction.LGP800/1200/200PI-D Grout Plant Unit -

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station

LGP250/700/75PI-E grout inject station is a combination of grout mixer, agitator and grout pump in one base frame. High speed vortex mixer of the grout injection plant ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into homogeneous slurry.LGP250/700/75PI-E Grout Injection Station -

LGP350/800/70PI-E electric grout plant is a combination of grout pump, grout mixer with agitator in one base frame. The electric grout plant is mainly used to be made bentonite slurry, cement slurry etc.LGP350/800/70PI-E Electric Grout Plant

LGP350/800/70PI-E electric grout plant is a combination of grout pump, grout mixer with agitator in one base frame. The electric grout plant is mainly used to be made bentonite slurry, cement slurry etc.LGP350/800/70PI-E Electric Grout Plant -

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

LGP300/300/75 PI-E China compact grout plant is mainly suitable for mixing and pumping water, cement, sand, bentonite, filler, clay power, silicates and other additivesLGP300/300/75 PI-E China compact grout plant

.jpg)

.jpg)