Your position:

Home > Products > Grout Mixer

LMA20 Automatic cement bentonite mud mixing batching station with cement silo in container

Automatic cement bentonite mud mixing batching station finds application in various construction projects that require the use of cement bentonite mud. It is commonly used in the construction of cutoff walls, diaphragm walls, slurry walls, and other geotechnical applications where the containment of soil and groundwater is necessary.

1000L

1200L/min

20m³/h

15Kw

1100L

25r/min

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

HCS17B horizontal cement silo is designed based on 20ft container size. More container silos can be stacked together to work. It can be stored in standard container directly. This can save shipping cost.

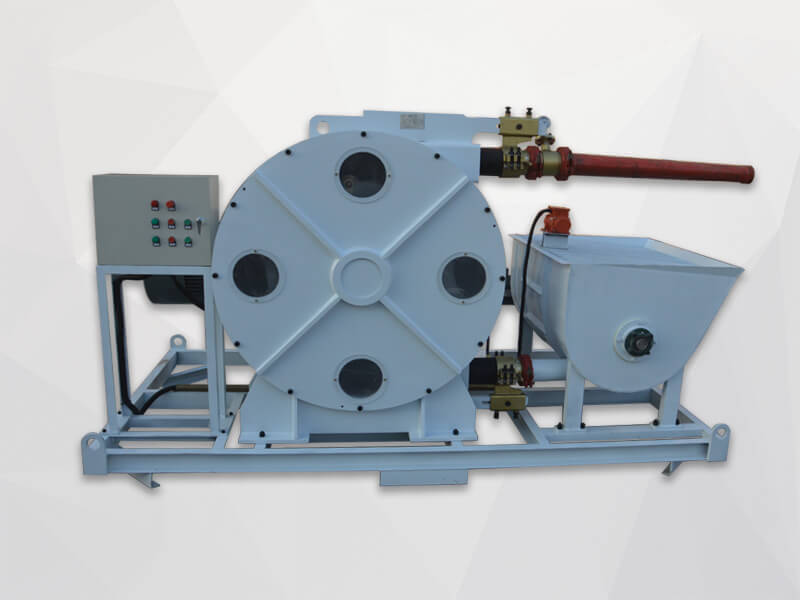

LMA20 Automatic cement bentonite mud mixing batching station is making reference to, was mainly conceived in order to obtain, through a high turbulence mixing of water and cement powder, a cement mixture (cement grout), or, by using water and bentonite powder, a bentonite sully for plastic muds. Also the preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid components (for every screw conveyor).

The cement mixture or the bentonite sully is then transferred to the other units, according with the type of foreseen geotechnical machines.

Automatic cement bentonite mud mixing plant can be work under container silo. 20ft and 40ft container silo both are provided.

LMA20 Automatic cement bentonite mud mixing batching station is making reference to, was mainly conceived in order to obtain, through a high turbulence mixing of water and cement powder, a cement mixture (cement grout), or, by using water and bentonite powder, a bentonite sully for plastic muds. Also the preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid components (for every screw conveyor).

The cement mixture or the bentonite sully is then transferred to the other units, according with the type of foreseen geotechnical machines.

Automatic cement bentonite mud mixing plant can be work under container silo. 20ft and 40ft container silo both are provided.

Application

The automatic bentonite mud mixing plant is specifically designed for the efficient mixing and preparation of bentonite mud. The following is the application range of the grouting mixer station:

1. Drilling Fluids

Bentonite mud is commonly used as a key component in drilling fluids for oil and gas exploration, as well as in geotechnical and environmental drilling. The cement bentonite mud mixing batching station ensures the proper mixing and consistency of the drilling fluid, which helps to lu bricate the drill bit, cool and clean the drill string, and carry drill cuttings to the surface.

2. Trenchless Technology

In trenchless construction methods such as horizontal directional drilling (HDD) and microtunneling, bentonite mud is used as a drilling fluid to stabilize the borehole and support the excavation. The cement bentonite mixing batching station provides a continuous supply of properly mixed bent onite mud, ensuring smooth and efficient drilling operations.

3. Piling and Foundation Construction

Bentonite mud is also used in piling and foundation construction. It is used to stabilize the borehole during drilling and prevent collapse. The cement bentonite mud mixing station with cement silo ensures the consistent and accurate preparation of bentonite mud, which is crucial for maintaining the stability and in tegrity of the drilled shafts or piles.

4. Tunneling and Underground Construction

In tunneling and underground construction projects, bentonite mud is used for various purposes, such as lubrication, stabilization, and groundwater control. The automatic cement bentonite mixing station in container ensures the reliable and efficient preparation of bentonite mud, which is essential for the success of tunneling operations.

5. Environmental Remediation

Bentonite mud is utilized in environmental remediation projects, particularly for the construction of cutoff walls and barriers to contain contaminated groundwater or prevent the migration of pollutants. The cement slurry grout batching plant enables the precise and con persistent preparation of bentonite mud, ensuring the effectiveness of the remediation measures.

6. Civil Engineering and Construction

The automatic high capacity colloidal cement grout mixer can be used in various civil engineering and construction applications where the properties of bentonite mud are required. This includes applications such as grouting, soil stabilization, and sealing of underground structures.

The automatic bentonite mud mixing plant plays a crucial role in ensuring the proper preparation and consistency of bentonite mud for a wide range of applications in drilling, construction, and environmental projects. Its automated operation and precise mixing capabilities contribute to improved efficiency and quality in these applications.

1. Drilling Fluids

Bentonite mud is commonly used as a key component in drilling fluids for oil and gas exploration, as well as in geotechnical and environmental drilling. The cement bentonite mud mixing batching station ensures the proper mixing and consistency of the drilling fluid, which helps to lu bricate the drill bit, cool and clean the drill string, and carry drill cuttings to the surface.

2. Trenchless Technology

In trenchless construction methods such as horizontal directional drilling (HDD) and microtunneling, bentonite mud is used as a drilling fluid to stabilize the borehole and support the excavation. The cement bentonite mixing batching station provides a continuous supply of properly mixed bent onite mud, ensuring smooth and efficient drilling operations.

3. Piling and Foundation Construction

Bentonite mud is also used in piling and foundation construction. It is used to stabilize the borehole during drilling and prevent collapse. The cement bentonite mud mixing station with cement silo ensures the consistent and accurate preparation of bentonite mud, which is crucial for maintaining the stability and in tegrity of the drilled shafts or piles.

4. Tunneling and Underground Construction

In tunneling and underground construction projects, bentonite mud is used for various purposes, such as lubrication, stabilization, and groundwater control. The automatic cement bentonite mixing station in container ensures the reliable and efficient preparation of bentonite mud, which is essential for the success of tunneling operations.

5. Environmental Remediation

Bentonite mud is utilized in environmental remediation projects, particularly for the construction of cutoff walls and barriers to contain contaminated groundwater or prevent the migration of pollutants. The cement slurry grout batching plant enables the precise and con persistent preparation of bentonite mud, ensuring the effectiveness of the remediation measures.

6. Civil Engineering and Construction

The automatic high capacity colloidal cement grout mixer can be used in various civil engineering and construction applications where the properties of bentonite mud are required. This includes applications such as grouting, soil stabilization, and sealing of underground structures.

The automatic bentonite mud mixing plant plays a crucial role in ensuring the proper preparation and consistency of bentonite mud for a wide range of applications in drilling, construction, and environmental projects. Its automated operation and precise mixing capabilities contribute to improved efficiency and quality in these applications.

Features

Automatic cement bentonite mud mixing plant features:

1. LMA20 Grout mixer station can be placed directly in the 20ft cabinet.

2. Up to 5mm particle size.

3. Two modes of operation:fully automatic mode and manual mode.

4. Easy to operate and maintain.

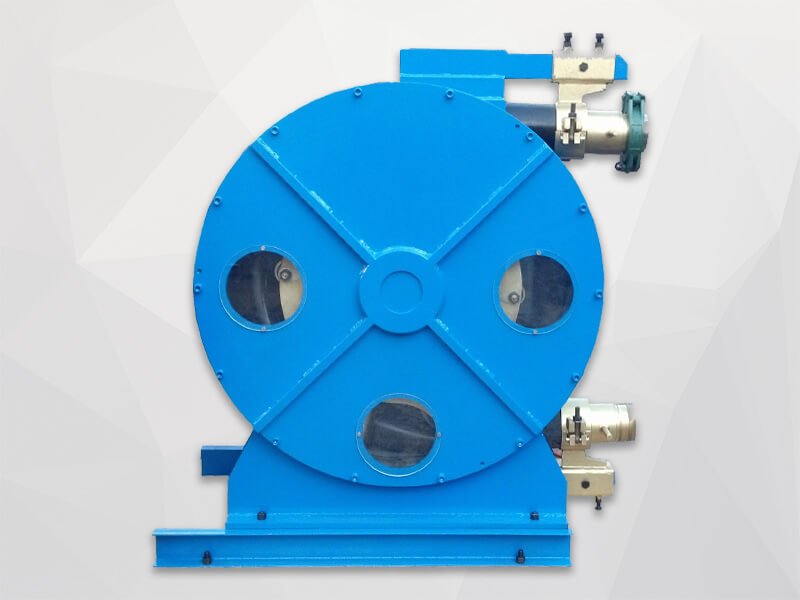

5. High-speed high capacity colloidal grout mixer.

6. Mixture, cycling pump and agitator have automatic cleaning function.

7. Main pipeline valves are all pneumatic valves.

8. Cement can be added by cement silo or screw feeder automatically.

9. It is Equipped with some ceiling lamps, for illuminating the different working areas.

10. The preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid components

Cement silo features:

1. With dust collector.

2. Pressure relief valve.

3. OLI-WOLONG vibrator.

4. Upper recalling dipstick and lower recalling dipstick.

1. LMA20 Grout mixer station can be placed directly in the 20ft cabinet.

2. Up to 5mm particle size.

3. Two modes of operation:fully automatic mode and manual mode.

4. Easy to operate and maintain.

5. High-speed high capacity colloidal grout mixer.

6. Mixture, cycling pump and agitator have automatic cleaning function.

7. Main pipeline valves are all pneumatic valves.

8. Cement can be added by cement silo or screw feeder automatically.

9. It is Equipped with some ceiling lamps, for illuminating the different working areas.

10. The preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid components

Cement silo features:

1. With dust collector.

2. Pressure relief valve.

3. OLI-WOLONG vibrator.

4. Upper recalling dipstick and lower recalling dipstick.

Product Details

Technical Parameters

Technical Data

| LMA20 Automatic cement bentonite mud mixing batching station with cement silo in container specification: | |||

| 1. Two modes of operation: fully automatic mode and manual mode. | |||

| 2. Automatic cleaning system. | |||

| 3. The preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid components. | |||

| 4. Can be placed directly in the 40ft cabinet. | |||

| HCS17B Cement Silo | |||

| Volume | 17m³ | Conveying | 40t/h |

| Inlet Dia. | 100mm | Outlet Dia. | 273mm |

| Power | 18.5Kw | Power supply | 380V,50Hz |

| LMA20 Automatic cement bentonite mud mixing batching station | |||

| Mixer | Agitator | ||

| Volume | 1000L | Volume | 1100L |

| Flow | 1200L/min | Speed | 25r/min |

| Max. output | 20m³/h | Level sensor | Damped rotation controller |

| Power | 15Kw | Power | 3.0Kw |

| Air supply system | Water supply system | ||

| Flow | 300L/min | Water tank volume | 750L |

| Pressure | 0.8MPa | Flow@lift | 9.03L/s@27.5m |

| Power | 3.0Kw | Power | 3.0Kw |

| Power supply | 380V, 50Hz | ||

| Note: 1. All data are tested by water. | |||

| 2. We can customize cement bentonite mud mixing batching station according to your requirements. | |||

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LMA400-700AW automatic grout mixer can also work with the agitator. The agitator has two functions, one is to avoid precipitation, and the other is to store the mixed cement slurry. In this case, stirring work and continuous grouting can be carried out.LMA400-700AW Automatic grout mixer

LMA400-700AW automatic grout mixer can also work with the agitator. The agitator has two functions, one is to avoid precipitation, and the other is to store the mixed cement slurry. In this case, stirring work and continuous grouting can be carried out.LMA400-700AW Automatic grout mixer -

LMA1500-1200E Cement grout mixer is a combination consist of a steel sheet cylindrical mixer tank heavy-duty slurry pump and agitator tank, set-up on a strong base frame. This cement grout mixer for sale is equipped with an automatic control system that can automatically control the operation of the equipment.LMA1500-1200E Cement grout mixer for sale

LMA1500-1200E Cement grout mixer is a combination consist of a steel sheet cylindrical mixer tank heavy-duty slurry pump and agitator tank, set-up on a strong base frame. This cement grout mixer for sale is equipped with an automatic control system that can automatically control the operation of the equipment.LMA1500-1200E Cement grout mixer for sale -

LMA850-1500E grout mixer for sale is a skid mounted, colloidal grout unit. This system is designed to provide a continuous mixing operation. It is a combination consists of a steel sheet cylindrical mixer tank, heavy-duty slurry pump, and agitator tank set-up on a strong base frame.LMA850-1500E Grout mixer for sale

LMA850-1500E grout mixer for sale is a skid mounted, colloidal grout unit. This system is designed to provide a continuous mixing operation. It is a combination consists of a steel sheet cylindrical mixer tank, heavy-duty slurry pump, and agitator tank set-up on a strong base frame.LMA850-1500E Grout mixer for sale -

LMA750-1500E Grout mixer machine for sale is a combination consist of a steel sheet cylindrical mixer tank heavy-duty slurry pump and agitator tank, set-up on a strong base frame. We are grout mixer machine supplier, grout mixer machine manufacturer for 20 years, if you want to get grout mixer machine price, grout mixer unit price, you can contact us directly.LMA750-1500E Grout mixer machine for sale

LMA750-1500E Grout mixer machine for sale is a combination consist of a steel sheet cylindrical mixer tank heavy-duty slurry pump and agitator tank, set-up on a strong base frame. We are grout mixer machine supplier, grout mixer machine manufacturer for 20 years, if you want to get grout mixer machine price, grout mixer unit price, you can contact us directly.LMA750-1500E Grout mixer machine for sale

.jpg)

.jpg)