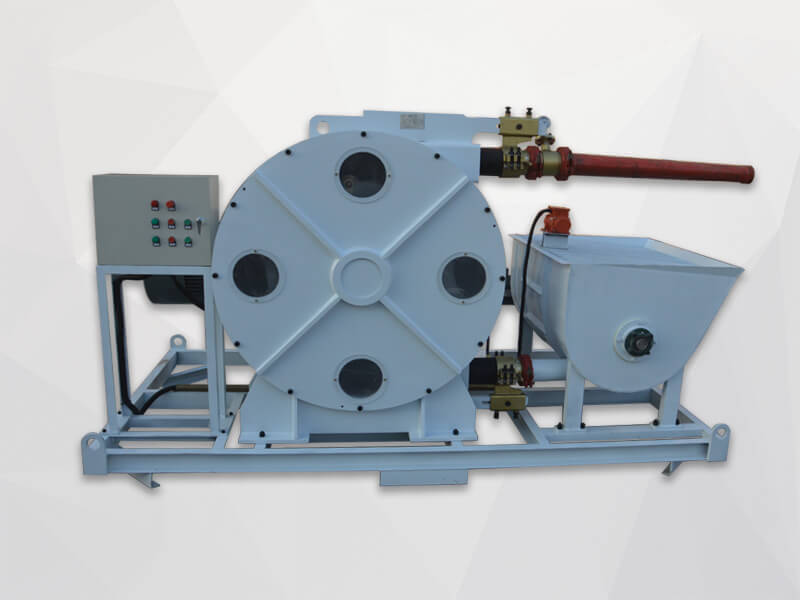

LF40A Foam concrete lightweight concrete work station incorporates a hydraulic push mechanism, providing a high pumping pressure. It enables vertical conveying heights of up to 160 meters and horizontal conveying distances of up to 1000 meters. This makes it suitable for meeting the demands of high-rise building roof insulation projects and long-distance ground filling.

Our company has developed a high and low-pressure density stability technology, which is implemented in this work station. This technology ensures that the density of the lightweight concrete produced by the equipment remains constant, both over short distances and long distances. The density will not be affected by changes in conveying distance or height.

2. The LF40A model is equipped with a lightweight concrete density monitoring and control device, which features a touch screen intelligent control system. The screen provides intuitive display of the equipment's working state and various parameters, facilitating easy assessment of the working state and centralized control.

3. The foam concrete lightweight concrete work station is structured into three layers for powder metering, slurry stirring, and slurry storage.

4. The standard ingredient metering device is included, allowing separate measurement of cement, powder, water, and other materials for precise control of the material ratio.

5. The foam concrete work station is equipped with a standard interface for daily production reports or a printing device. This enables the output or printing of daily consumption of cement, fly ash, blowing agent, and other materials, as well as a summary of the output of lightweight concrete.

6. Our company has developed a lightweight concrete density monitoring and control device that has reached a leading level in the domestic market. This device can be selected to detect the wet density and dry density of the lightweight concrete produced by the equipment, providing reliable data for engineering quality inspections.

7. The foam concrete mixing station features automatic control and is equipped with a lightweight concrete density monitoring and control device. Based on the detected density data, the equipment can automatically adjust the material ratio at the front to ensure that the production of lightweight concrete meets the required density control.

|

Item |

LF40A Foam concrete lightweight concrete work station |

Note |

|||

|

Pump and foam

system |

Output(m3/h) |

40 |

Density 450kg/m3 |

||

|

Convey distance(m) |

Horizontal |

1200 |

|

||

|

Vertical |

160 |

|

|||

|

Motor power(kw) |

Pump motor |

30 |

|

||

|

Foaming system |

11 |

|

|||

|

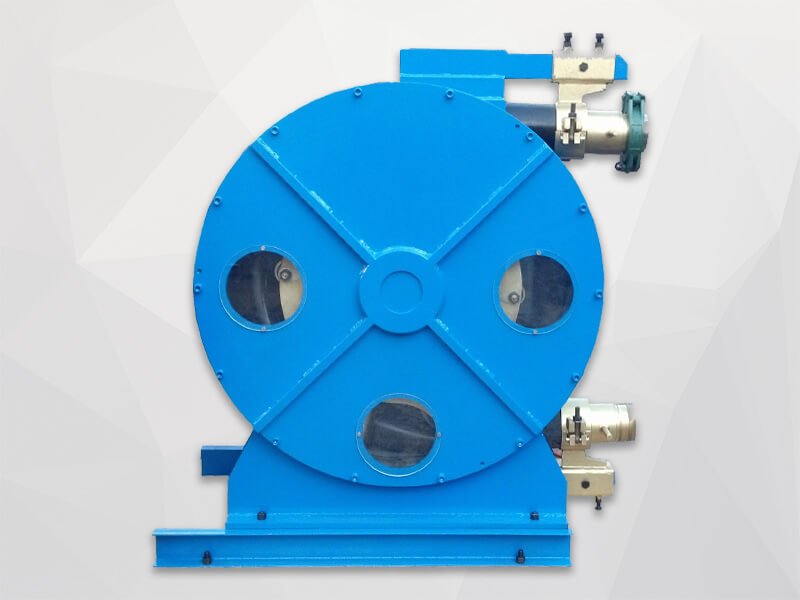

Diameter of concrete cylinder(mm) |

Φ120 |

|

|||

|

Pumping form |

Ball valve double cylinder hydraulic push |

|

|||

|

Density range of lightweight concrete(kg/m3) |

350-800 |

|

|||

|

Foaming ratio |

Adjustable |

|

|||

|

Wet density testing of lightweight concrete |

Accuracy<5% |

Options |

|||

|

Dry density testing of lightweight concrete |

Accuracy<5% |

Options |

|||

|

Cement slurry flow detection display |

Accuracy<2% |

Options |

|||

|

Light concrete flow test shows |

Accuracy<2% |

Options |

|||

|

Foaming agent flow detection shows |

Accuracy<2% |

Options |

|||

|

Conveying pipe diameter(mm) |

Φ50 |

|

|||

|

Mix system |

Volume of mixer(L) |

600 |

|

||

|

Volume of material storage mixer(L) |

720 |

|

|||

|

Motor power(kw) |

Mixer |

5.5 |

|

||

|

Storage mixer |

4 |

|

|||

|

Water pump |

0.75 |

|

|||

|

Screw conveyor |

5.5 |

|

|||

|

Screw conveyor |

φ165x6m |

|

|||

|

Weighing system |

Cumulative weighing |

|

|||

|

Control system

|

Control model |

PLC control, touch screen display and input |

|

||

|

Parameters to print |

Lightweight concrete proportioning printing |

Optional accessories | |||

|

Lightweight concrete productivity printing |

Optional accessories | ||||

|

Size |

The host part (LxWxH mm) |

4100x1750x2065 |

|

||

|

Weight(kg) |

3500 |

|

|||

Configuration of main components:

|

Parameter |

LF40A Foam concrete lightweight concrete work station |

|

Main oil |

Hefei wanye |

|

Motor |

Shandonghuali/Qingdaohongqi |

|

Valve group |

Taiwan Northman |

|

Press gauge |

Made in Wuxi |

|

Hydraulic rubber pipe |

Italy Manuli |

|

Seal ring |

USA Parker |

|

PLC Units |

Omron |

|

Intermediate relay |

Omron |

|

Proximity switch |

Schneider Electric |

|

Remote control |

|

|

Button |

Schneider Electric |

Configuration list (including Φ50 delivery hose 100m):

| No. |

Name |

Spec. |

Unit |

Quantity |

Note |

|

1 |

Hydraulic hose |

Φ50-20m/pc |

pc |

5 |

|

|

2 |

Hydraulic hose |

Φ50 |

pc |

5 |

|

|

3 |

Water pump |

QX7-18-0.75 |

set |

1 |

|

|

4 |

Water drum |

3m3 |

pc |

1 |

|

|

5 |

Water drum holder |

|

set |

1 |

|

|

6 |

Piston |

BS25C.1-13(Φ120) |

pc |

2 |

|

|

7 |

O Ring |

LF40A |

set |

1 |

|

|

8 |

Proximity switch |

ZLJ-A18-8ANA-Q |

pc |

1 |

|

|

9 |

Water pump accessories |

|

set |

1 |

|

|

10 |

Canvas cover |

Φ165 |

pc |

1 |

|

|

11 |

Rubber sleeve |

170x12x380 |

pc |

1 |

|

|

12 |

Throat hoop clamp |

Φ165 |

pc |

4 |

|

|

13 |

Foam agent |

HF30 |

drum |

1 |

(200Kg/drum) |

|

14 |

Remote control |

Wireless 220V |

pc |

1 |

|

|

15 |

Tool box |

|

set |

1 |

|

|

16 |

Operate guide |

LF40A |

pc |

1 |

|

|

17 |

Certification |

LF40A |

pc |

1 |

|

-

LF30A fully automatic lightweight concrete equipment is especially suitable for large-scale filling projects, such as roadbeds, slope protection, high-speed rail, highways, bridges, railways, water conservancy and hydropower projects, bridge and culvert filling, mine backfilling, tunnel filling, and large voids that need to be filled inside the mine scale on-site construction.LF30A Fully automatic lightweight concrete equipment

LF30A fully automatic lightweight concrete equipment is especially suitable for large-scale filling projects, such as roadbeds, slope protection, high-speed rail, highways, bridges, railways, water conservancy and hydropower projects, bridge and culvert filling, mine backfilling, tunnel filling, and large voids that need to be filled inside the mine scale on-site construction.LF30A Fully automatic lightweight concrete equipment -

LFC1000-H foam concrete machine is composed of mixer, agitator, foam generator, hose pump, equipped with screw feeder, belt conveyor and submersible pump. The equipment is equipped with a weighing sensor and automatic batching system, which can set each batching weight and realize automatic feeding and full mixing. The process is completely controlled by the auto-weighing system. After the preparation work is completed, press the automatic button to start the automatic working. The mixer is started to mixing. Sand, cement, water and foaming agent are loaded in turn and mixed quickly after reaching the set weight. After the mixing is even, open the discharge door. The mixture flow down into the lower screen of the agitator. The low speed mixing blades are equipped in this agitator. After the mixture completely flow down, close the door and continue the next batch mixing. At the same time, start the hose pump to pump the foam concrete mixture to the work site.LFC1000-H Foam concrete machine supplier

LFC1000-H foam concrete machine is composed of mixer, agitator, foam generator, hose pump, equipped with screw feeder, belt conveyor and submersible pump. The equipment is equipped with a weighing sensor and automatic batching system, which can set each batching weight and realize automatic feeding and full mixing. The process is completely controlled by the auto-weighing system. After the preparation work is completed, press the automatic button to start the automatic working. The mixer is started to mixing. Sand, cement, water and foaming agent are loaded in turn and mixed quickly after reaching the set weight. After the mixing is even, open the discharge door. The mixture flow down into the lower screen of the agitator. The low speed mixing blades are equipped in this agitator. After the mixture completely flow down, close the door and continue the next batch mixing. At the same time, start the hose pump to pump the foam concrete mixture to the work site.LFC1000-H Foam concrete machine supplier -

LF5 foam concrete machine for sale is specially designed for small building or production according to market demand. LF5 foam concrete machine for sale is small in size, light in weight, easy to move and operate, and stable in performance, which can meet the requirements of different project sizes. The machine integrates pumping, foaming and mixing systems into one, which is easy to use.LF5 5m3/h Foam Concrete Machine For Sale

LF5 foam concrete machine for sale is specially designed for small building or production according to market demand. LF5 foam concrete machine for sale is small in size, light in weight, easy to move and operate, and stable in performance, which can meet the requirements of different project sizes. The machine integrates pumping, foaming and mixing systems into one, which is easy to use.LF5 5m3/h Foam Concrete Machine For Sale -

LM2000 concrete foaming machine is one of the high capacity foam concrete mixers. It includes feeding systems, pumping systems, foaming systems and mixing systems. All procedures are program controlled and very labor efficient. The amount of feed, water and foam can be accurately weighed to ensure the quality of the final foamed concrete.LM2000 Concrete Foaming Machine

LM2000 concrete foaming machine is one of the high capacity foam concrete mixers. It includes feeding systems, pumping systems, foaming systems and mixing systems. All procedures are program controlled and very labor efficient. The amount of feed, water and foam can be accurately weighed to ensure the quality of the final foamed concrete.LM2000 Concrete Foaming Machine

.jpg)

.jpg)