Your position:

Home > Products > Foam Concrete Machine

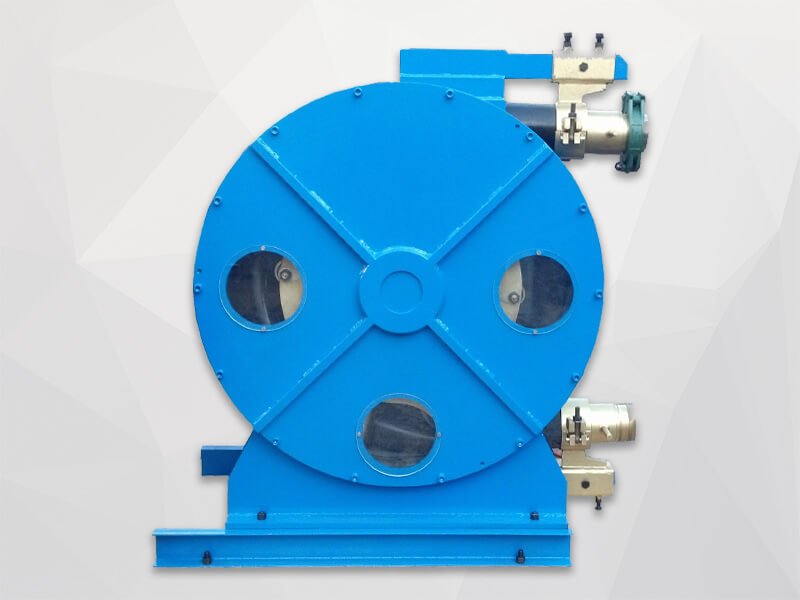

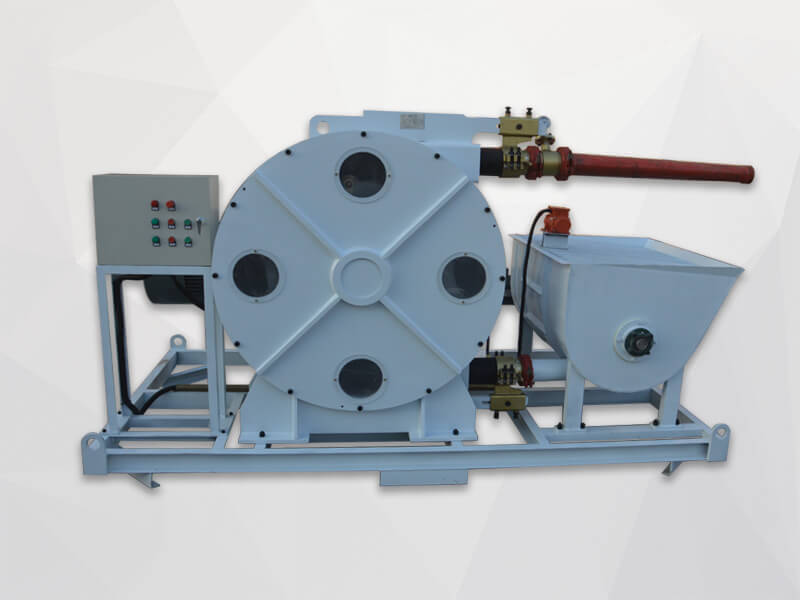

LF20 CLC Making Machine

LF20 CLC brick making machine is a medium-sized foamed concrete brick making machine based on many years of experience, with completely independent intellectual property rights.

LF20

20

21

580

1100

1940*780*1470

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

LF20 CLC making machine is a medium-sized foamed concrete-making machine based on many years of experience, with completely independent intellectual property rights.

LF20 CLC brick making machine includes screw conveyor, mixer, foam generator and foam concrete pump. It adopts advanced control technology to precisely adjust the density of foam cement. It can also meet the production of foam concrete products with different densities, with a capacity of 20m3/h.

LF20 CLC brick making machine includes screw conveyor, mixer, foam generator and foam concrete pump. It adopts advanced control technology to precisely adjust the density of foam cement. It can also meet the production of foam concrete products with different densities, with a capacity of 20m3/h.

Application

LF20 CLC brick making machine has high power, simple operation and convenient movement. It is the first choice machine for making concrete bricks. Besides, it can be applied in many aspects.

1. Sewers and Drains filling

2. Horizontal floor heightening

3. Water tank and fuel tank building

4. Platform filling and mending

5. Garden and rockeries

6. Cellar, basement and arch filling

1. Sewers and Drains filling

2. Horizontal floor heightening

3. Water tank and fuel tank building

4. Platform filling and mending

5. Garden and rockeries

6. Cellar, basement and arch filling

Features

1. LF20 CLC brick making machine is a middle-sized one, designed for bricks production, which is easy to operate and mobile.

2. LF20 CLC brick making machine pumping, foaming and mixing system assembles as a whole, convenient to use;

3. CLC brick making machine has the continuous feeding system and water supply system, with high pumping height and low power requirement.

4. Foam concrete mixer and pump adopts hydraulic system to pump foam concrete, more powerful, can up to 80m vertical pumping distance.

2. LF20 CLC brick making machine pumping, foaming and mixing system assembles as a whole, convenient to use;

3. CLC brick making machine has the continuous feeding system and water supply system, with high pumping height and low power requirement.

4. Foam concrete mixer and pump adopts hydraulic system to pump foam concrete, more powerful, can up to 80m vertical pumping distance.

Product Details

Technical Parameters

| Model | LF20 CLC foam concrete making machine |

| Max. theoretical concrete put(m³/h) | 20 |

| Motor power(kw) | 21 |

| Theoretical vertical conveying height(m) | 80 |

| Theoretical level transmission distance(m) | 500 |

| Mixer tank capacity(L) | 580 |

| Filling height(mm) | 1100 |

| Mixer size(mm) | 1940*780*1470 |

| Feeder size(mm) | 3990*760*830 |

| Main part overall dimension(mm) | 3000*1420*830 |

| Weight of main part(kg) | 1400 |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LM2000 concrete foaming machine is one of the high capacity foam concrete mixers. It includes feeding systems, pumping systems, foaming systems and mixing systems. All procedures are program controlled and very labor efficient. The amount of feed, water and foam can be accurately weighed to ensure the quality of the final foamed concrete.LM2000 Concrete Foaming Machine

LM2000 concrete foaming machine is one of the high capacity foam concrete mixers. It includes feeding systems, pumping systems, foaming systems and mixing systems. All procedures are program controlled and very labor efficient. The amount of feed, water and foam can be accurately weighed to ensure the quality of the final foamed concrete.LM2000 Concrete Foaming Machine -

LF10B aircrete machine for sale is a self-developed patented product. It adopts advanced control technology to continuously and accurately adjust the density of foamed cement. It can also meet the production of foamed concrete products with different densities. The output is 10 cubic meters per hour. Loading operation. LF10B aircrete machine for sale is easy to operate and easy to move. It has continuous feeding and water supply systems, high pumping height and low power requirements.LF10B Aircrete Machine for Sale

LF10B aircrete machine for sale is a self-developed patented product. It adopts advanced control technology to continuously and accurately adjust the density of foamed cement. It can also meet the production of foamed concrete products with different densities. The output is 10 cubic meters per hour. Loading operation. LF10B aircrete machine for sale is easy to operate and easy to move. It has continuous feeding and water supply systems, high pumping height and low power requirements.LF10B Aircrete Machine for Sale -

LF5 foam concrete machine for sale is specially designed for small building or production according to market demand. LF5 foam concrete machine for sale is small in size, light in weight, easy to move and operate, and stable in performance, which can meet the requirements of different project sizes. The machine integrates pumping, foaming and mixing systems into one, which is easy to use.LF5 5m3/h Foam Concrete Machine for Sale

LF5 foam concrete machine for sale is specially designed for small building or production according to market demand. LF5 foam concrete machine for sale is small in size, light in weight, easy to move and operate, and stable in performance, which can meet the requirements of different project sizes. The machine integrates pumping, foaming and mixing systems into one, which is easy to use.LF5 5m3/h Foam Concrete Machine for Sale -

LP30 precast foam cement wall panel machine puts cement and water into a slurry mixing and then mix them in a certain proportion, press them into transmission pipelines through hydraulic cylinder: According to a certain proportion foam mixed with water and then mixed with compressed air by the high-pressure pump: In the pipeline it form the high-densit foam and meticulous, at last form the foam cement with the slurry in the pipeline.LP30 Precast Foam Cement Wall Panel Machine

LP30 precast foam cement wall panel machine puts cement and water into a slurry mixing and then mix them in a certain proportion, press them into transmission pipelines through hydraulic cylinder: According to a certain proportion foam mixed with water and then mixed with compressed air by the high-pressure pump: In the pipeline it form the high-densit foam and meticulous, at last form the foam cement with the slurry in the pipeline.LP30 Precast Foam Cement Wall Panel Machine

.jpg)

.jpg)