Your position:

Home > Products > Foam Concrete Machine

LW30B Automatic CLC foam concrete block cutting machine

LW30B Automatic CLC Foam Concrete Block Cutting Machine is a new design machine in the foam concrete block production line. It is specially used to cut various foam concrete blocks. It is easy to operate and highly efficient.

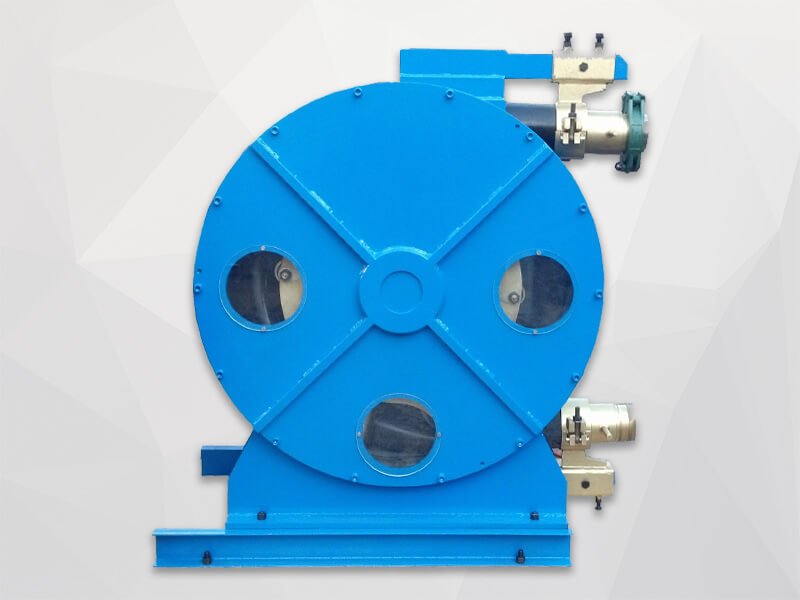

LW30B CLC block wire cutter

2.2kw*1set, 0~560r/min adjusted; 750w*2sets, 0~560r/min adjusted

700mm

1240*1240*225mm

1200*1200*600mm

2160*2060*2280mm

PRODUCTS LIST

HOT products

Inquiry

Introduction

Product Details

Technical data

Cases

Inquiry

Description

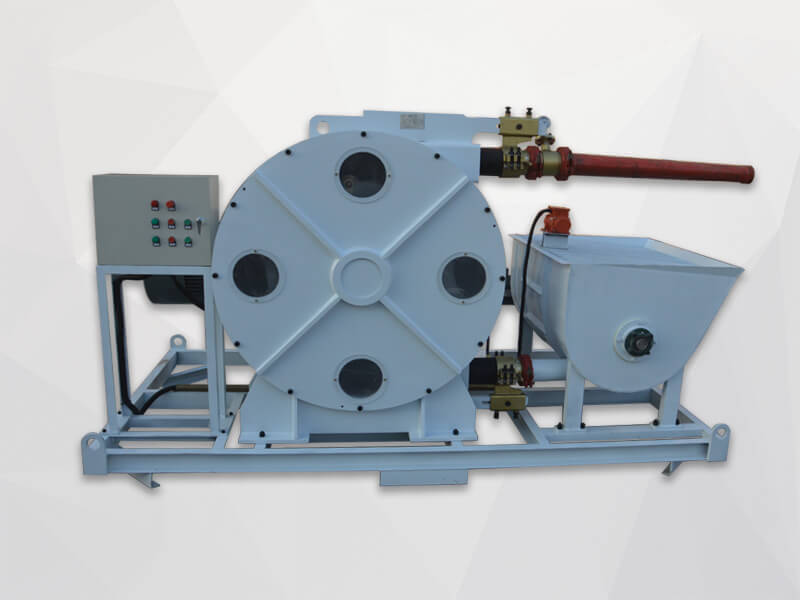

LW30B Automatic CLC foam concrete block cutting machine is a mechanical equipment specially used for cutting foam concrete blocks. Foam concrete block wire cutting machine realizes accurate and efficient cutting of foam concrete blocks through specific cutting technology and equipment design. This kind of concrete block cutting machine is usually equipped with advanced control system and cutting device, which can be adjusted and operated according to different cutting needs.

Working principle of CLC blocks cutting machine:

The working principle of foam concrete block wire cutting machine is mainly based on mechanical cutting and control system. The mechanical cutting part physically cuts the foam concrete blocks through cutting tools such as blades or cables. The control system is responsible for adjusting the cutting parameters, monitoring the cutting process, and ensuring the accuracy and safety of the cutting.

Technical features of CLC wire cutting machine:

High precision: Wire cutting machine for foam concrete block adopts advanced control system and cutting technology, which can achieve high-precision cutting and ensure the flatness and verticality of the cutting surface.

High efficiency: The equipment can quickly complete the cutting task, improve production efficiency and reduce production costs.

Automation: Some foam concrete block wire cutting machines have automation functions, which can automatically adjust the cutting parameters, monitor the cutting process, and automatically complete the cutting task.

Versatility: The equipment is suitable for cutting foam concrete blocks of different specifications and shapes, and can meet a variety of cutting needs.

Cable cutting technology:

Cable cutting technology is a new technology in cutting foam concrete blocks. This technology uses the rotational motion of high-voltage cables to form a rotating blade similar to a lawn mower blade on the foam concrete block, so as to quickly and accurately complete the cutting work. The cable cutter consists of a main machine, guide rails, a transmission system, a control panel and cables, and the CLC brick wire cutting machine is mainly used for cutting vacuum foam concrete blocks, polystyrene foam and other foam materials.

Lead Equipment has specialized in the system of cellular lightweight concrete (CLC) block making machines/ lightweight foamed concrete block making machines for many years, such as foam concrete-making machines, foam concrete mixers, foam concrete pumps, CLC block wire cutting machines, CLC foam concrete molds, mould opening machine, CLC blocks clamp, and so on.

If you want to purchase the lightweight concrete block wire cutting machine separately, please contact us for further information. We also accept OEM.

Commercial terms:

1. Guarantee: 1year

2. Delivery time: within one week once receipt the deposit

3. Terms of payment: t/t

4. Spare parts: steel wirerope 500m

Working principle of CLC blocks cutting machine:

The working principle of foam concrete block wire cutting machine is mainly based on mechanical cutting and control system. The mechanical cutting part physically cuts the foam concrete blocks through cutting tools such as blades or cables. The control system is responsible for adjusting the cutting parameters, monitoring the cutting process, and ensuring the accuracy and safety of the cutting.

Technical features of CLC wire cutting machine:

High precision: Wire cutting machine for foam concrete block adopts advanced control system and cutting technology, which can achieve high-precision cutting and ensure the flatness and verticality of the cutting surface.

High efficiency: The equipment can quickly complete the cutting task, improve production efficiency and reduce production costs.

Automation: Some foam concrete block wire cutting machines have automation functions, which can automatically adjust the cutting parameters, monitor the cutting process, and automatically complete the cutting task.

Versatility: The equipment is suitable for cutting foam concrete blocks of different specifications and shapes, and can meet a variety of cutting needs.

Cable cutting technology:

Cable cutting technology is a new technology in cutting foam concrete blocks. This technology uses the rotational motion of high-voltage cables to form a rotating blade similar to a lawn mower blade on the foam concrete block, so as to quickly and accurately complete the cutting work. The cable cutter consists of a main machine, guide rails, a transmission system, a control panel and cables, and the CLC brick wire cutting machine is mainly used for cutting vacuum foam concrete blocks, polystyrene foam and other foam materials.

Lead Equipment has specialized in the system of cellular lightweight concrete (CLC) block making machines/ lightweight foamed concrete block making machines for many years, such as foam concrete-making machines, foam concrete mixers, foam concrete pumps, CLC block wire cutting machines, CLC foam concrete molds, mould opening machine, CLC blocks clamp, and so on.

If you want to purchase the lightweight concrete block wire cutting machine separately, please contact us for further information. We also accept OEM.

Commercial terms:

1. Guarantee: 1year

2. Delivery time: within one week once receipt the deposit

3. Terms of payment: t/t

4. Spare parts: steel wirerope 500m

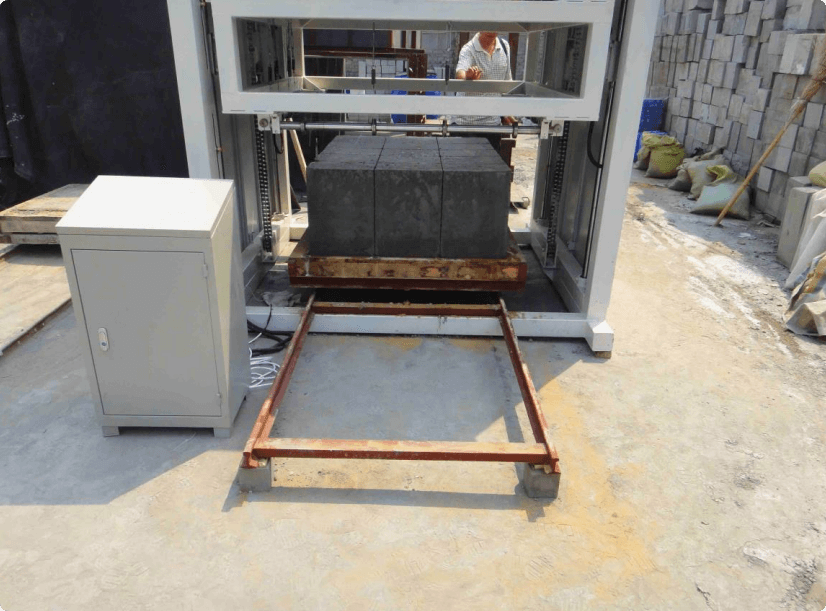

Application

Automatic CLC foam concrete block wire cutting machines are widely used in engineering fields such as construction, roads, and bridges. In the construction field, the equipment can be used to cut foam concrete blocks for the constructionof structures such as walls and floors. In road and bridge engineering, the equipment can be used to cut foam concrete materials for sound insulation, heat insulation and reducing structural weight.

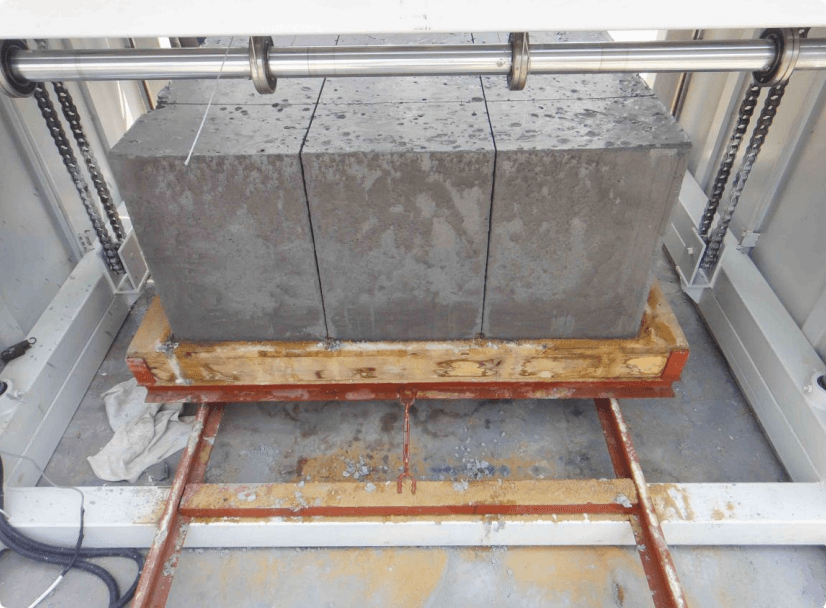

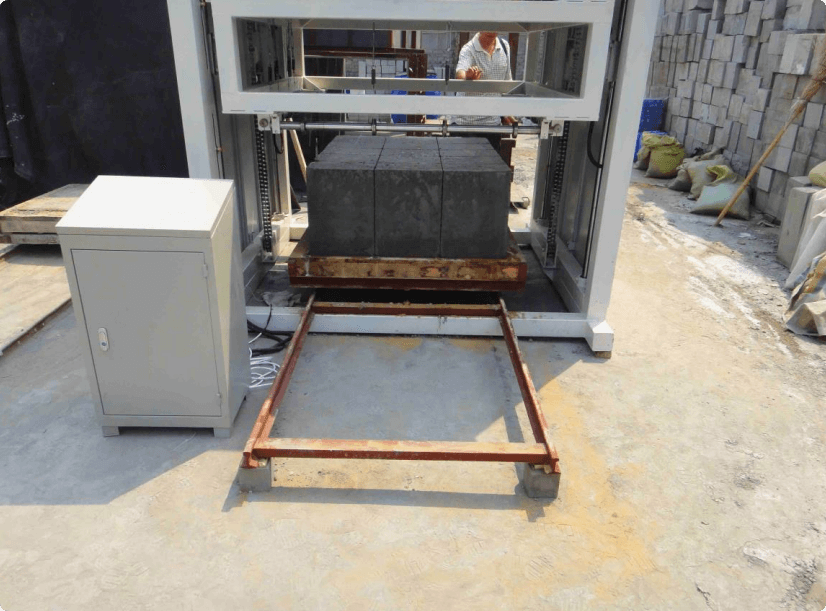

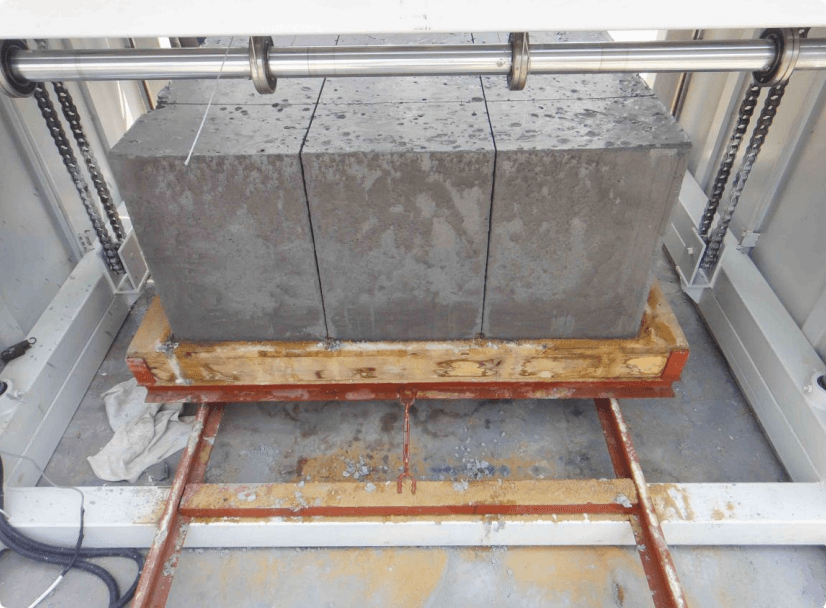

The working site of CLC foam concrete block cutting machine:

The working site of CLC foam concrete block cutting machine:

Features

Main characteristics of CLC block wire cutting machine:

1. The lifting mechanism utilizes a standard automatic braking motor as its power source.

2. The lifting velocity can be customized via a frequency converter for optimal performance.

3. The adjustable block sizes between 100-200-300-400-500-600-700-800-900-1000-1100-1200mm could be adjusted willfully.

4. Each motor is integrated with a speed reducer for efficient operation.

Specialized Attributes of the CLC block cutting machine for sale:

1. Six shafts, each equipped with bearings, minimize friction and extend the lifespan of the rope wire.

2. Both horizontal and vertical cutting methods ensure block stability and produce well-shaped results.

3. The lifting speed, controlled by the chain drive and lifting motor, offers enhanced stability.

4. The cutting frame is equipped with two cutting motors, optimizing space utilization and enhancing the machine's structural robustness.

5. Steel doors replace guard grids, facilitating routine maintenance tasks.

6. A cover added to the top of the cutting machine enhances its aesthetic appeal.

7. The control panel has been upgraded to be compatible with voltage ranges from 380V/50HZ to 460V/50HZ.

1. The lifting mechanism utilizes a standard automatic braking motor as its power source.

2. The lifting velocity can be customized via a frequency converter for optimal performance.

3. The adjustable block sizes between 100-200-300-400-500-600-700-800-900-1000-1100-1200mm could be adjusted willfully.

4. Each motor is integrated with a speed reducer for efficient operation.

Specialized Attributes of the CLC block cutting machine for sale:

1. Six shafts, each equipped with bearings, minimize friction and extend the lifespan of the rope wire.

2. Both horizontal and vertical cutting methods ensure block stability and produce well-shaped results.

3. The lifting speed, controlled by the chain drive and lifting motor, offers enhanced stability.

4. The cutting frame is equipped with two cutting motors, optimizing space utilization and enhancing the machine's structural robustness.

5. Steel doors replace guard grids, facilitating routine maintenance tasks.

6. A cover added to the top of the cutting machine enhances its aesthetic appeal.

7. The control panel has been upgraded to be compatible with voltage ranges from 380V/50HZ to 460V/50HZ.

Product Details

Technical Parameters

Technical Data

| Item | LW30B Wire Cutting Machine |

| Electric Motor (Kw) |

2.2kw*1set,0~560r/min adjusted 750w*2sets,0~560r/min adjusted |

| Effective hoisting height | 700mm |

| Cutting platform size (L*W*H) | 1240*1240*225mm |

| Net cutting size (L*W*H) | 1200*1200*600mm |

| Cutting cycle | 60-180 seconds |

| Overall dimension (L*W*H) | 2160*2060*2280mm |

| Total weight | 1100kg |

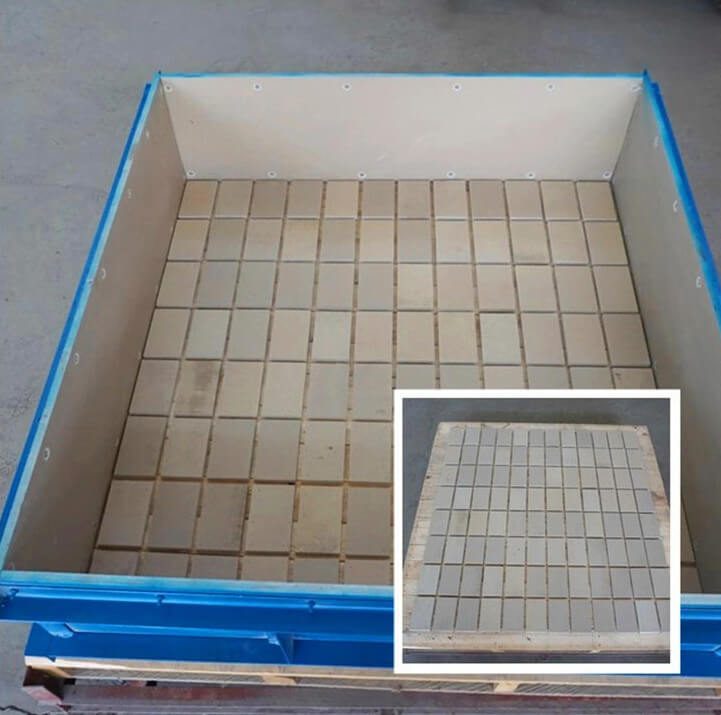

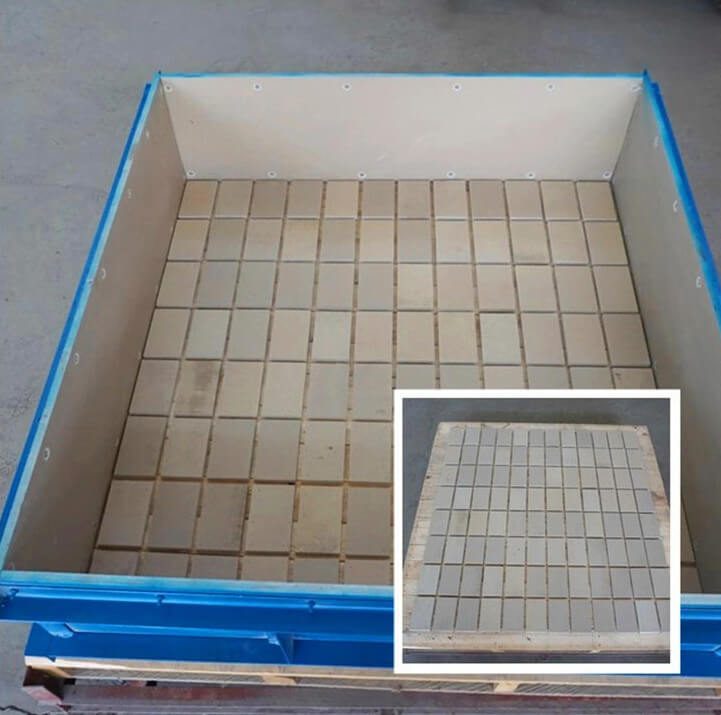

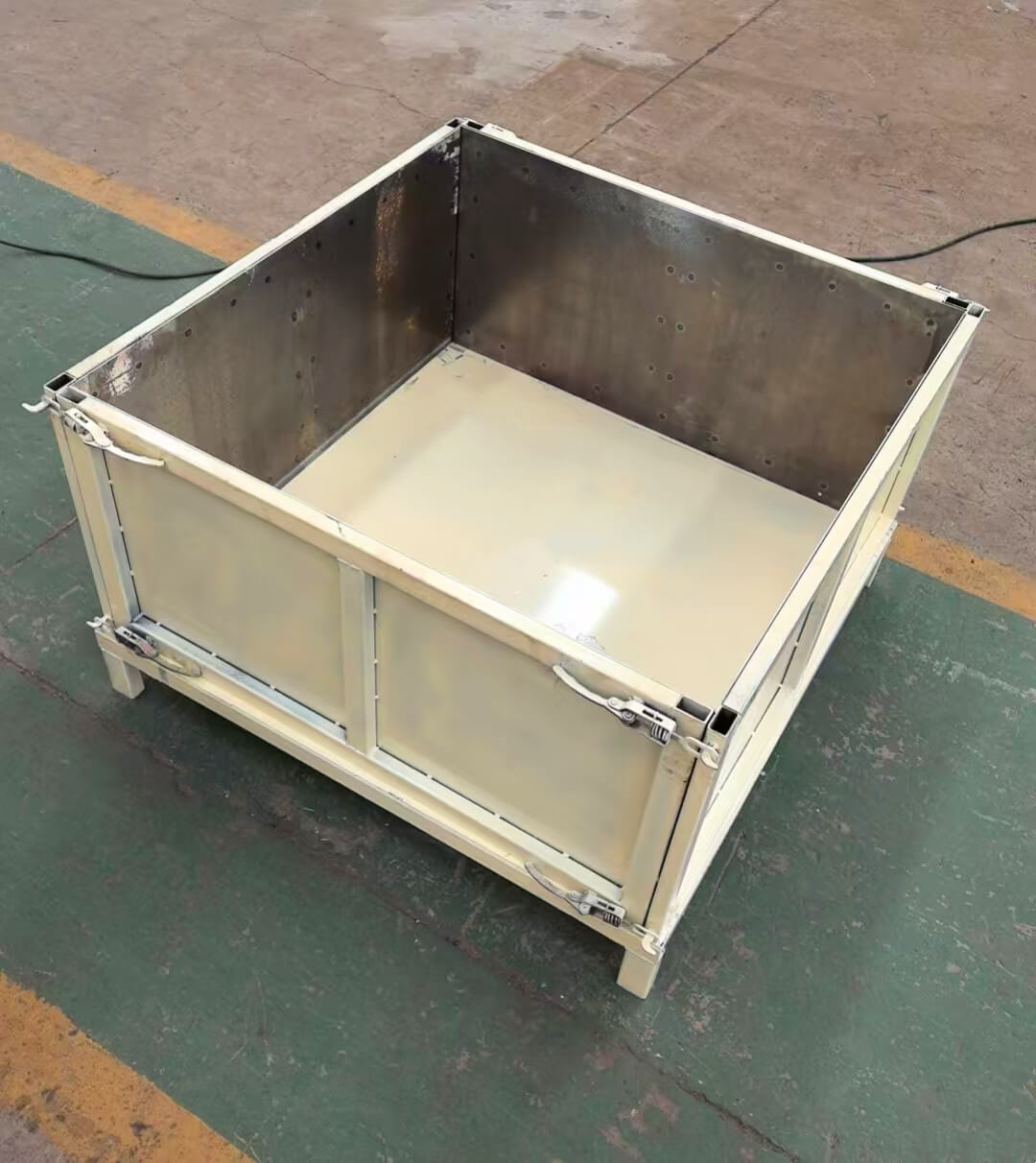

Bloud Mould:

The mould includes the PPC frame and wooden plate trailer.

Overall dimension (L*W*H): 1200*1200*600mm.

Can be customized according to your demands.

| Production capacity | ||

| Mould volume | Block size | Quantity |

| 0.8643M^3 | 600*200*75mm | 96 pcs/mould |

| 0.8643M^3 | 600*200*100mm | 72 pcs/mould |

| 0.8643M^3 | 600*200*150mm | 48 pcs/mould |

| 0.8643M^3 | 600*200*200mm | 36 pcs/mould |

| 0.8643M^3 | 600*200*300mm | 24 pcs/mould |

A complete set of equipment for cutting foam block:

| No. | Name | Qty. | Unit | Remarks |

| 1 | Wire cutting machine | 1 | set | |

| 2 | Hook | 20 | pcs | |

| 3 | Spring | 20 | pcs | |

| 4 | Steel wirerope | 500 | m | |

| 5 | rail | 2 | pcs | 3m/pc |

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

Related products

-

LF5 foam concrete machine for sale is specially designed for small building or production according to market demand. LF5 foam concrete machine for sale is small in size, light in weight, easy to move and operate, and stable in performance, which can meet the requirements of different project sizes. The machine integrates pumping, foaming and mixing systems into one, which is easy to use.LF5 5m3/h Foam Concrete Machine For Sale

LF5 foam concrete machine for sale is specially designed for small building or production according to market demand. LF5 foam concrete machine for sale is small in size, light in weight, easy to move and operate, and stable in performance, which can meet the requirements of different project sizes. The machine integrates pumping, foaming and mixing systems into one, which is easy to use.LF5 5m3/h Foam Concrete Machine For Sale -

LF20 CLC brick making machine is a medium-sized foamed concrete brick making machine based on many years of experience, with completely independent intellectual property rights.LF20 CLC Making Machine

LF20 CLC brick making machine is a medium-sized foamed concrete brick making machine based on many years of experience, with completely independent intellectual property rights.LF20 CLC Making Machine -

LF10B aircrete machine for sale is a self-developed patented product. It adopts advanced control technology to continuously and accurately adjust the density of foamed cement. It can also meet the production of foamed concrete products with different densities. The output is 10 cubic meters per hour. Loading operation. LF10B aircrete machine for sale is easy to operate and easy to move. It has continuous feeding and water supply systems, high pumping height and low power requirements.LF10B Aircrete Machine for Sale

LF10B aircrete machine for sale is a self-developed patented product. It adopts advanced control technology to continuously and accurately adjust the density of foamed cement. It can also meet the production of foamed concrete products with different densities. The output is 10 cubic meters per hour. Loading operation. LF10B aircrete machine for sale is easy to operate and easy to move. It has continuous feeding and water supply systems, high pumping height and low power requirements.LF10B Aircrete Machine for Sale -

LFC1000-H foam concrete machine is composed of mixer, agitator, foam generator, hose pump, equipped with screw feeder, belt conveyor and submersible pump. The equipment is equipped with a weighing sensor and automatic batching system, which can set each batching weight and realize automatic feeding and full mixing. The process is completely controlled by the auto-weighing system. After the preparation work is completed, press the automatic button to start the automatic working. The mixer is started to mixing. Sand, cement, water and foaming agent are loaded in turn and mixed quickly after reaching the set weight. After the mixing is even, open the discharge door. The mixture flow down into the lower screen of the agitator. The low speed mixing blades are equipped in this agitator. After the mixture completely flow down, close the door and continue the next batch mixing. At the same time, start the hose pump to pump the foam concrete mixture to the work site.LFC1000-H Foam concrete machine supplier

LFC1000-H foam concrete machine is composed of mixer, agitator, foam generator, hose pump, equipped with screw feeder, belt conveyor and submersible pump. The equipment is equipped with a weighing sensor and automatic batching system, which can set each batching weight and realize automatic feeding and full mixing. The process is completely controlled by the auto-weighing system. After the preparation work is completed, press the automatic button to start the automatic working. The mixer is started to mixing. Sand, cement, water and foaming agent are loaded in turn and mixed quickly after reaching the set weight. After the mixing is even, open the discharge door. The mixture flow down into the lower screen of the agitator. The low speed mixing blades are equipped in this agitator. After the mixture completely flow down, close the door and continue the next batch mixing. At the same time, start the hose pump to pump the foam concrete mixture to the work site.LFC1000-H Foam concrete machine supplier

.jpg)

.jpg)