Lead Equipment is focus on high-pressure grout pump plant. Now full series of grout plant with different mixer capacity, agitator capacity and pump pressure are provided. Our grout plant with TBM is widely used for backfill in tunnel projects.

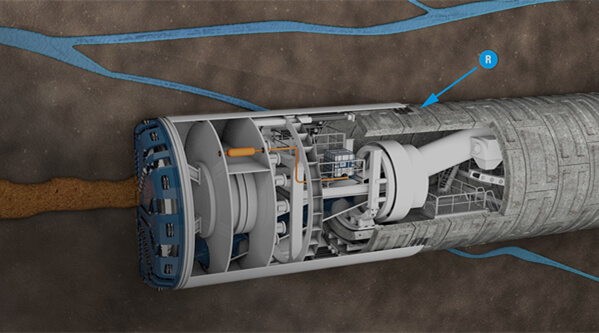

TBM grout plant is including a colloidal grout mixer, grout agitator and a grout pump. Mixer agitator and pump all on one based frame, it could result a continuous mixing and grouting projects. This is necessary for the grouting projects, such as tunneling projects.

Excavation with TBM means that precast concrete segments are installed to form the tunnel, and an annular gap remains between these segments and the ground. The filling of this annulus is a very important requirement as this ensures homogeneous contact with the ground, transfers load from the TBM back-up and also can help to waterproof the tunnel.

Two component injection backfill is prepared by mixing a blend of water/cement, bentonite and retarder (component A) with an accelerator (component B). These get mixed just before the component A is injected through the tailskin and transforms itself from a creamy liquid to a gel in around 10 – 20 seconds. The final mix has comparable compressive strength to that of the surrounding ground and can fill every gap and void before it sets and hardens.

LGP400/700/80PL-E TBM grout mixer with pump is we specially designed for backfill, the high shear grout mixer volume is 400L, agitator volume is 700L, there are two stages for pressure, that is low pressure and high pressure, when at low pressure stage, the pressure is 0-25 bar, grout flow is 0-80L/min, when at high pressure stage, the pressure is 45 bar, flow is 0-58L/min.

The TBM grout plant for back fill has following advantages:

1. Continuous output with small pulse or kicks or jerks.

2. Grouting pressure and flow both could be adjust step-less.

3. High speed vortex mixers ensure mixing evenly and quickly.

4. Grout mixer and agitator switch by using squeeze handle, easy to operate, safe and reliable.

5. The motors with overload protection function.

6. The hydraulic system is with oil temperature overheating protection.

7. Les spare parts make sure the machine with low maintenance costs.

In one word, the TBM grout plant with simple structure, compact size, light weight, easy maintenance etc. features in one.

The capacity of the TBM grout plant should be related to expected grout take. The grout mixer capacity, grout agitator capacity, grout pump flow and pressure. Also power for the mixing grout plants. The TBM grout plant could be an electric motor, diesel engine and air motor. Based on the working site power supply.

For more information about TBM grout mixer with pump for back fill, please email us: sales1@leadcrete.com.

Your position:

Home > News > Product News

TBM grout plant for back fill

date: 2021-12-07

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)