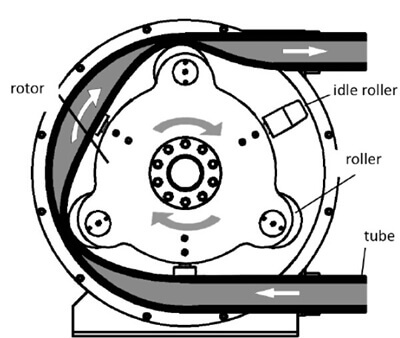

Industrial peristaltic pumps are also called perstaltitic hose pumps, and only squeeze hoses are in contact with materials during work. The rotor drives the roller to rotate to deform the squeezed hose. After the roller rotates, the deformed hose recovers by elasticity. Thus, a negative pressure is generated in the hose, the slurry is sucked in, and discharged from the outlet under the push of the drum, and finally a pressure conveying of the slurry is formed.

Perstaltitic pumps for pumping aluminum oxide slurry are usually mainly composed of pump hoses, rotors, drums, idlers, squeezing hoses and driving devices. The squeeze hose is U-shaped in the pump room. When the rotor drives the drum to rotate, the hose will deform. After the drum rotates, the deformed hose recovers by elasticity. Thus, negative pressure is generated, the slurry is sucked out, and discharged from the outlet under the push of the drum, and finally the pressure transmission of the slurry is formed.

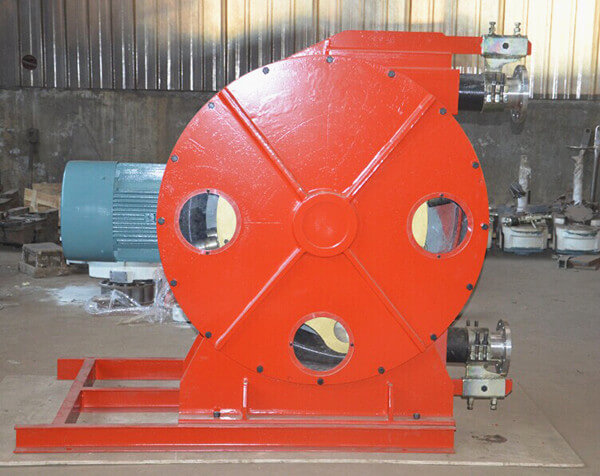

Industrial perstaltitic hose pumps can be used to pump aluminum oxide slurry. Since the pipe is only a spare part, easy to maintain and cost saving, the peristaltic pump has received better feedback from customers.

The working principle of perstaltitic pump for pumping aluminum oxide slurry:

The perstaltitic hose pumps sold have more technical advantages than other pumps, such as:

★ Only the squeeze hose is a vulnerable part, and it is also the only part that comes into contact with the pumped product.

★ It will automatically self-prime when it is turned on, without any special equipment. Only viscous products require overflow suction.

★ The symmetrical design of the pump makes its passage completely reversible

Just in the direction of rotation.

★ Only the pump hose is in contact with the fluid. This eliminates all corrosion problems associated with acid (hydrochloric acid, sulfuric acid, nitric acid...) or alkaline (detergent sodium hydroxide or hypochlorite) products.

★ Elastomer hoses are more wear-resistant than metal surfaces. The low operating speed further reduces the wear caused by the mud.

★ The conveying is carried out in the pump tube, and will not agitate or foam the product. This characteristic combined with low running speed is essential for delicate products or emulsions (latex...).

★ The maximum allowable size of solid particles is 1/3 of the hole diameter of the hose. The size of the soft particles (fruit, meat, fish...) can be the same as the diameter of the hose.

Depending on the output of perstaltitic hose pump, we also have a variety of perstaltitic pumps for pumping aluminum oxide slurry to choose from, so if you need a perstaltitic hose pump for pumping aluminum oxide slurry, please contact sales1@leadcrete.com for more information, without hesitation.

Your position:

Home > News > Product News

Perstaltitic pump for pumping aluminum oxide slurry

date: 2021-11-02

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)