Features of premix refractory concrete mixer:

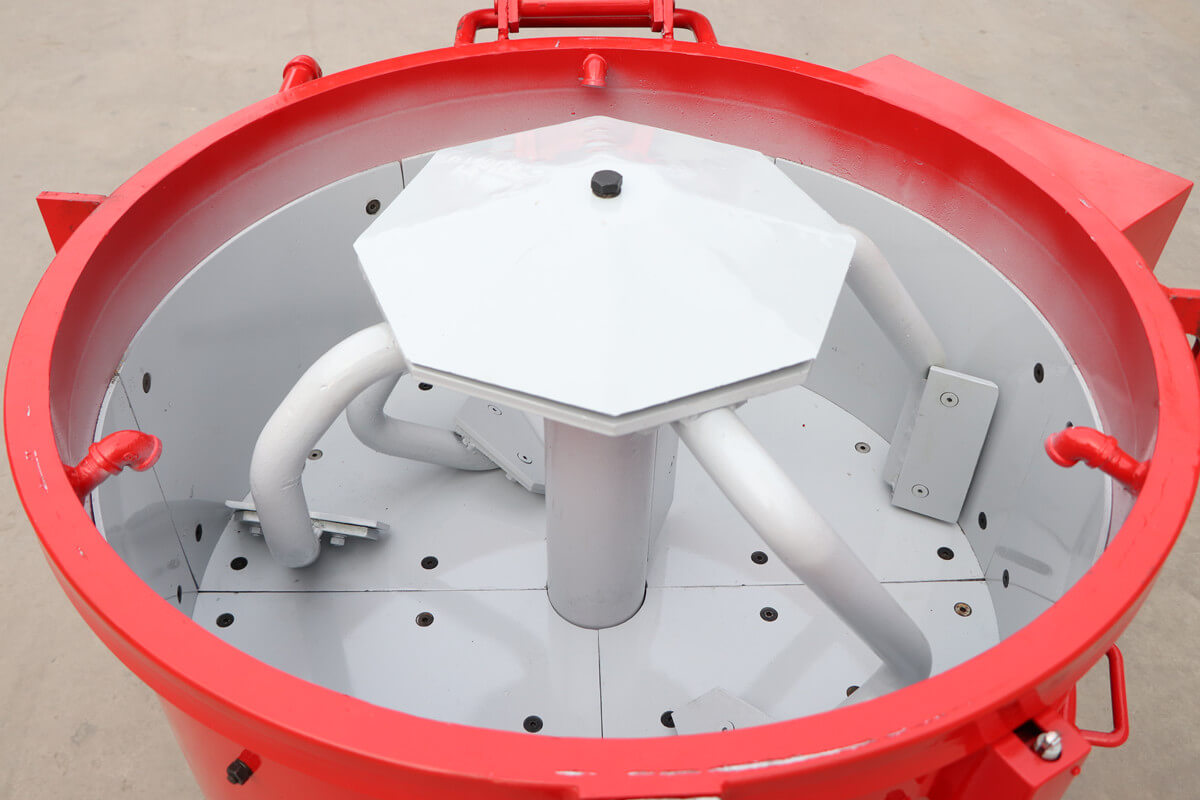

Efficient mixing: The use of advanced mixing technology and design ensures that refractory materials can be evenly mixed and improves product quality.

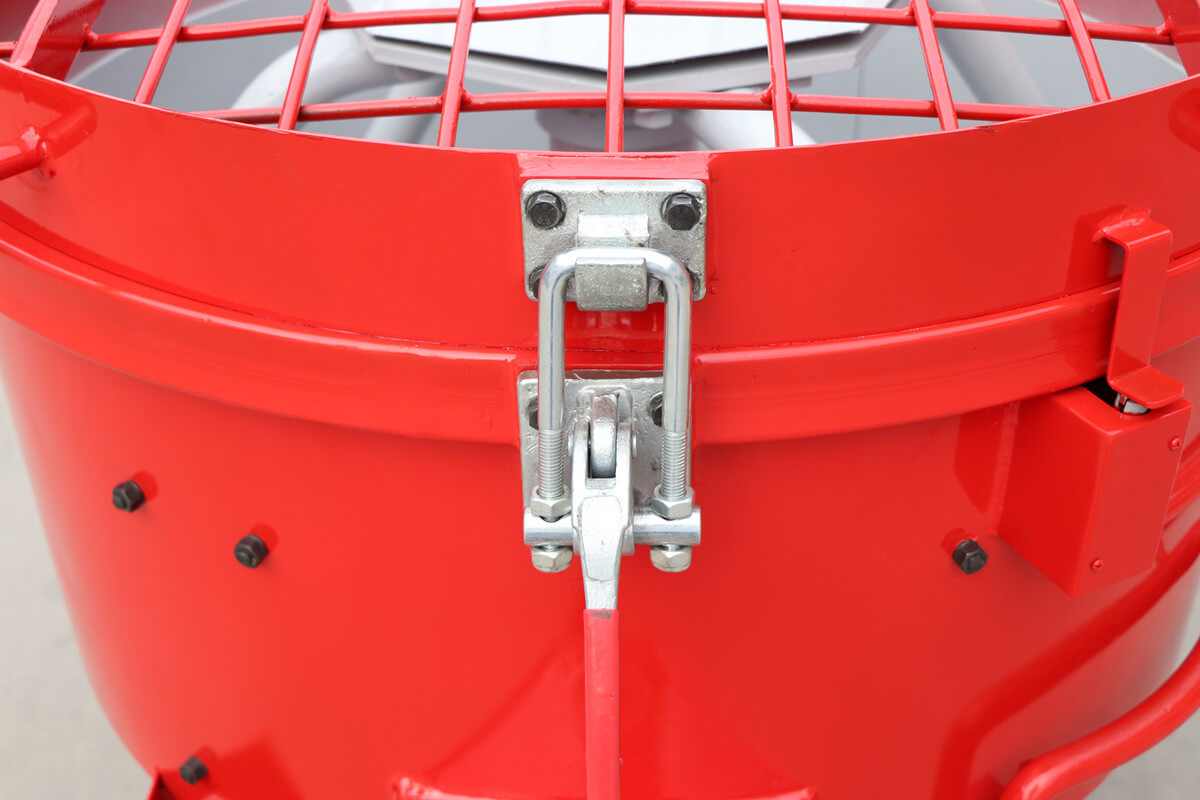

Compact structure: The design is compact and the footprint is small, which is convenient for flexible movement and installation at the construction site or in the factory.

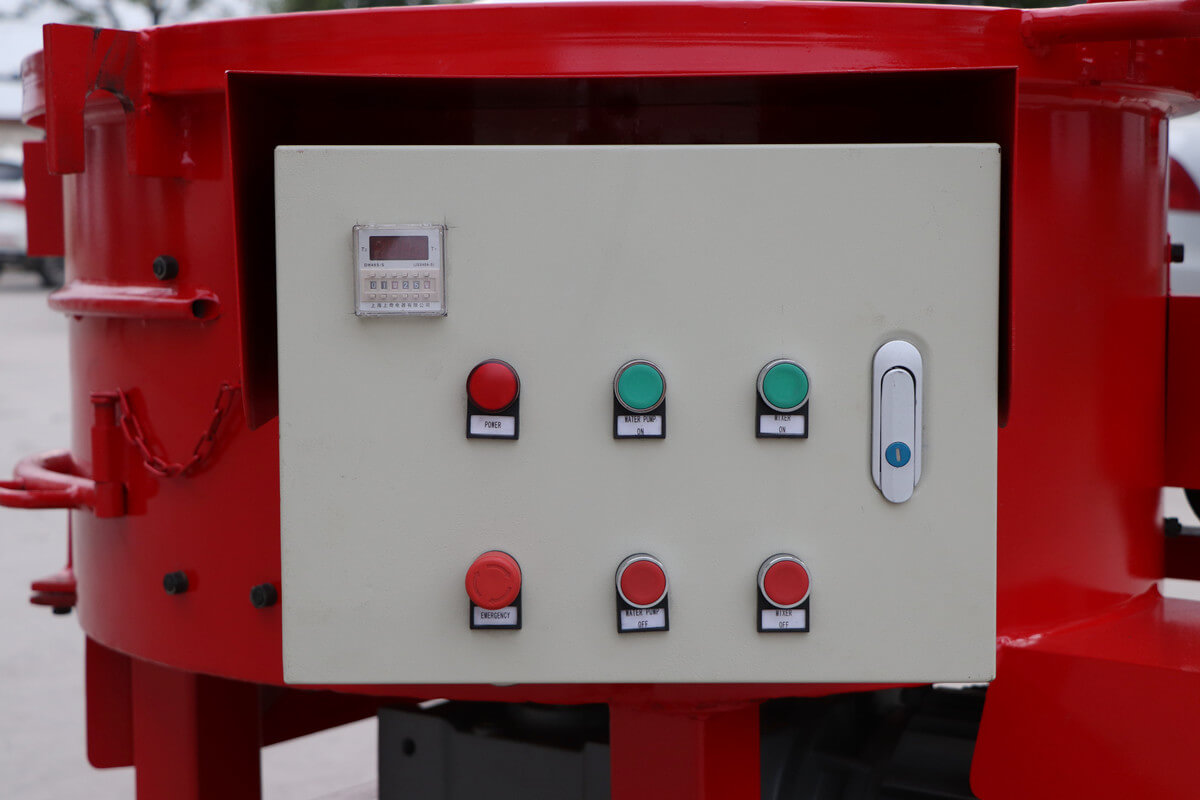

Easy operation: It has a user-friendly operation interface and control system, which is easy to operate and easy to maintain and maintain.

100 kgs of premix refractory concrete mixer is suitable for many occasions, including but not limited to the following aspects:

Refractory material production plant:In the production process of refractory materials (such as refractory bricks, refractory castables, etc.), premixed refractory concrete mixer is used to mix various refractory aggregates, powders, binders and additives to ensure the quality and performance of the products.

Steel smelting and glass manufacturing industries:

These industries usually need to use a large amount of refractory materials to build and maintain their equipment and structures in high-temperature working environments. Premixed refractory concrete mixers can provide these industries with the required high-quality refractory concrete mixtures.

Kiln construction and maintenance:

When building and maintaining various kilns (such as cement kilns, glass kilns, ceramic kilns, etc.), premixed refractory concrete mixers can be used to prepare refractory concrete suitable for different working conditions and requirements.

Heat treatment and chemical equipment:

These refractory concrete mixers usually require high-temperature resistant linings or protective layers, and premixed refractory concrete mixers can provide them with the required refractory material mixtures.

Nuclear power plants and energy facilities:

In nuclear power plants and other energy facilities, some key equipment and structures require a protective layer that is resistant to high temperatures and radiation. Ready-mixed refractory concrete mixers can be used to prepare refractory materials for these special requirements.

Small and medium-sized engineering projects:

For some small and medium-sized engineering projects, especially those that require on-site mixing of refractory materials, ready-mixed refractory concrete mixers provide convenient and efficient solutions.

In summary, the 100kgs refractory concrete mixer has the characteristics of efficient mixing, compact structure, and easy operation, which is suitable for a variety of application scenarios.

Mixers of different capacities are suitable for projects and production needs of different sizes. A 100kgs ready-mixed refractory concrete mixer may be more suitable for small to medium-sized projects or production batches, while a larger capacity of 250kgs, 500kgs, 800kgs, 1000kgs mixing capacity refractory pan mixers may be more suitable for large projects or continuous production. When purchasing, factors such as brand and reputation, mixing efficiency, durability, and ease of operation should be considered. At the same time, regular maintenance and care should be carried out to ensure its normal operation and extend its service life.

If you are interested in our refractory castable pan mixers, please contact us directly at: sales1@leadcrete.com

.jpg)

.jpg)