The intelligent grouting recorder stores and displays all key parameters related to high-quality grouting such as pressure, flow, density, heave, volume and time. It makes it easier to monitor the grouting process in the hole, improving the quality of operations and improving overall site efficiency.

Through this intelligent grouting recorder, all parameters can be displayed on the screen in real-time as the grouting operation progresses. At the same time, the sensor data will be automatically saved, and various grouting curves, charts and reports will be formed through intelligent programs.

An grouting recorder is suitable for a series of grouting processes such as WSS grouting, curtain grouting, and road maintenance grouting.

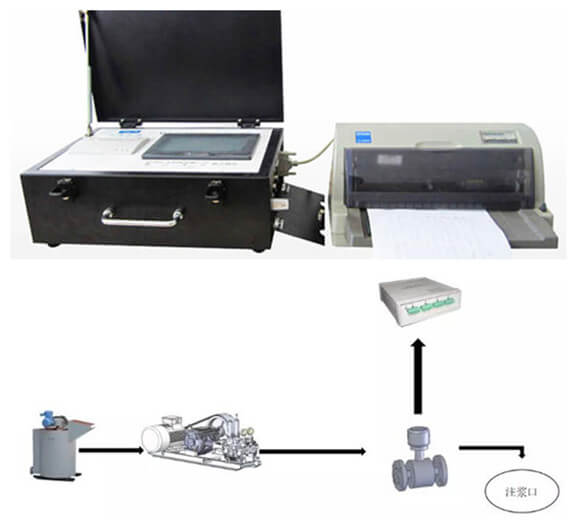

The integrated data acquisition instrument and analysis intelligent grouting recorder is integrated, and high-standard data acquisition instruments are selected to ensure the reliability, authenticity and accuracy of the data. The integrated design makes the detection station easy to move, with simple interface and easy operation.

The intelligent grouting recorder is equipped with Internet remote communication equipment, parameters such as instantaneous and cumulative grouting volume and pressure value can be sent to the network platform, and data supervision and inspection can be carried out through computer Internet access and mobile APP.

According to customer requirements, all parameters can be collected for a single hole and two holes at the same time, and the channel hole number, flow rate, pressure, cumulative grouting amount, instantaneous grouting amount and other information are displayed on the same screen, which is convenient for viewing and has a complete data monitoring function.

(1) In terms of principle, according to the pulse nature of the reciprocating grouting pump, our company's intelligent grouting recorder increases the data collection frequency to 10ms/time, and uses the principles of calculus to process the data to obtain the Data such as grouting speed, cumulative grouting volume, grouting pressure, etc., ensure the reliability, accuracy and authenticity of data processing.

(2) In terms of basic measuring instruments, our company has optimized the electrode and lining of the electromagnetic flowmeter after many discussions with the relevant technical personnel of the electromagnetic flowmeter. According to the characteristics of the mud, it can be configured with low corrosion, strong wear or strong Corrosion, low wear electrodes and liners. In addition, we have also optimized the connection method of the flowmeter and related pipelines to ensure the accuracy and reliability of the original data collection.

(3) In terms of structure, the intelligent grouting recorder developed by the company integrates an electromagnetic flowmeter, grouting recorder and pressure sensor into one, which can be moved as a whole (as shown in the figure below), which protects the electromagnetic flowmeter and other precision instruments. Guarantees accuracy and avoids the tediousness of dragging pipelines on site.

(4) In terms of communication, our company creatively uses remote communication equipment on the intelligent grouting recorder, which can send raw data such as instantaneous flow and cumulative grouting volume to the network platform, and can conduct data supervision through computer Internet access or mobile APP. Inspection of. That is, people are not at the construction site, but also can grasp the site grouting construction status in real-time. In addition, with the equipment of remote communication equipment, our company's technicians can remotely optimize and set the program to ensure after-sales service.

(5) In terms of safety, our company's monitoring station has set up multiple alarms. When the grouting parameters are abnormal, the construction site will send an alarm through the touch screen, and can remotely send an alarm through mobile phone information and phone calls to ensure that every relevant engineer is notified. Email address: sales1@leadcrete.com

Your position:

Home > News > Product News

Intelligent grouting recorder for sale

date: 2022-05-12

Intelligent fluid monitoring station

2022-05-08

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)