Industrial squeeze hose peristaltic pump have a very wide range of uses. It could be widely used in many projects, such as: architecture, underground construction, petrochemical industry, metallurgy, food industry, ceramic, mining, water treatment, hydrocarbon sludge pumping etc.

Working principle of industrial squeeze hose peristaltic pump:

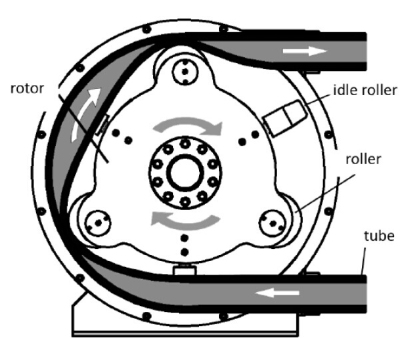

Squeeze hose peristaltic pump are mainly composed of pump house, rotor, roller, idler roller, squeeze tube, hopper, and driving device. The squeezed hose in the pump house is U-shaped. When the rotor drives the drum to rotate, the hose is deformed. After the roller rotates, the deformed hose recovers by elasticity. Thus, a negative pressure is generated in the hose, the slurry is sucked in, and discharged from the outlet under the push of the roller, and finally a pressure conveying of the slurry is formed.

We have industrial squeeze hose peristaltic pumps with different working pressure and output. The working pressure is from 10bar to 26bar, and the output is from 14m3/h to 54m3/h. If customers have any demands, we could provide customized service.

Squeeze hose pump selection instructions:

1. When the process conditions for the intermittent production and no quantitative requirements, the industrial squeeze hose peristaltic pump rated flow can be greater than the actual need for traffic.

2. When the process conditions for continuous production, the actual flow rate should be consistent with the industrial squeeze hose peristaltic pump rated flow. If the required flow can be adjusted, you can choose with the frequency control squeeze hose pump.

3. The rated pressure of the squeeze hose pump refers to the working pressure of the squeeze hose pump under the power motor. The actual working pressure of the squeeze hose peristaltic pump is determined by the loss of the squeeze hose peristaltic pump's own system and pipeline resistance. Therefore, when designing, the actual working pressure in the system will be less than the rated pressure of the hose pump. If the actual working pressure is different from the rated pressure of the hose pump, the motor can be reconfigured.

Maintenance of squeeze hose peristaltic pump:

The rubber hose should be replaced in time according to the frequency of use of the specific pump during use. When the hose breaks and the liquid seeps from the hose and flows into the roller of the pump head, the pump head should be disassembled and cleaned in time to avoid weathering and solidification in the gap of the roller to avoid jamming of the pump head. If the liquid is highly corrosive, please choose a corrosion-resistant hose to avoid damage to the pump.

Contact us for industrial squeeze hose peristaltic pump price:

If you are interested in our industrial squeeze hose peristaltic pump, we will recommend a suitable hose pump for you. Please help us to confirm the following points:

1. What is the project with our peristaltic pump, is it for pumping concrete or others?

2. What is the pressure and output you require?

3. What is the local voltage you require? Is 380V, 50Hz OK for you?

4. What is Max aggregate size in the slurry?

You can send your requirements to our email, email address: sales1@leadcrete.com.

Your position:

Home > News > Product News

Industrial squeeze hose peristaltic pump for sale

date: 2021-12-24

How to buy a hydroseeder?

2021-12-29

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)