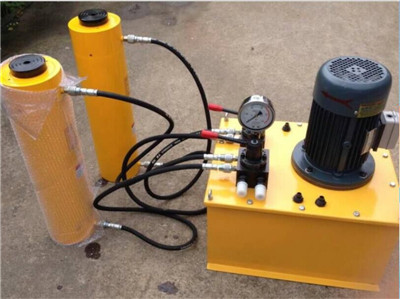

Hydraulic ram cylinder for sale

When lifting a large object, people need to find multiple support points under the weight to place multiple jacks, and then lift the weight synchronously. Especially when the center of gravity of the weight is not at the center, or the weight is in an irregular shape, in order to prevent the weight from being out of synchronization during the lifting process, and thus causing eccentric loading, strict requirements for the synchronized hydraulic ram cylinder are required. We are hydraulic ram cylinder manufacturer and supplier for more than 20 years.

In order to enable multiple hydraulic jacks to be synchronously lifted, we must first ensure that the hydraulic jacks of the same type are used. Zhengzhou leadcrete hydraulic ram cylinders are used for the lifting of bridges, with the use of servo jacks to achieve safe lifting.

However, how should we choose the right hydraulic ram cylinder for us?

1. Tonnage: confirm the required force (tonnage). The recommended hydraulic jack tonnage is 20% higher than the load.

2. Body height and stroke: According to the requirements of working conditions, select the appropriate body height and the required stroke.

3. Frequency of use: According to the requirements of working conditions, distinguish between maintenance level and industrial level. If it is used for production or hydraulic jacks with high frequency, please specify.

4. High temperature or anti-corrosion requirements: According to the actual working conditions, high temperature or anti-corrosion requirements are proposed. Our company will adopt special surface treatment methods and special material seals.

According to different occasions, we choose different solutions.

1. The jack-up plan for lowest hydraulic ram cylinder price

Use a distribution valve to divert the flow of the electric pump to multiple jacks. During the jacking process, it is found that the speed of a certain jack is faster than that of other jacks, then the distribution valve connected to the jack is adjusted to reduce the flow supply to the jack, so that the jack speed becomes slower and achieves synchronization with other jacks. purpose.

During the operation, we need to keep observing the jacking of each jack, and constantly control the flow of the distribution valve through the observation results. The disadvantage of this use is that the accuracy is not high, it needs human control, and it is slightly inattentive, which is prone to misoperation or misjudgment. Therefore, we generally use this method to lift some heavy objects that do not require high accuracy.

Second, the single point control, multi-point cooperation synchronous lifting scheme.

One pump controls one jack, and the pump models are the same. Arrangement of several points to lift, you need several sets of such configurations. Each person needs to be controlled.

Because the same jack and pump are used, the same flow rate and the same lifting speed are provided to the same jack in the same time.The disadvantage is that it is operated by multiple people and is very cooperative. There is a mistake and it is easy to fail. Not easy to control.

If you want to customize a hydraulic ram cylinder suitable for this project, please click on the website to learn more

Your position:

Home > News > Product News

Hydraulic ram cylinder for sale

date: 2020-06-05

Hose pump used in paper making

2020-06-06

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)