diesel powered gunite machine,gunite machine South Africa,diesel powered gunite machine South Africa

Diesel powered gunite machine also named concrete guniting machine, mainly used for dry-mix concrete and damp-mix concrete spraying operation. It has some obvious advantages such as advanced technology, perfect structure, stable performance, convenient operation and longevity of service etc. It is widely used for concrete pump spraying working in building, mining, tunnel, culvert, subway, hydropower engineering, underground excavation engineering, swimming pool building, slope protection etc.

Diesel powered gunite machine South Africa is the most ideal device for the concrete anchor spray construction, dry spray and moist spray. And diesel powered gunite machine be widely used for the anchor spray supporting construction in tunnel, culvert and underground projects. The accelerating admixture conveying system in the machine is independent measured precisely by standard metering pump which is freely adjusted.

Gunite machine South Africa has the following advantages:

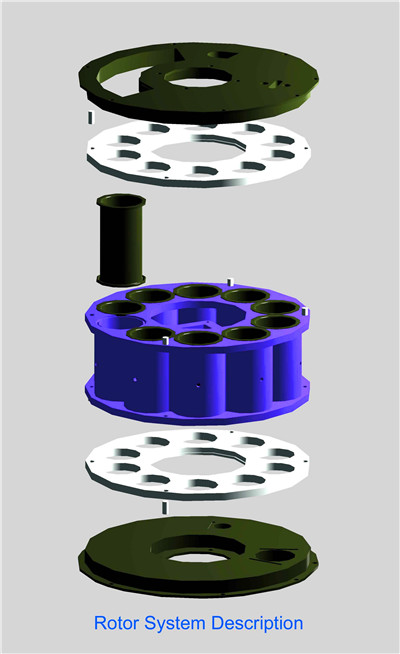

High effective concrete spraying working, Easy operation, Stable performance; Rotor Disk: There are two rotor disks on the opposite sides of rotor, it is made of high-qualified alloy steel and can handle concrete more than 4000m3 during its working Period. Rubber Sealing Plate: There are two plates upper and lower. Both of the upper and lower plates are made of anti-abrasive special rubber and can handle concrete 300-400m3 during its working period. Clamping Device: By this device, the force is acted through the screws and cylindrical springs, which works as elastic auto-clamping device. Tight clamping by the turnover frame floating can provide a constantly uniform pressure at the sealing surfaces with a high tightening effect and low dust emission, and can avoid rubber plate over-worn, too. Thin flow conveying method with vortex flow, so the spraying flow is even, continuous and steady, to improve the shotcrete quality.

The wet mixing method of the concrete dry gunite machine is a method in which the mixed concrete is pumped to a nozzle through a grouting pump, and then compressed air is used for spray irrigation. The concrete dry gunite machine has the significant advantages of less operating dust, less rebound of spraying, protecting the working environment, saving raw materials, improving the quality of spray coating, etc., and convenient operation and maintenance.

Diesel gunite machine is a kind of spraying machine like mortar spraying machine which works by using compressed air to continuously transport concrete along the gunite machine hose and spray it to the construction surface by a shotcrete nozzle. Gunite machine is well received by market because it high efficiency, low coast, easy operation, and wide application. You can use the diesel powered gunite machine in tunnel, mining, retaining wall, underground project, and some other preventive construction projects.

.jpg)

.jpg)