The colloidal grout mixer used for post tensioning uses high shear cement particles instead of centrifugal pumps to simulate shear. The pumping action of mixer can transfer the mixed slurry from mixer to agitator tank quickly. No additional slurry pumps are required. The unique design of the colloidal grout mixer ensures that the mixer is very easy to clean and there is no reason for the operator to leave the grout in the hose, etc. to dry.

Colloidal grout mixer used for post tensioning, tunnels, shafts and mining. It is also used in the following areas:

1. Civil Engineering - dam, tunnel, subway, mine, soil nailing wall, curtain wall, anchor rod, cable trench, bolt grouting.

2. Building structure - building and bridge repair, foundation reinforcement, slope support, soil compaction, terraced grouting.

3. Engineering - grouting and reinforcement of underwater foundation, offshore platform and coastal foundation.

4. Mine application - roadway reinforcement, backfilling, waterproof grouting,

5. Geotechnical engineering - deep well casing, monitoring well, well sealing and abandoned well,

6. Acting as grouting plant in pipe jacking machine,

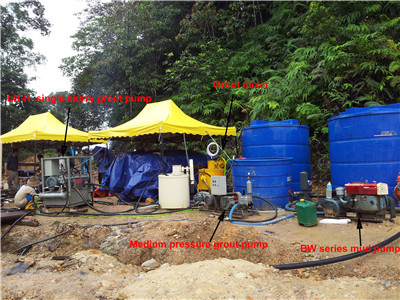

Grouting pump can be used for tunnel excavation and maintenance, mine engineering, dam construction, foundation treatment of bridges and high-rise buildings, and pressure grouting of various underground buildings.

Advantages of colloidal grouting mixer:

1. The tank body is made of thickened plates, which is more reliable and has a longer service life;

2. The whole stamping structure of tank bottom;

3. Special weld treatment of colloidal grout mixer used for tunnels;

4. IP55 100% new motor;

5. The electric control box is made of thickened plate and standard Schneider electrical components;

6. Special design pump sealing structure of colloidal grout mixer used for shafts and mining;

7. After sandblasting, spray paint, beautiful appearance.

For more information on grouting equipment, please email us: sales@leadcrete.com

.jpg)

.jpg)