The foam concrete machine can make the foaming agent into foam according to a certain concentration. It can also be regarded as a foaming machine, which is equivalent to mixing the foaming agent aqueous solution with air to make bubbles, and foaming concrete. It is mainly foam, so the cement foaming machine has become the main equipment for making foamed concrete.

Under the action of the foaming agent and the China foam block machine, the foaming machine forms a foamed concrete shape after mixing with the cement. There are dense air bubbles inside, which have strong stability and are not easy to defoam. The pores are formed after the concrete is dried.

Cement is mixed into the foam, and a large amount of cement solid particles adhere to the liquid film wall of the foam, which makes the liquid film thicker and the toughness of the liquid film is strengthened. The stability of the foam slurry mixture is further improved. The bubble is not easy due to the weight of the slurry. Deformation or defoaming, the next step is the foam stabilization process. The important thing is the setting and hardening process of cement. After curing, the concrete becomes a solid foam concrete with pore walls.

It is precisely this feature of China foam concrete machine that makes foam concrete light in weight and has the effect of thermal insulation. Cement foaming machine has a wide range of uses. The foaming agent can be made into a uniform and fine foam, and then the foam and concrete are mixed to form foamed cement after coagulation. The use of foaming cement is more extensive. Now many of them are used for cast-in-situ concrete insulation, foam concrete lightweight wall panels, prefabricated processing of fire door cores, and floor heating mortars. Fields such as construction.

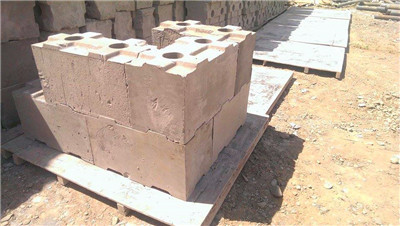

The foamed cement board made by foam concrete machine from China is a new type of fire-proof and heat-insulating energy-saving material. It uses special cement and fly ash as raw materials, adds foaming agents, fibers, etc. and stirs it to foam. The advantages of heat insulation, and the characteristics of light weight, compressive strength, environmental protection and energy saving.

The foam concrete produced by the foaming machine can be used for roof insulation construction, floor heating mortar filling, prefabricated insulation blocks, and wall-filled foam concrete. It is widely used.

So if you want to produce the foam concrete or foam concrete products, such as, foam concrete blocks, foam concrete wall panels, you can contact us. We can provide foam concrete machine, foam agent, foam concrete block moulds and lightweight wall panels machines to you.

Your position:

Home > News > Product News

Foam concrete machine from China

date: 2020-06-15

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)