What are the benefits of foam concrete?

Since foamed concrete does not settle, it does not need to be compacted. It is also free-flowing and self-leveling, so it can expand to fill gaps, thereby reducing human pressure and speeding up work.

Coupled with the fact that foam concrete requires almost no maintenance once in place, making it a very cost-effective material.

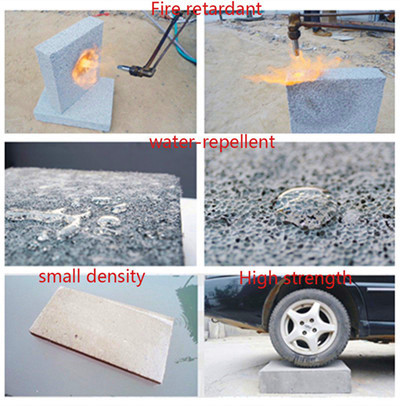

The result of solidification is much lighter than concrete, so it will not crush anything underneath it when a significant lateral load is applied, although it is strong and durable enough for most applications where concrete is normally used.

Our LD2000 foam concrete mixer can mix the concrete evenly and greatly avoid foam breakage. As a new type of cement mixer, LD2000 foam concrete mixer has the characteristics of fast mixing speed, short mixing time, low foam loss, uniform mixing, etc., which can ensure the high quality and high productivity of foam concrete.

Main applications of foam concrete:

Formwork concrete has become a popular building material because of its environmental protection and low cost. It has excellent waterproof and antifreeze performance, and provides a high level of sound and heat insulation performance.

The main applications are as follows:

Blocks: Blocks and panels can be used for partitions and load-bearing walls. They can be made in almost any size.

Floor: Foamed concrete can be used on the floor to form a flat surface on uneven ground and improve the level of the floor.

Roof insulation: Foam concrete is widely used for roof insulation and making slopes on flat roofs. It has good thermal insulation properties, and because it is lightweight foam concrete, it will not impose a large load on the building.

Our foam concrete machine is an integrated foam concrete machine with perfect performance to meet all the above construction requirements.

Your position:

Home > News > Product News

Benefits of foam concrete

date: 2021-06-26

Foam concrete making machine for sale

2021-06-24

Plastering pump for building maintenance

2021-07-05

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)