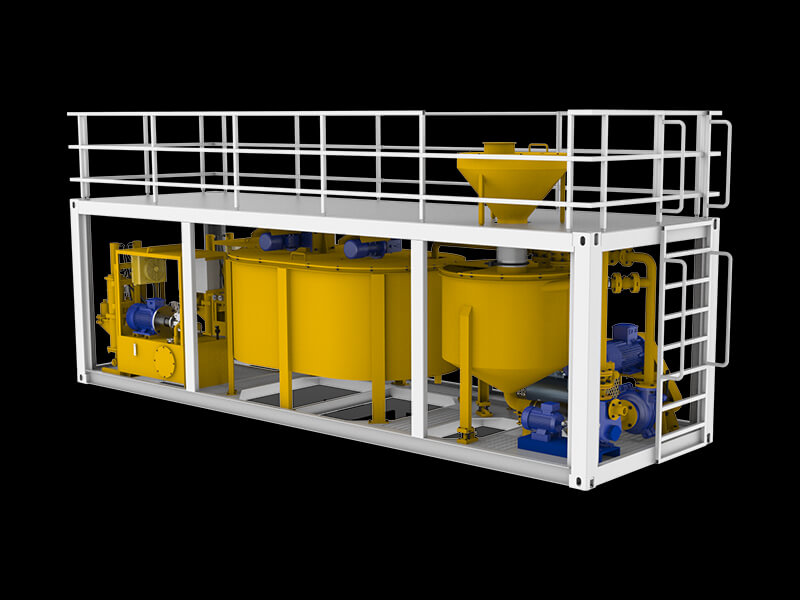

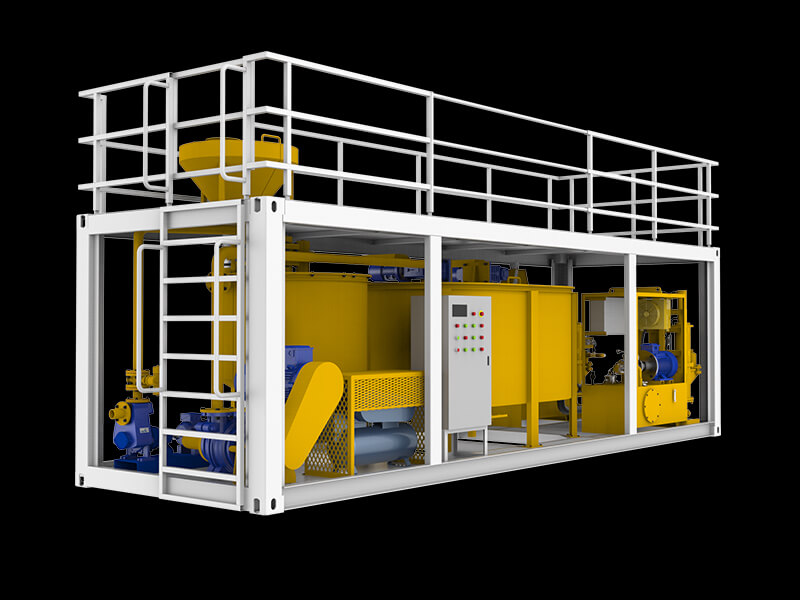

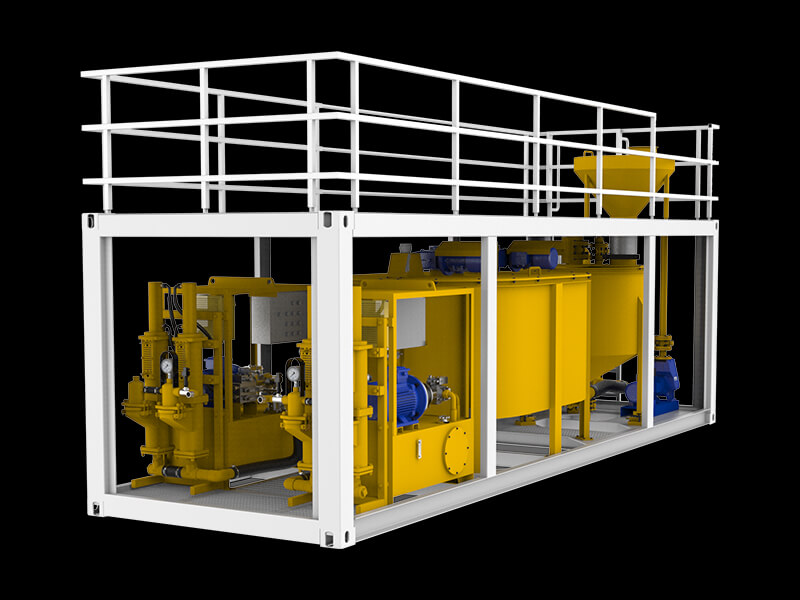

We can customize automatic grout pumping station systems of different sizes for you according to your needs.

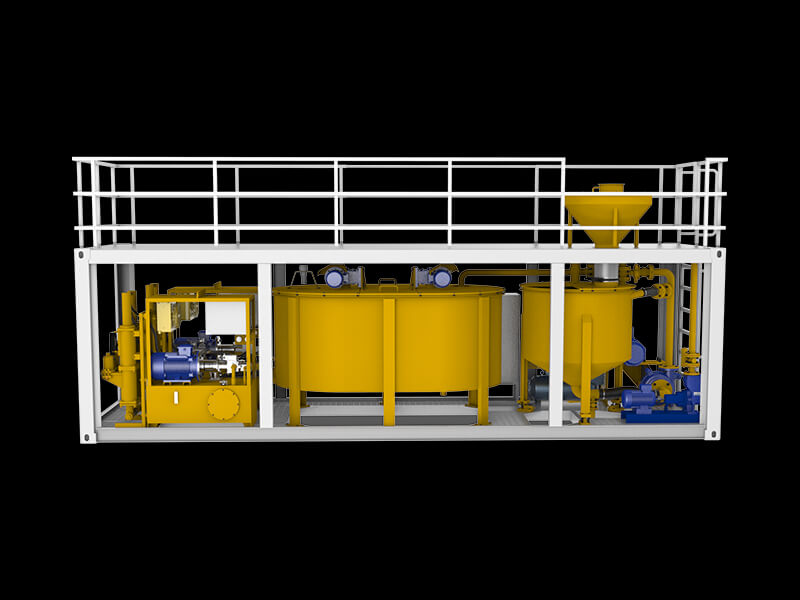

• The continuous mass transfer between the two zones ensures the maximum possible homogeneity of the mixture.• Minimal sedimentation of the mixture.

• High mixing capacity due to short mixing time.

• Lowest possible use of raw materials.

• Operator cabin with fully automatic control panel board.

Advantages of container-type automatic grout station system:

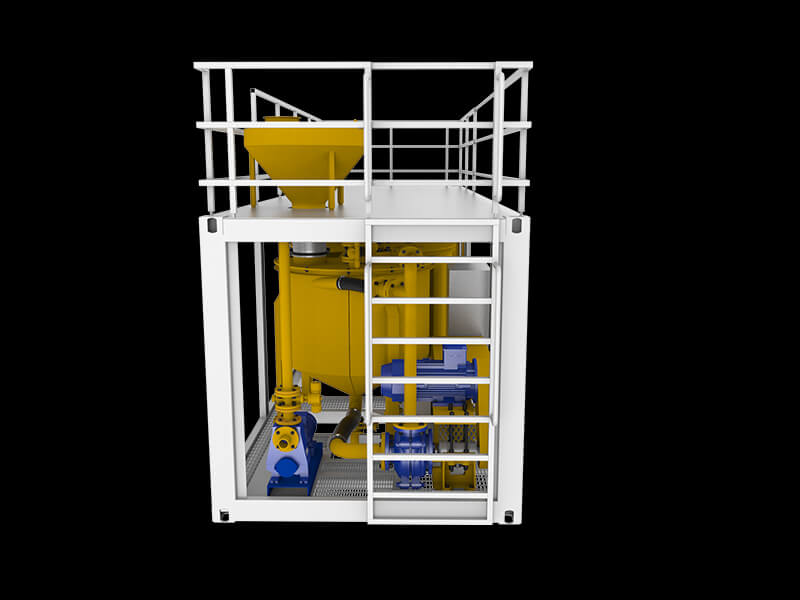

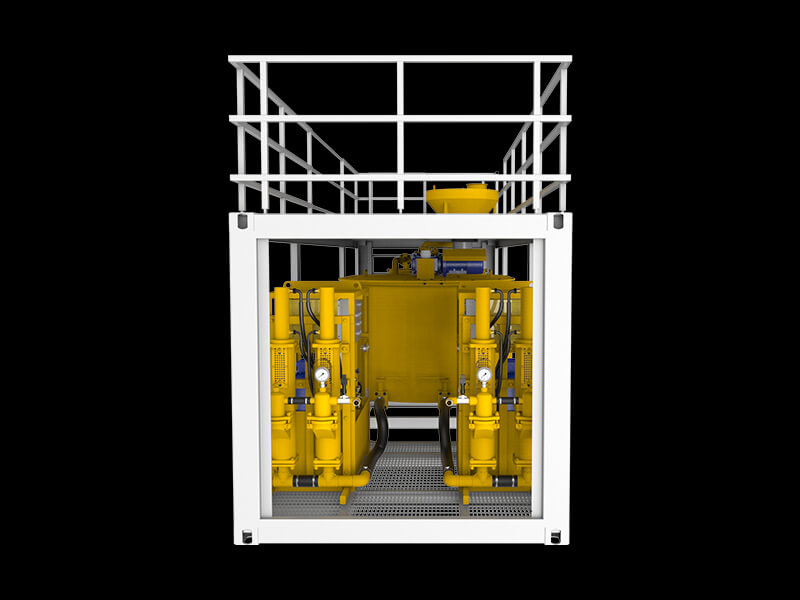

* High-speed colloidal grout mixer* Main pipeline valves are all pneumatic valves

* Mixture, cycling pump, and agitator have automatic cleaning function

* Cement can be added by cement silo or screw feeder automatically

* The preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid component

* Two modes of operation: fully automatic mode and manual mode

* Easy to operate and maintain

* Up to 5mm particle size

* Equipped with some ceiling lamps, for illuminating the different working areas.

* Can be placed directly in the 20ft cabinet

Automatic grout pumping station system application:

1. Drilling2. Dam applications

3. Cavity filling

4. Tunnel applications

5. Anchor injection

6. Concreting

7. Jet grouting

8. Bottom injection

If you need a container type automatic grout pumping station system for such an application, you can contact us directly and tell us your requirements. We will send you a suitable quotation as soon as possible. Email address: sales1@leadcrete.com

.jpg)

.jpg)