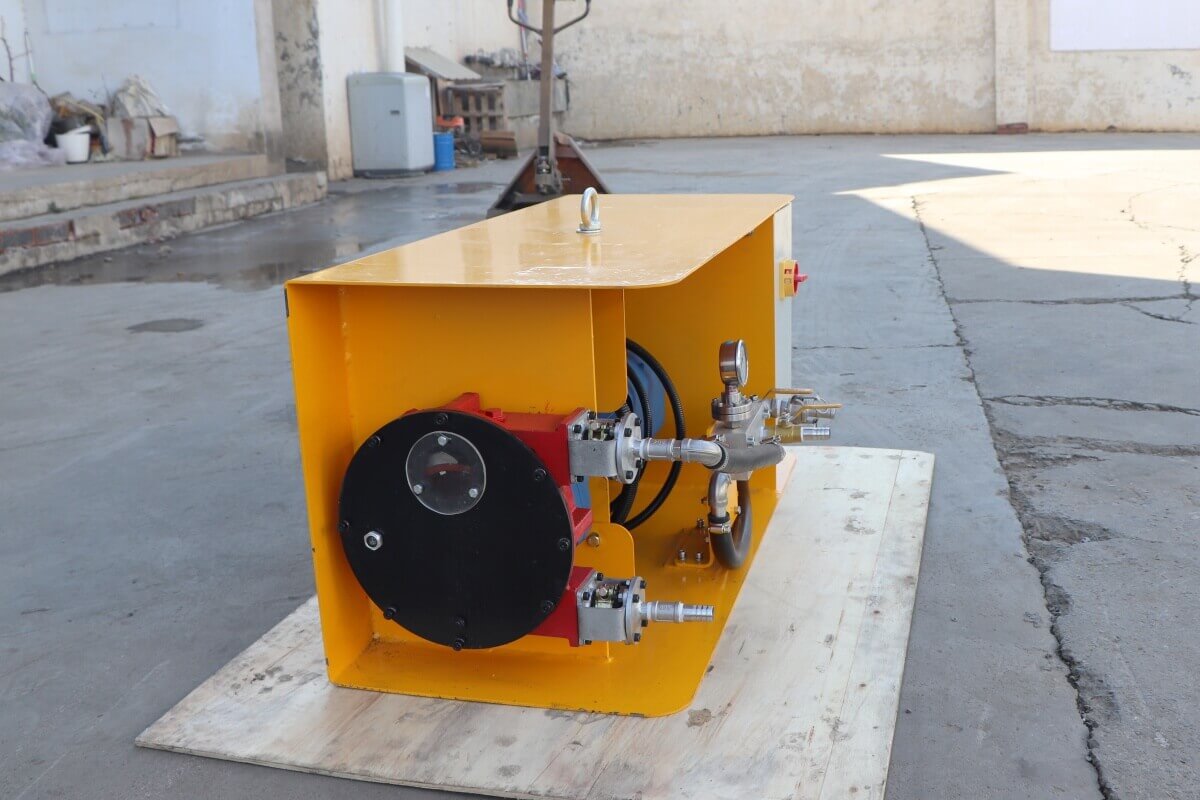

The air liquid dosing system for shotcrete liquid admixtures into shotcrete is a specially designed system. It is designed to add additives for both dry and wet spraying processes. Driven by compressed air, this system boasts a more compact, safe, and reliable structure. Such a system is crucial for ensuring the quality and performance of shotcrete, particularly in applications such as underground construction, tunnel engineering, and the repair and reinforcement of existing structures.

Main functions and features of air liquid dosing system for shotcrete liquid admixtures:

Precise Metering: It can accurately add liquid admixtures to the concrete mixture according to preset ratios, ensuring consistency and reliability of the mixture.

Automated Operation: Many modern systems support automatic operation, allowing pre-set addition ratios and time intervals, which reduces manual intervention and enhances work efficiency.

High Adaptability: It can adjust the addition amount based on different construction needs and environmental conditions, ensuring optimal construction results.

Integrated Control System: Typically equipped with an integrated control system, it can monitor the system's operational status in real-time and make adjustments as needed.

The main advantages of using an air liquid dosing system include improved work efficiency, guaranteed construction quality, reduced material waste, and enhanced safety in the working environment.

Main application areas of air liquid dosing system for shotcrete liquid admixtures:

Underground construction projects

In underground tunnels, basements, subways and other projects, shotcrete is often used for support and lining. The air liquid dosing system can accurately add admixtures to improve the strength and durability of concrete to meet the special requirements of underground projects.

Tunnel and slope projects

Tunneling and slope support require fast-hardening concrete to provide immediate support. By adding admixtures such as accelerators, the air liquid dosing system can accelerate the setting process of concrete to ensure construction safety and progress.

Repair and reinforcement projects

For the repair and reinforcement of existing structures, such as bridges and building exterior walls, high-quality concrete is required to ensure the stability and safety of the structure. The air liquid dosing system can accurately control the amount of admixtures added to improve the bonding and durability of concrete.

Hydraulic projects

In hydraulic projects such as dams and embankments, shotcrete is often used for anti-seepage and reinforcement. By adding admixtures such as anti-seepage agents and water reducers, the air liquid dosing system can improve the impermeability and fluidity of concrete and improve construction efficiency and quality.

Other special projects

For projects that require rapid construction and high-strength concrete, such as mine support and military bunkers, the air liquid dosing system also has broad application prospects.

Specific application advantages of air liquid dosing system for shotcrete liquid admixtures:

Precise dosing and control

The air-liquid dosing system can accurately add admixtures to concrete according to the preset proportion to ensure the stability and consistency of concrete performance.

Automation and intelligence

Modern air liquid dosing systems are usually equipped with automated control systems that can pre-set the addition ratio and time interval, reduce manual intervention, and improve work efficiency. At the same time, the integrated control system can also monitor the operating status of the system in real time and adjust it as needed.

Strong adaptability

The air liquid dosing system can adjust the amount of admixture added according to different construction requirements and environmental conditions to ensure the best construction effect. For example, in cold or hot climates, the construction performance and durability of concrete can be improved by adjusting the type and amount of admixtures.

Energy saving and environmental protection

By accurately controlling the amount of admixtures added, the air-liquid dosing system can reduce material waste and energy consumption. At the same time, adding appropriate admixtures can also improve the strength and durability of concrete, extend the service life of the project, and thus reduce maintenance and repair costs.

The air-liquid dosing system has a wide range of applications and significant application advantages in shotcrete liquid admixtures. It can accurately control the amount of admixture added, improve the construction performance and durability of concrete, and meet the needs of various complex projects. Email address: sales1@leadcrete.com

(English)

-

English

English -

Arabic

Arabic -

Bulgarian

Bulgarian -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

Finnish

Finnish -

French

French -

German

German -

Greek

Greek -

Hindi

Hindi -

Italian

Italian -

Japanese

Japanese -

Korean

Korean -

Norwegian

Norwegian -

Polish

Polish -

Portuguese

Portuguese -

Romanian

Romanian -

Russian

Russian -

Spanish

Spanish -

Swedish

Swedish -

Catalan

Catalan -

Filipino

Filipino -

Hebrew

Hebrew -

Indonesian

Indonesian -

Latvian

Latvian -

Lithuanian

Lithuanian -

Serbian

Serbian -

Slovak

Slovak -

Slovenian

Slovenian -

Ukrainian

Ukrainian -

Vietnamese

Vietnamese -

Albanian

Albanian -

Estonian

Estonian -

Galician

Galician -

Hungarian

Hungarian -

Maltese

Maltese -

Thai

Thai -

Turkish

Turkish -

Persian

Persian -

Afrikaans

Afrikaans -

Malay

Malay -

Swahili

Swahili -

Irish

Irish -

Welsh

Welsh -

Belarusian

Belarusian -

Icelandic

Icelandic -

Macedonian

Macedonian -

Yiddish

Yiddish -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Georgian

Georgian -

Haitian Creole

Haitian Creole -

Urdu

Urdu -

Bengali

Bengali -

Bosnian

Bosnian -

Cebuano

Cebuano -

Esperanto

Esperanto -

Gujarati

Gujarati -

Hausa

Hausa -

Hmong

Hmong -

Igbo

Igbo -

Javanese

Javanese -

Kannada

Kannada -

Khmer

Khmer -

Lao

Lao -

Latin

Latin -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Nepali

Nepali -

Punjabi

Punjabi -

Somali

Somali -

Tamil

Tamil -

Telugu

Telugu -

Yoruba

Yoruba -

Zulu

Zulu -

Myanmar (Burmese)

Myanmar (Burmese) -

Chichewa

Chichewa -

Kazakh

Kazakh -

Malagasy

Malagasy -

Malayalam

Malayalam -

Sinhala

Sinhala -

Sesotho

Sesotho -

Sudanese

Sudanese -

Tajik

Tajik -

Uzbek

Uzbek -

Amharic

Amharic -

Corsican

Corsican -

Hawaiian

Hawaiian -

Kurdish (Kurmanji)

Kurdish (Kurmanji) -

Kyrgyz

Kyrgyz -

Luxembourgish

Luxembourgish -

Pashto

Pashto -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Shona

Shona -

Sindhi

Sindhi -

Frisian

Frisian -

Xhosa

Xhosa

More Language

Your position:

Home > News > Product News

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.

.jpg)

.jpg)