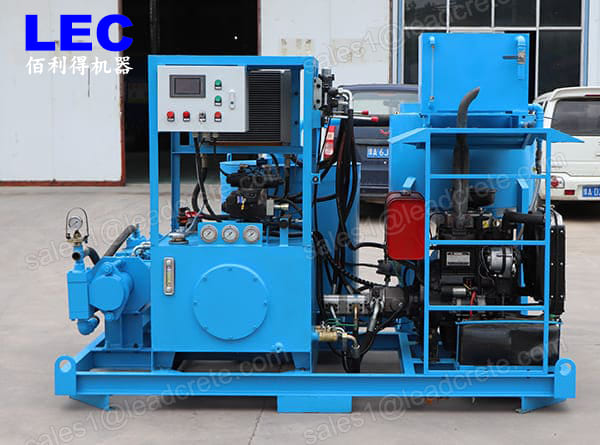

Tunnel Lining Cement Slurry Bentonite Mixing Plant

The tunnel lining cement slurry bentonite mixing station integrates multiple functions such as raw material storage, metering, mixing and transportation, and is specially designed for lining operations in tunnel projects. It can mix raw materials such as cement, bentonite, and water in a certain proportion to prepare cement slurry bentonite mixtures that meet the requirements of tunnel lining.

Tunnel lining cement slurry bentonite mixing plants are widely used in various tunnel projects, such as highway tunnels, railway tunnels, and water conservancy tunnels. It can provide high-quality cement slurry bentonite mixtures for tunnel linings to ensure the stability and safety of tunnel projects.

Tunnel lining cement slurry bentonite mixing plant main components:

Raw material storage system: including cement silos, bentonite silos, etc., used to store raw materials such as cement and bentonite.

Metering system: through electronic scales and other metering equipment, the proportions of various raw materials are accurately weighed to ensure the accuracy of the mixture.

Mixing system: usually a twin-shaft forced mixer or other high-efficiency mixer is used to fully mix various raw materials.

Conveying system: including screw conveyor, belt conveyor, etc., used to transport the mixed cement slurry bentonite mixture to the tunnel lining construction site.

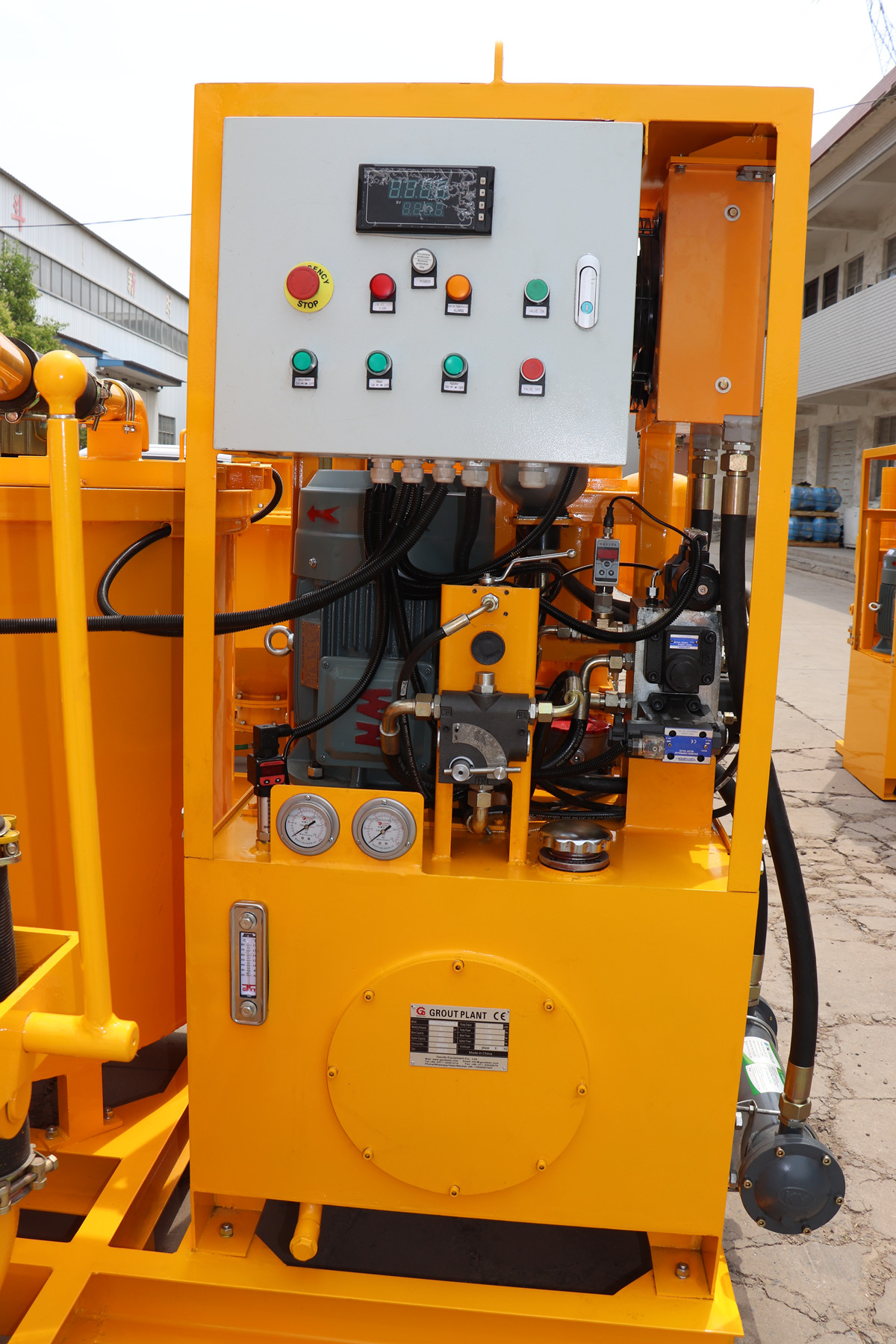

Control system: PLC or other advanced control systems are used to realize automatic control and remote monitoring of equipment.

Working principle of tunnel lining cement slurry bentonite mixing plant:

The working principle of the tunnel lining cement slurry bentonite mixing station is as follows:

Raw material preparation: Cement, bentonite and other raw materials are added to their respective storage bins in a certain proportion.

Metering and batching: The proportions of various raw materials are accurately weighed through the metering system and sent to the mixing system.

Mixing: In the mixing system, various raw materials are forced to mix to form a uniform cement slurry bentonite mixture.

Conveying and application: The mixed cement slurry bentonite mixture is transported to the tunnel lining construction site through the conveying system for lining operations.

Tunnel lining cement slurry bentonite mixing plant characteristics and advantages:

High degree of automation: Advanced control systems are used to realize automatic control and remote monitoring of equipment, reducing manual operation costs.

Accurate measurement: Through a precise metering system, the proportions of various raw materials are ensured to be accurate and the quality of the mixture is guaranteed.

High mixing efficiency: using high-efficiency mixer, high mixing efficiency, uniform mixing, meeting the requirements of tunnel lining for mixed materials.

Wide range of applications: can be used for tunnel projects of different scales and types to meet the needs of different lining operations.

If you have any need about our tunnel lining cement slurry bentonite mixing plant, please contact us by email sales1@leadcrete.com