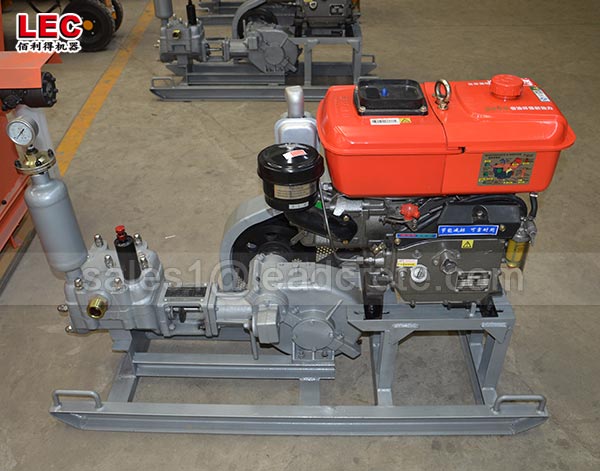

Supply high pressure grouting pump machine

After the remaining material in the supply high pressure grouting pump machine tube is used up, immediately wash it with clean water. The cleaned water should be cleaned with clean water as the cleaning standard. Then the machine tube and the material tube are stored indoors for the next use.

Supply high pressure grouting pump machine maintenance:

1. Before using the cement grouting machine, add a proper amount of grease to the movable hinge of the rocker arm, and shake the handle at a uniform speed to ensure flexible use and prevent corrosion.

2. When the fasteners are found to be loose during use, they should be tightened in time.

3. Shake the handle with moderate force to prevent damage to the parts.

4. All joints of the inlet and outlet pipes are tightly connected with the supply high pressure grouting pump machine body after being fastened with steel wire clamps. If poor inhalation performance is found, the following measures should be taken:

(1) Check the tightness of the joints at the feed end.

(2) Check whether the feed pipe is damaged or leaking.

(3) Check whether there are materials in the charging barrel.

(4) Check whether the discharge port is loose or blocked by debris. Take the following measures when poor discharge occurs:

① Check if the drain pipe is blocked. ② Check if the drain valve is open.

5. When grouting, the discharge pipe must be placed steadily, otherwise it will directly affect the construction operation.

6. Note that the mud should not contain sand, so as not to affect the service life of the machine.

6. When using outdoors in winter, pay attention to the following matters when the temperature is below zero:

(1) The use time should not be too long.

(2) The prepared grout is filled at once.