Shotcrete machines with accelerator system

Shotcrete machines equipped with accelerator systems are specialized equipment used for spraying concrete (shotcrete) onto surfaces with the addition of chemical accelerators.

Shotcrete machines with accelerator system:

Purpose: Enhances the shotcrete process by adding accelerators to the concrete mix, which speed up setting times and improve early strength development.

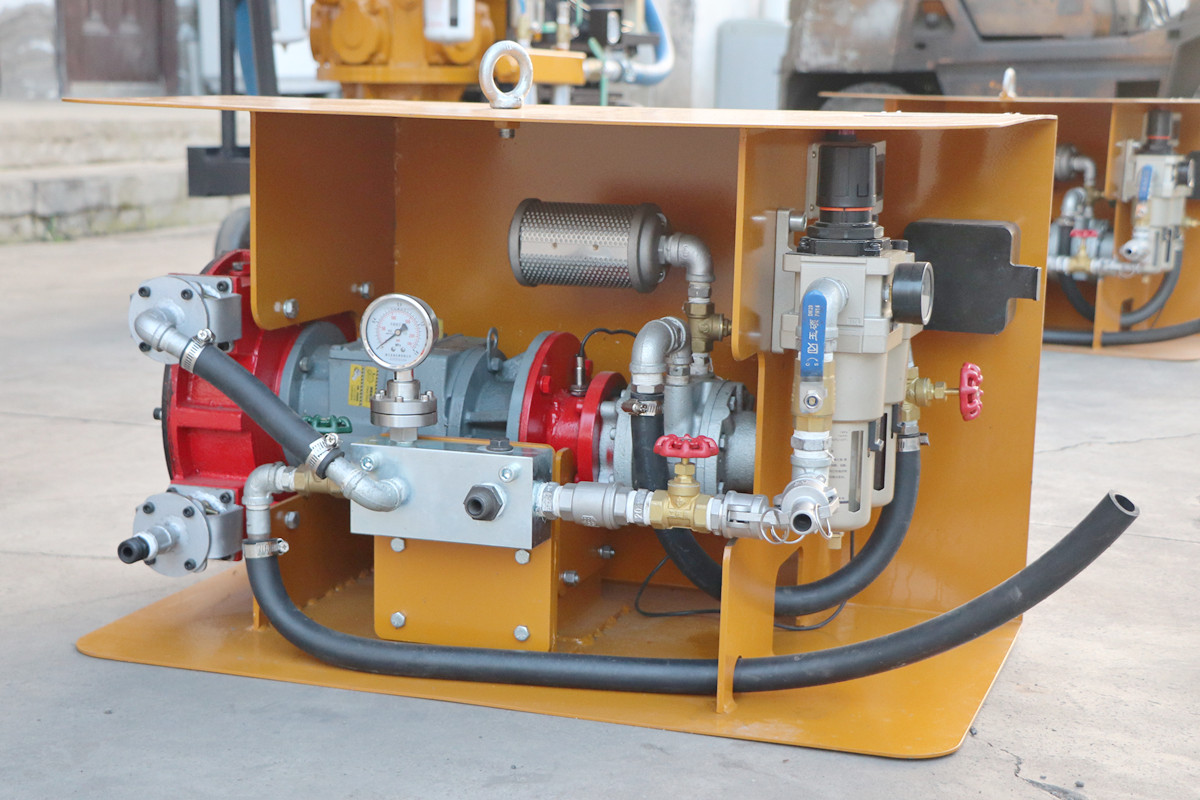

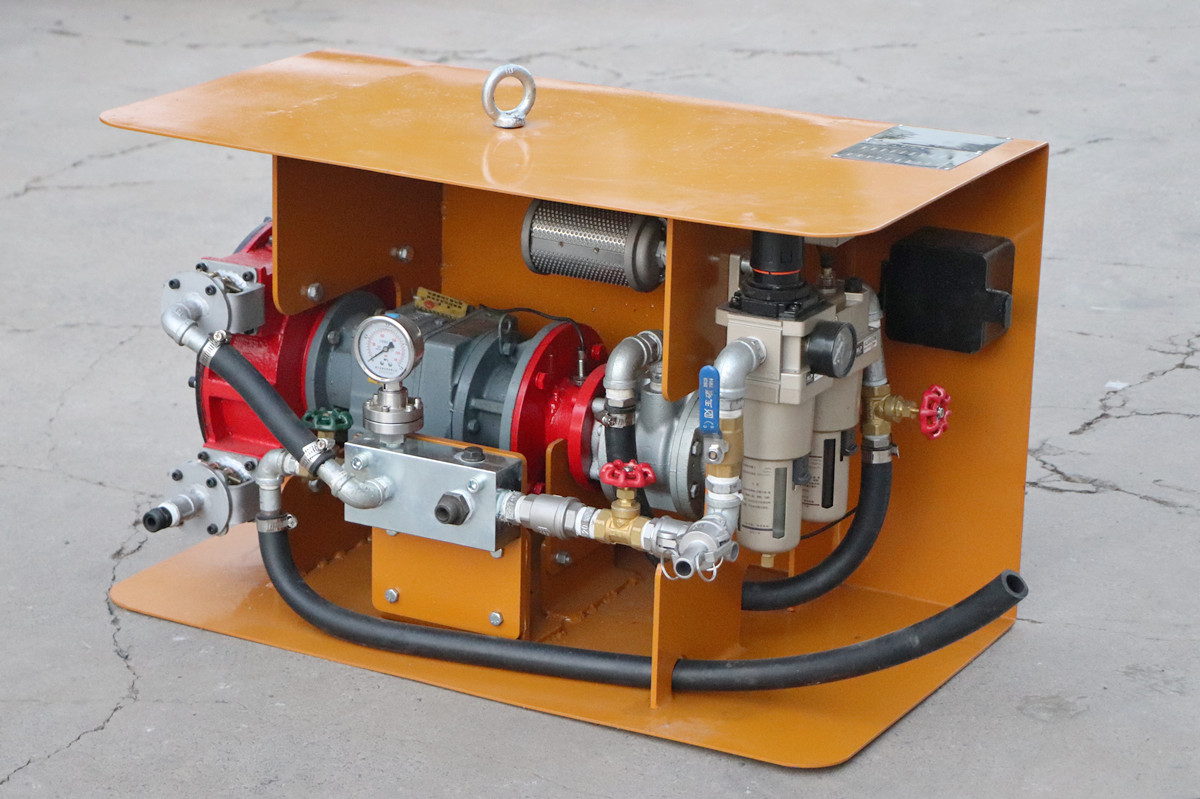

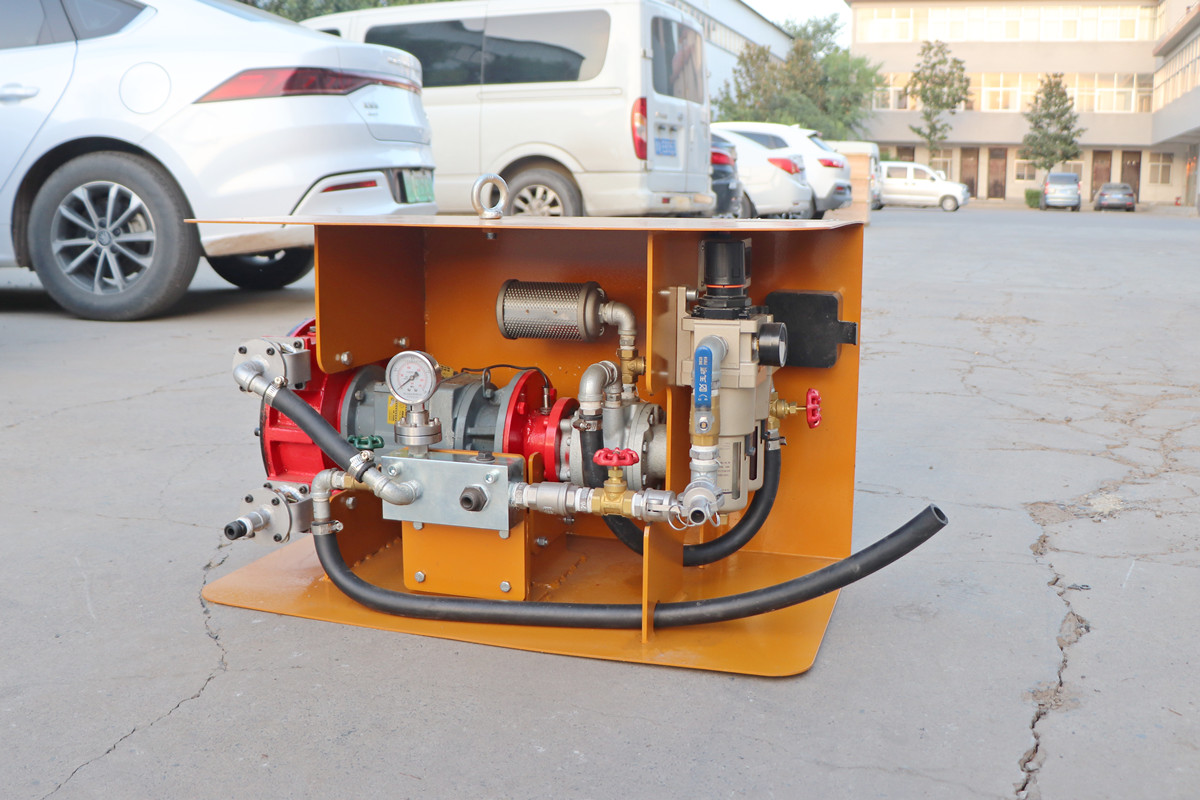

Components:

Dosing Pump: Precisely meters the accelerator additives into the concrete mix from storage tanks or containers.

Storage Tanks: Hold the accelerator solutions, ensuring continuous supply during operation.

Injection System: Comprises pipelines, valves, and fittings that transport the accelerator solution from the storage tanks to the dosing pump and then to the mixing chamber or nozzle of the shotcrete machine.

Control System: Includes electronic controls for monitoring and adjusting dosing parameters, ensuring precise dosing rates according to project requirements.

Advantages of shotcrete machines with accelerator system:

– **Time Efficiency**: Accelerators shorten concrete curing times, facilitating rapid construction and repair activities.

– **Improved Strength**: Enhances early-age strength development, allowing for quick structural integrity and further construction stages.

– **Versatility**: Suitable for various shotcrete applications, including underground support, slope stabilization, and structural repairs.