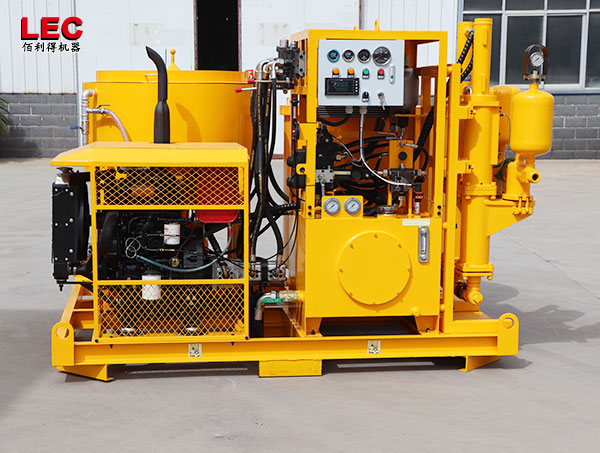

Pressure injection grouting equipment

Pressure injection grouting equipment consists of proven factory standard components agitator, agitator and grout pump. This setup is suitable for a wide range of applications such as anchoring, casing, contact, and backfill grouting. To increase throughput and enhance quality control, these plants are also available in semi-automatic and fully-automatic versions.

Pressure injection grouting equipment is a combination of a mixer, agitator, and grouting pump in one device. The special mixing effect of cement or bentonite with water is achieved in the mixer by the high turbulence generated in the pump casing. This turbulent flow with high shear forces separates the cement or bentonite particles to form a fully hydrated suspension.

Pressure injection grouting equipment is mainly used for mortar grouting in municipal, highway, railway, hydropower, construction, mine, and other construction sites. The pressure injection grouting equipment is driven by an electric motor and a mechanical plunger injection pump. Small size, easy operation, small footprint. The grouting pump adopts frequency conversion speed regulation, and the flow rate is steplessly adjustable.

Once the mixing process is complete, transfer the mixture to a blender. A slow stirring paddle prevents the grout from settling out of suspension and removes any air bubbles in the mixture. Each machine is equipped with mixers and pumps of matching capacity, plus an agitation storage tank, allowing for near-continuous operation once work begins.