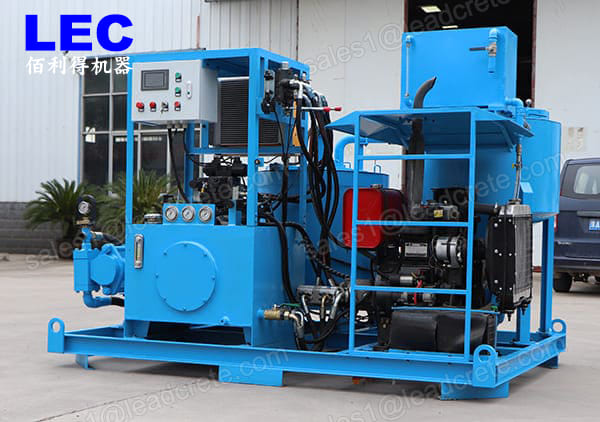

Permeation grouting equipment

In response to hydraulic, mining, geological disasters, and other emergency grouting projects. Our company has studied the coal mine emergency grouting station with integrated permeation grouting equipment as the core. The system is efficient, safe, and reliable. Applicable materials: cement, fly ash, mineral powder, loess, etc. Single or mixed slurries can be prepared.

Permeation grouting equipment is a combination of a grout mixer, agitator, and grout pump in one plant.

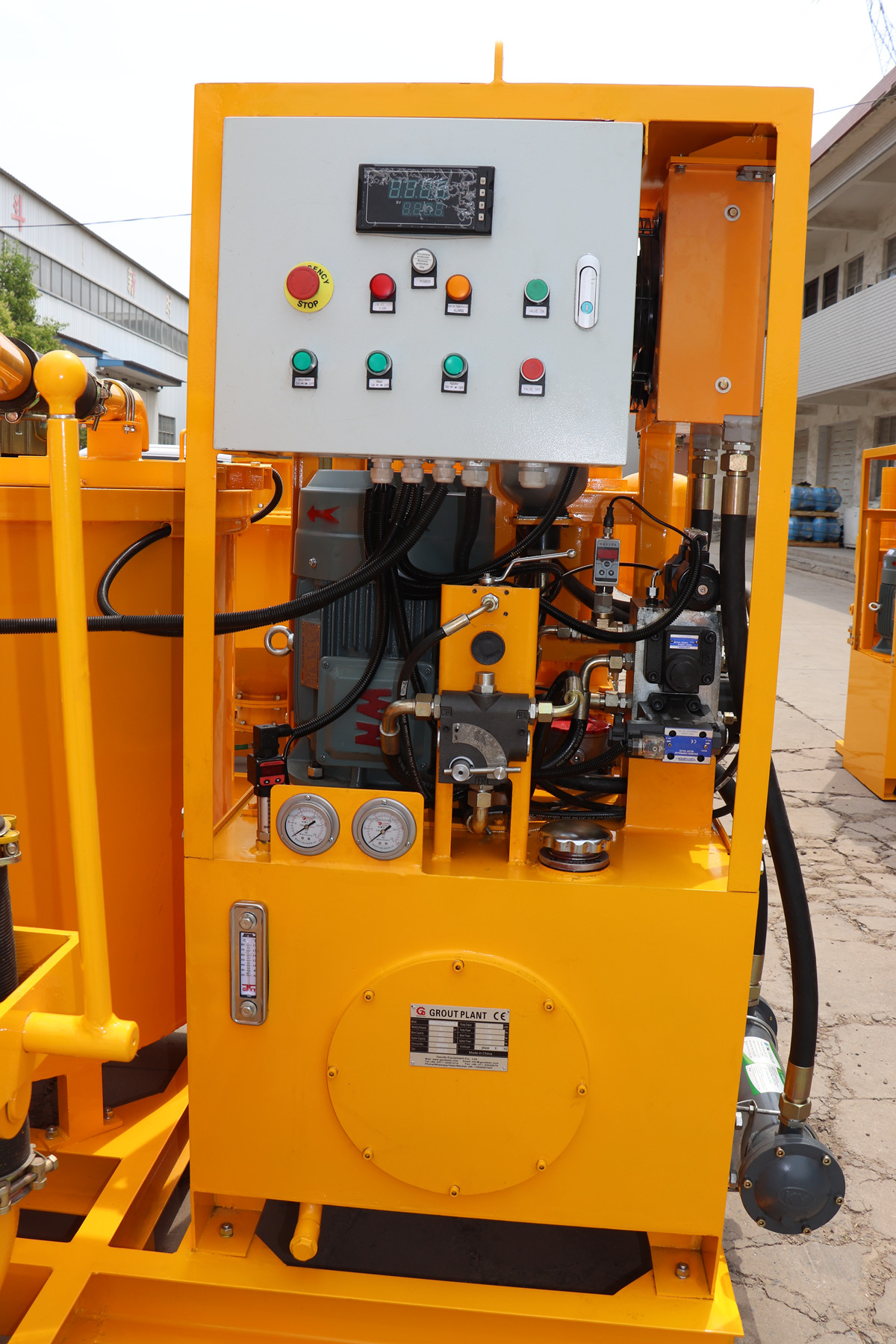

How permeation grouting equipment works:

The high-speed vortex mixer of Permeation grouting equipment ensures fast and uniform mixing. Quickly mix water, cement, or bentonite into a homogeneous slurry. The mixed slurry is then sent to a mixer. The grouting pump injects from the mixing drum (storage tank). This ensures continuous mixing and grouting operations. Permeation grouting equipment is fully hydraulically driven by a diesel engine or electric engine. The grouting pressure and displacement are steplessly adjustable. Small size, easy to operate. It also takes up very little space.

Permeation grouting equipment is mainly used in highways, railways, hydropower, construction, mining, and other ground and underground construction.