Liquid accelerator dosing system for shotcrete

A liquid accelerator dosing system for shotcrete is a specialized system designed to meter and inject liquid accelerators into a shotcrete mixture. These accelerators are chemicals that can significantly reduce the setting time of shotcrete, allowing for faster construction and reinforcement processes.

Components and functionality of liquid accelerator dosing system for shotcrete:

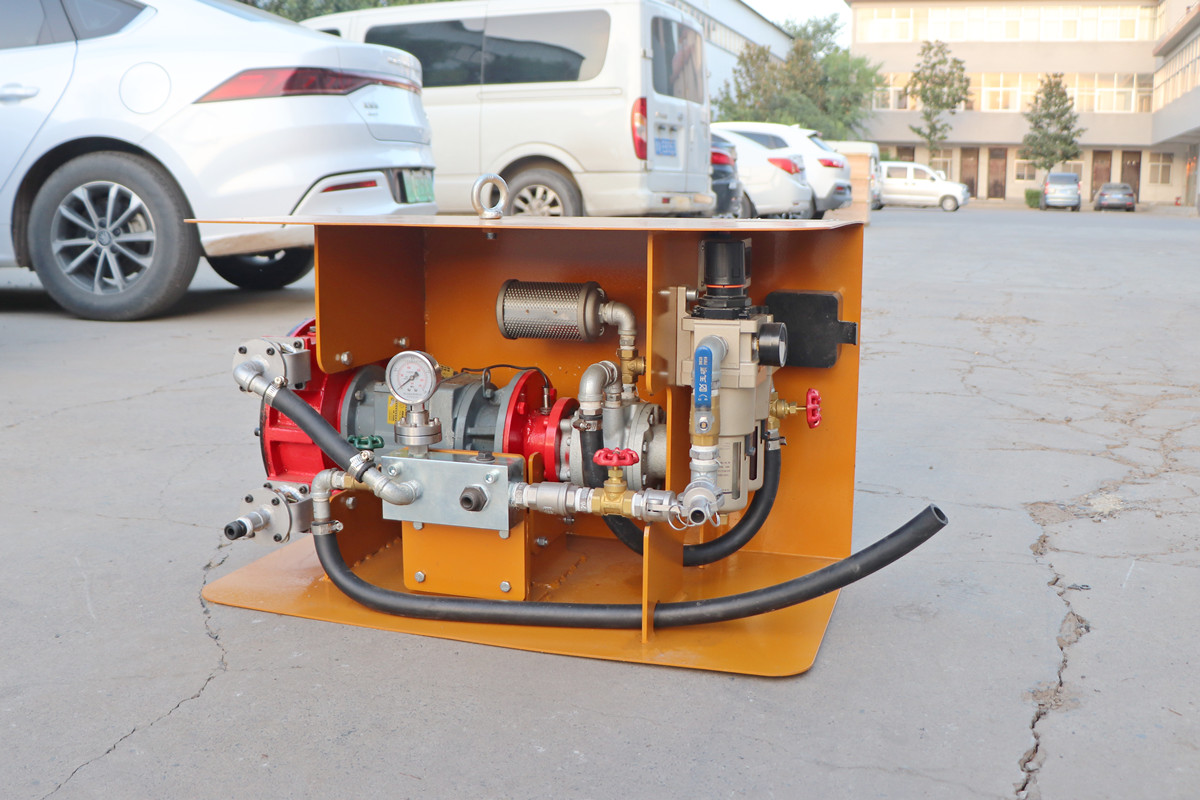

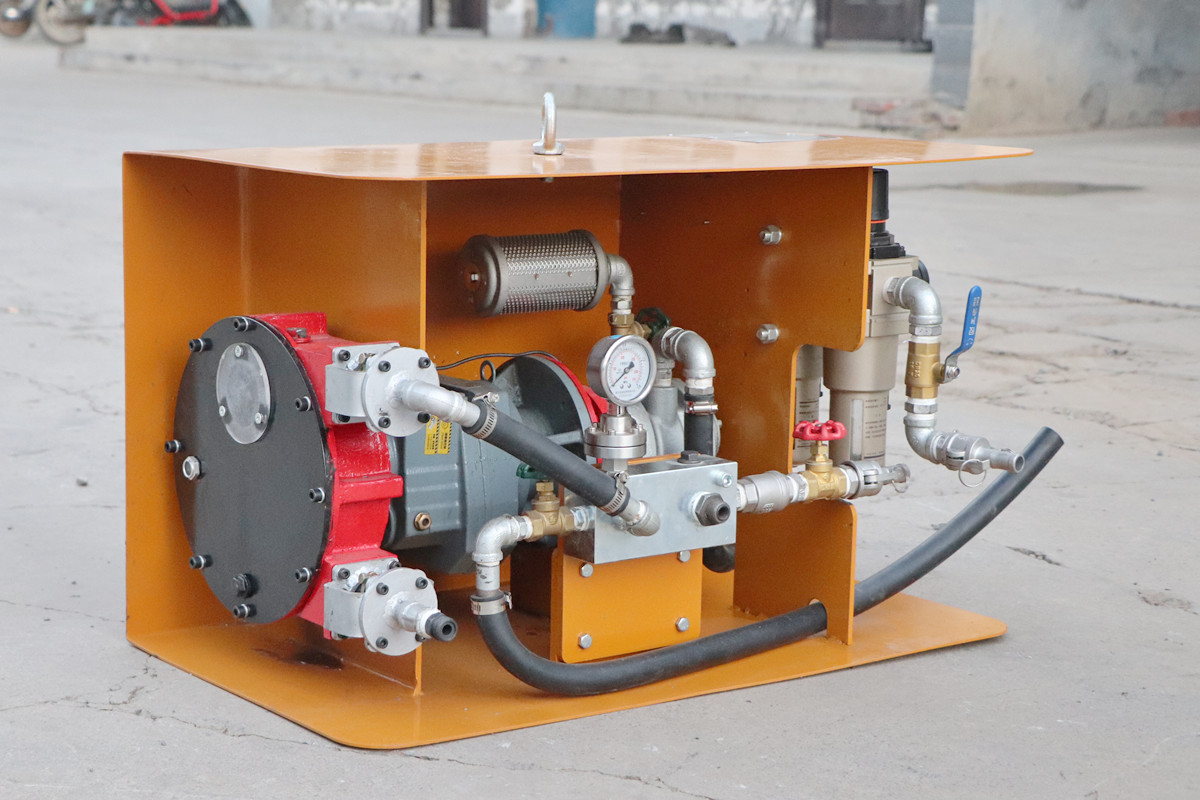

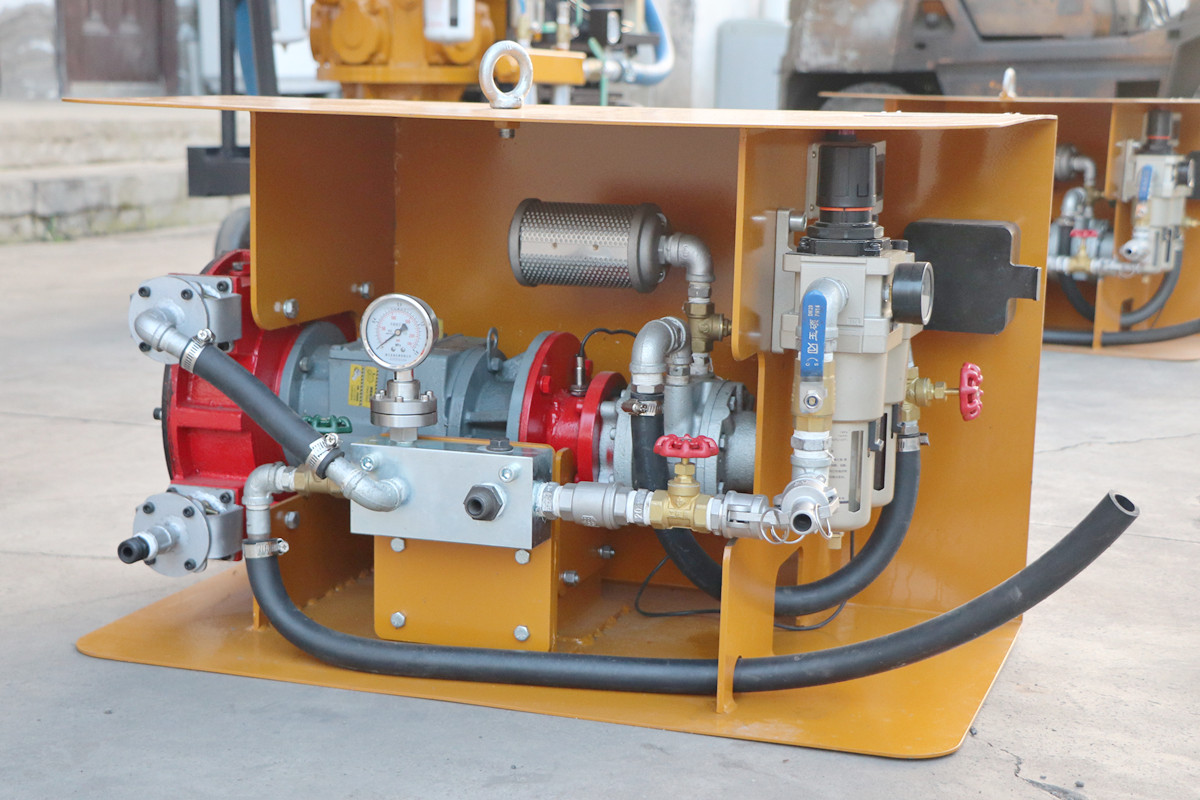

1. **Dosing Pump Unit**:

– **Purpose**: The core component responsible for accurately metering and injecting liquid accelerators into the concrete mixture.

– **Precision Dosing**: Utilizes a dosing pump that ensures consistent and controlled delivery of the accelerator solution from storage tanks or containers.

– **Adjustability**: Allows operators to adjust dosing parameters such as flow rate, concentration, and timing to meet specific project requirements for strength development and setting times.

2. **Storage and Handling**:

– **Accelerator Storage**: Liquid accelerators are stored in dedicated tanks or containers that are integrated into the dosing system.

– **Transfer and Injection**: Includes pipelines, valves, and fittings that transport the accelerator solution from the storage tanks to the dosing pump unit and eventually to the mixing chamber or nozzle of the shotcrete machine.

– **Compatibility**: The system is designed to handle a variety of liquid accelerator types and concentrations, ensuring versatility in different shotcrete applications.

3. **Integration with Shotcrete Equipment**:

– **Seamless Integration**: Integrated into the shotcrete machine’s overall operation, working in conjunction with concrete mixers, pumping systems, and spraying nozzles.

– **Control System**: Incorporates electronic controls and sensors that provide real-time monitoring and adjustment of dosing parameters. This enables operators to maintain precise accelerator dosing throughout the spraying process, optimizing performance and quality.

4. **Advantages**:

– **Enhanced Efficiency**: Liquid accelerators significantly reduce concrete setting times, enabling faster construction schedules and project completion.

– **Consistent Quality**: Ensures uniform concrete properties and performance by maintaining precise and reliable dosing of accelerators.

– **Flexibility**: Allows for adjustments in dosing rates and accelerator concentrations to accommodate varying project requirements and environmental conditions.

5. **Maintenance and Safety**:

– **Regular Maintenance**: Routine upkeep of the dosing system ensures optimal performance and extends equipment lifespan.

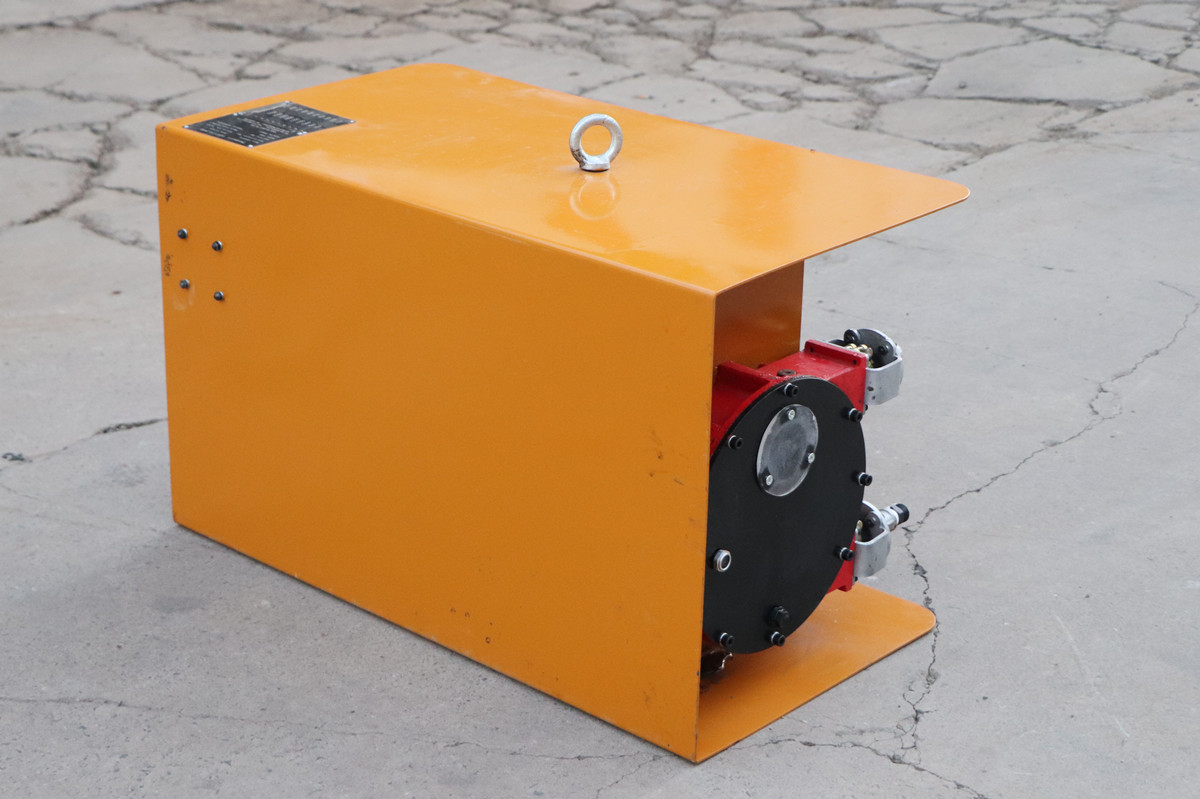

– **Safety Features**: Incorporates safety measures such as emergency shut-off valves, leak detection systems, and protective enclosures to enhance operational safety during shotcrete spraying.

6. **Application Specificity**:

– **Versatility**: Suitable for a wide range of shotcrete applications, including tunneling, mining, slope stabilization, and structural repairs.

– **Environmental Adaptability**: Capable of operating in diverse environmental conditions and adapting to different shotcrete mixes and project specifications.

In summary, a liquid accelerator dosing system for shotcrete is essential for achieving efficient and high-quality concrete spraying applications. It combines advanced dosing technology with robust shotcrete equipment to deliver precise control over concrete setting times, ensuring optimal performance and durability in construction projects.