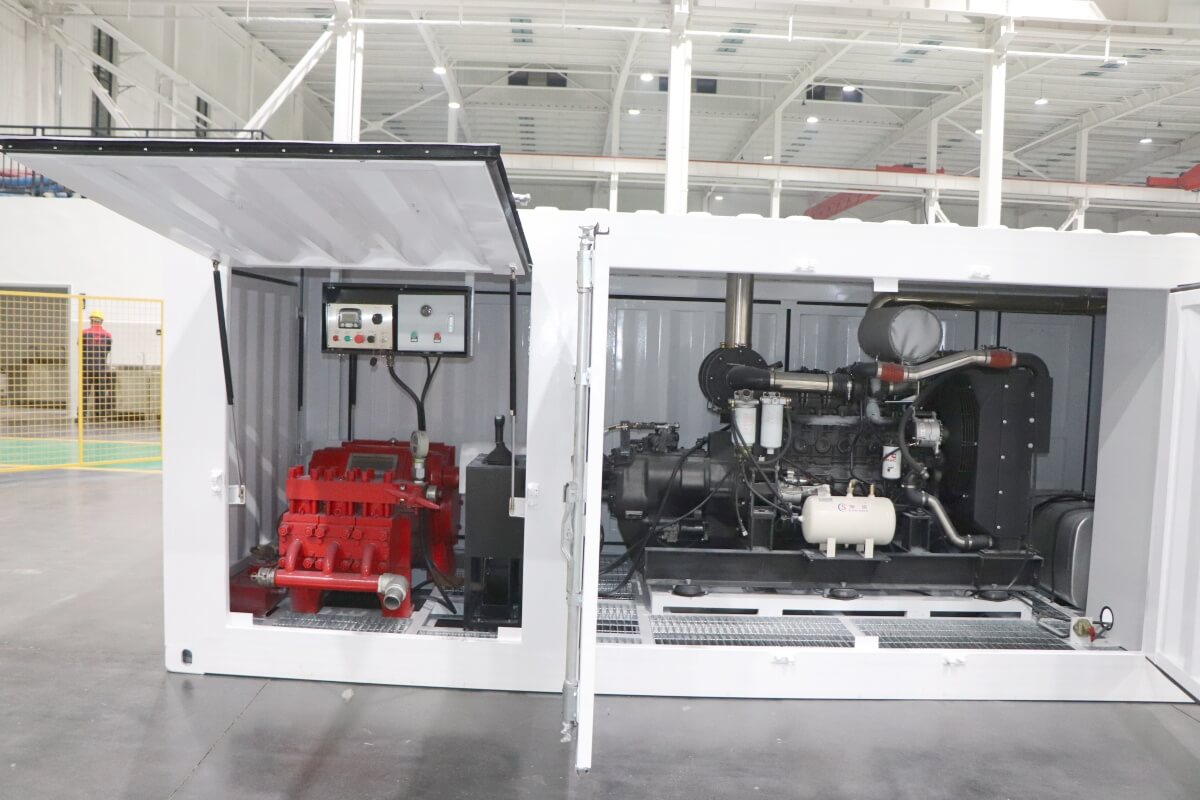

jet grout pump in container

Regarding the jet grout pump in container, it is a high-pressure grouting pump capable of generating up to 100 bar pressure, mainly used in engineering projects that require high-pressure grouting.

The jet grout pump in container is an efficient and high-pressure grouting equipment that injects grout into the interior of rock and soil under high pressure, forming a reinforcement or water stop layer. This device is widely used in the fields of grouting reinforcement, waterproofing and seepage prevention in subway, tunnel, bridge, foundation pit and other engineering projects.

Technical features of jet grout pump in container:

High pressure grouting: This pump can generate a pressure of up to 100 bar, ensuring that the slurry can penetrate deep into the rock and soil, forming an effective reinforcement or water stop layer.

Adjustable flow rate: According to engineering requirements, the flow rate of the pump can be adjusted to meet different grouting requirements.

Good stability: Advanced pumping technology and control system are adopted to ensure the stability and reliability of the grouting process.

Strong adaptability: Suitable for various geological conditions, including different types of rock and soil such as sand, clay, and rock.

Application area of jet grout pump in container:

The 100bar jet grout pump is widely used in engineering projects that require high-pressure grouting, such as:

Grouting reinforcement and waterproofing for underground engineering such as subways and tunnels.

Grouting reinforcement of bridge pile foundations to improve their bearing capacity.

Construction of waterproof curtain for foundation pit engineering to prevent groundwater seepage.

Grouting reinforcement for slope stability engineering to improve slope stability.