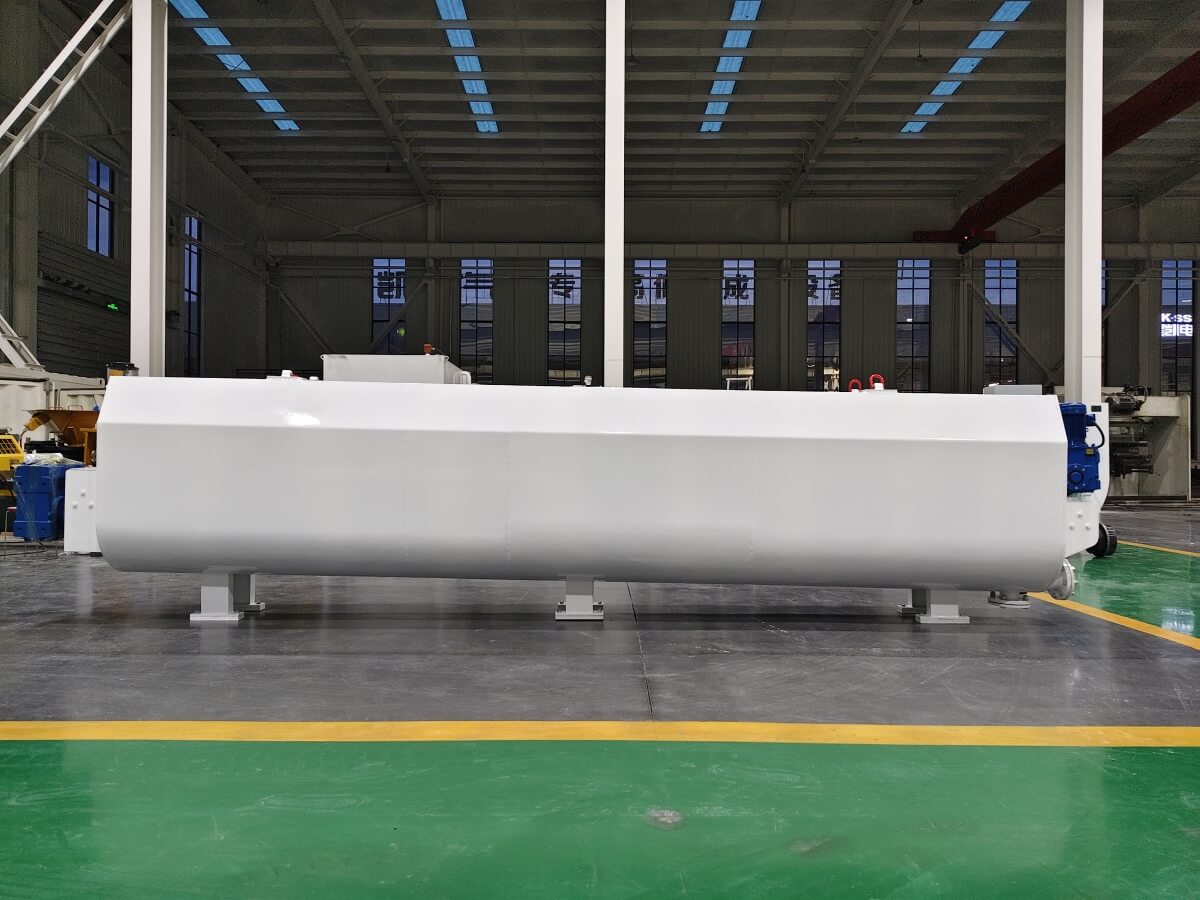

High Volume Hose Pumps in Shale Gas Project

High Volume Hose Pumps are essential equipment in shale gas projects, especially during hydraulic fracturing operations. These pumps are used to inject large amounts of fracturing fluid (usually containing water, sand, and chemical additives) at high pressure into underground rock formations to release natural gas.

High Volume Hose Pumps play an important role in shale gas projects.

1. Characteristics of High Volume Hose Pumps

Abrasion resistance: Hose pumps are suitable for abrasive media. Since the hose has no restrictions on the wear of the media, there is no seal, and no other parts are in contact with the media, it is particularly suitable for handling abrasive fluids that may be encountered during shale gas extraction.

High viscosity adaptability: Hose pumps can produce almost full vacuum to suck in the medium, which is suitable for high viscosity media. Some fluids used in shale gas extraction may have high viscosity, and this feature of hose pumps enables them to easily cope with it.

No backflow design: The squeeze-off positive action of the hose pump between the rotor and the pump body prevents backflow, so there is no need to install a check valve to prevent fluid backflow when the pump stops running. This feature helps maintain the stability of fluid flow and reduce energy loss.

Easy maintenance: Hose pumps are simple to install, easy to operate, and have low maintenance costs. The hose is the only wear part, and the repair time is extremely short, reducing downtime and maintenance costs.

2. Application of high-flow hose pumps in shale gas projects

Drilling operations: During shale gas drilling, high-flow hose pumps can be used to transport drilling mud, flushing fluids, etc. These fluids are usually abrasive and highly viscous, and the characteristics of hose pumps enable them to transport these fluids efficiently and stably.

Fracturing operations: Fracturing is a key step in shale gas extraction, and a large amount of fracturing fluid needs to be injected into the wellbore. High-flow hose pumps can complete this task quickly and accurately to ensure the success of fracturing operations.

Fluid recovery and treatment: During shale gas extraction, a large amount of wastewater, waste liquid, etc. will be generated. High-flow hose pumps can be used to recover and treat these fluids to ensure environmental safety and production efficiency.

3. Advantages of high-flow hose pumps

Improve production efficiency: High-flow hose pumps can quickly and accurately transport large amounts of fluids, improving the production efficiency of shale gas extraction.

Reduced maintenance costs: Hose pumps are easy to maintain, with short repair time, reducing downtime and maintenance costs.

Enhanced safety: The hose pump has no sealing leakage points, eliminating the danger of the hose pump body contaminating the fluid or the fluid contaminating the pump body, and improving the safety of the operation.

In summary, high-flow hose pumps have broad application prospects and significant advantages in shale gas projects. By properly selecting and maintaining hose pumps, the smooth progress of the shale gas extraction process can be ensured, production efficiency can be improved, maintenance costs can be reduced, and the safety of operations can be enhanced.