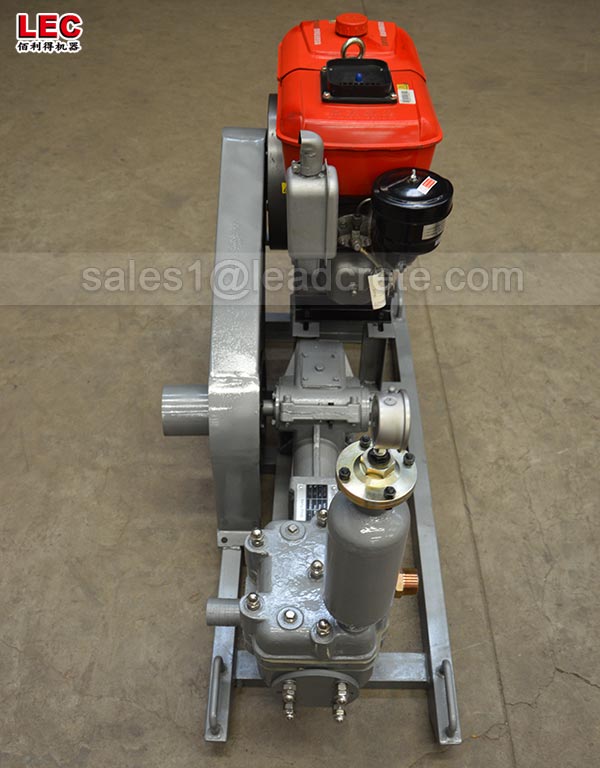

High pressure plunger grout pump

A high-pressure plunger grout pump is a specialized piece of equipment designed for injecting grout materials into substrates at elevated pressures, typically used in demanding construction and repair applications. These pumps are chosen for their ability to handle thick, viscous grouts and inject them into tight spaces or deep layers of soil or concrete with precision and control.

High Pressure Plunger Grout Pump is a device used to transport high-pressure cement grouting materials. High Pressure Plunger Grout Pump is an efficient, stable, and reliable high-pressure grouting equipment with broad application prospects in geological engineering, civil engineering, and hydraulic engineering fields.

Applications of high pressure plunger grout pump:

- Deep Foundation Grouting: Used for soil compaction, pile grouting, and foundation stabilization to increase load-bearing capacity.

- Concrete Crack Repair: Ideal for injecting epoxy or cementitious grouts into cracks in concrete structures to restore strength and prevent further damage.

- Tunnel and Mine Support: Injecting grout to stabilize rock formations, seal leaks, and reinforce tunnel linings.

- Geotechnical Engineering: For soil improvement, landslide prevention, and dam repair, where high-pressure injection stabilizes and strengthens the ground.

- Post-Tensioning Grouting: Ensures complete encapsulation of post-tensioning tendons to protect against corrosion and enhance structural integrity.

- Waterproofing and Sealing: Injecting waterproofing compounds into joints, cracks, and below-grade structures to prevent water infiltration.

When selecting a high-pressure plunger grout pump, consider the specific demands of your project, including the required pressure and flow rates, grout type, and the environment in which the pump will operate. It’s advisable to consult with manufacturers or experienced suppliers who can guide you towards the most suitable model for your application.