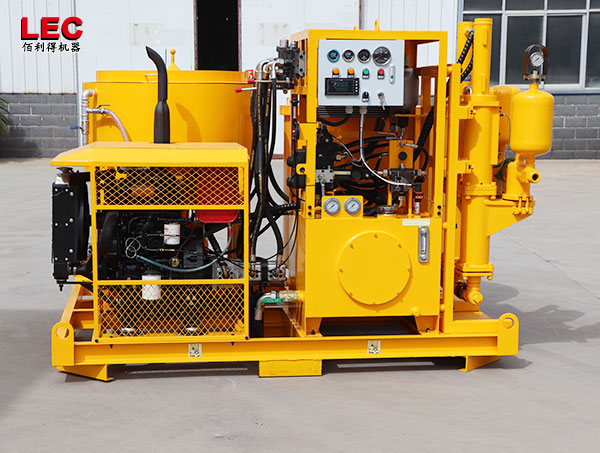

High pressure cement grout plant

High pressure cement grouting equipment is widely used in the following fields:

Geological engineering: used for foundation reinforcement, slope stability, tunnel support and other operations.

Civil engineering: used for grouting reinforcement and crack filling in bridges, tunnels, subways and other engineering projects.

Hydraulic engineering: used for foundation treatment and anti-seepage reinforcement of hydropower stations, reservoirs, embankments and other projects.

High pressure cement grout plant is a comprehensive equipment that integrates functions such as raw material storage, automatic metering, mixing and stirring, and high-pressure conveying. It is mainly used for grouting reinforcement, crack filling, foundation treatment and other operations in geological engineering, civil engineering, water conservancy engineering and other fields.

Main features of high pressure cement grout plant:

High pressure output: This device uses a plunger pump or other high-pressure pump as the power source, capable of outputting pressures up to hundreds of bars, ensuring that the cement slurry can fully penetrate the target area.

Automatic metering and mixing: The equipment is equipped with an automatic metering and mixing system, which can accurately control the proportion of raw materials such as cement, water, and additives to ensure the quality of grouting materials.

Efficient production: The equipment adopts advanced mixing technology and control system, which can achieve fast and continuous preparation and transportation, and improve construction efficiency.

Environmental protection and energy conservation: The equipment fully considers environmental and energy-saving requirements in the design and manufacturing process, adopts low noise, low energy consumption driving systems and sealing structures, and reduces the impact on the environment.

Technical specifications of high pressure cement grout plant:

Mixing capacity: According to different models and specifications, the mixing capacity of the equipment is usually between tens to hundreds of cubic meters.

Production capacity: The production capacity of equipment depends on factors such as mixing capacity, mixing speed, and conveying capacity, and can generally reach a production volume of tens of cubic meters per hour.

Output pressure: The output pressure of a device is one of its key performance indicators, usually reaching hundreds of bars or even higher.

Other parameters include water cement ratio, circulation capacity, transportation distance, etc., all of which directly affect the construction effect and efficiency of the equipment.