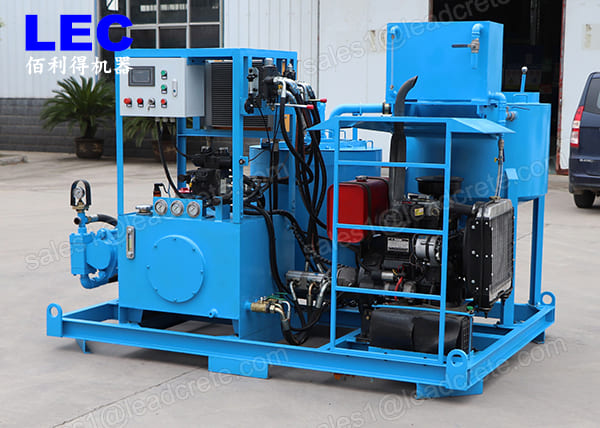

Grouting pump station

The working process of grouting pump station is, put cement water etc. into mixer tank, after completely mixed, then put the slurry to agitator, the slurry in the agitator tank also be mixed in slow speed to avoided sedimentation. The pump’s suction is connected to the outlet of the agitator. Turn on the grout pump to start grouting. The whole process is continuous because of the mixer agitator pump all on one station.

The grouting pump station are driven by hydraulic pressure, with strong power, small size, convenient operation and small floor space. The vortex mixer ensures uniform and rapid mixing. Quickly mix water, cement and other media into a uniform slurry. The mixed slurry is then transferred to a mixer. The slurry pump is injected from the mixing tank. This ensures continuous mixing and grouting operations. The cement slurry mixing equipment is suitable for the cement slurry injection of cement and ultra-fine cement, and the bentonite suspension is used for micro-tunnels, pipe jacking and directional drilling. The grouting and mixing equipment is ergonomic and saves space. The mixing station can also be separated from the unit and used alone.