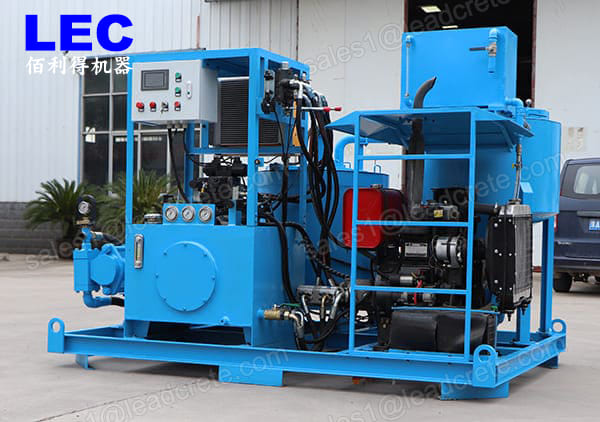

grouting plant for ground anchors

A Grouting Plant for Ground Anchors is a specialized system designed to efficiently and effectively inject grout into the ground for the installation and stabilization of ground anchors. These plants play a vital role in geotechnical engineering projects, ensuring the secure anchorage necessary for slopes, retaining walls, bridges, and tall structures.

Contact Us

Get Price

Share:

Content 2024-05-09

Key features and functionalities of grouting plant for ground anchors include:

Core Components and Functions:

- High-Pressure Capability: Equipped to generate and maintain the high pressures required to penetrate and fill the boreholes accurately, ensuring a strong bond between the anchor and surrounding soil or rock.

- Continuous Mixing and Pumping: Integrates a continuous mixer and a powerful grout pump, allowing for the uninterrupted supply of freshly mixed grout to the injection point. This is crucial for maintaining the consistency and effectiveness of the grout during the entire installation process.

- Accuracy and Control: Provides precise control over the grout mix ratio, flow rate, and pressure, ensuring the grout’s properties meet the specific requirements of each project and anchor type. This is often achieved through computerized control systems for enhanced accuracy.

- Versatile Grout Handling: Capable of handling a variety of grout types, including cementitious, resin, and chemical grouts, making it adaptable to different soil conditions and project needs.

- Rapid Deployment and Setup: Designed for quick assembly and disassembly, allowing for efficient mobilization between job sites. This is especially important in remote or hard-to-access locations.

- Environmental Considerations: Incorporates features to minimize environmental impact, such as dust suppression systems and the ability to manage waste materials responsibly.

- Safety Features: Includes safety mechanisms like emergency stop buttons, pressure relief valves, and protective guarding around moving parts to ensure operator safety during high-pressure operations.

Applications in Ground Anchor Installations:

- Slope Stabilization: For reinforcing unstable slopes, preventing landslides, and supporting retaining walls.

- Bridge and Infrastructure Foundations: To provide additional stability and support to deep foundations and anchorages.

- Tunneling Support: In tunnel construction, for securing tunnel linings and providing ground support.

- Building Foundations: Enhancing the load-bearing capacity of foundations in soft or variable soil conditions.

- Offshore Structures: For anchoring offshore platforms and wind turbines to the seabed.

Inquiry

More Grout Plant