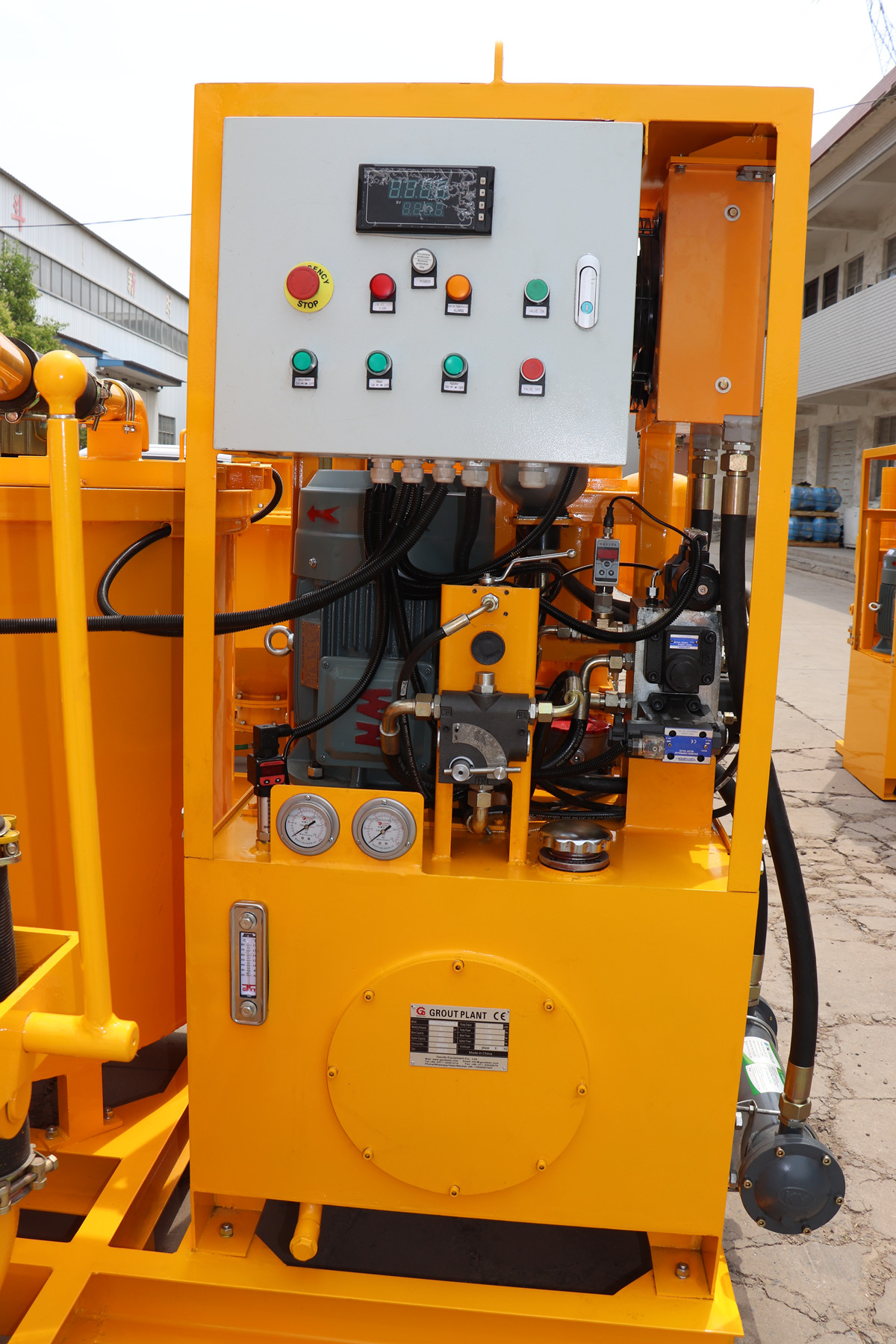

Grouting cement plant

Grouting cement plant is specially designed for mortar mixing and mortar injection. Grouting cement plant integrates a mixer, a double mixer, and a mortar pump, and is mainly used for ground/underground construction such as highways, railways, hydropower, buildings, and mines.

We can mix water and cement through a high-speed vortex mixer for about 2 to 3 minutes, and then we rotate the conveyor switch to deliver the cement slurry to the No. 1 mixer. At this time, the sand that has been screened can be added to the No. 1 mixer. After the sand and cement are evenly mixed, open the discharge port to discharge the mortar from the No. 1 agitator to the No. 2 agitator, and then start the mortar pump to suck the mortar from the No. 2 agitator.

This ensures continuous mixing and grouting operations. According to the requirements of grouting, we can control the displacement of the grouting pump through the frequency converter. The grouting displacement of grouting cement plant is steplessly adjustable.