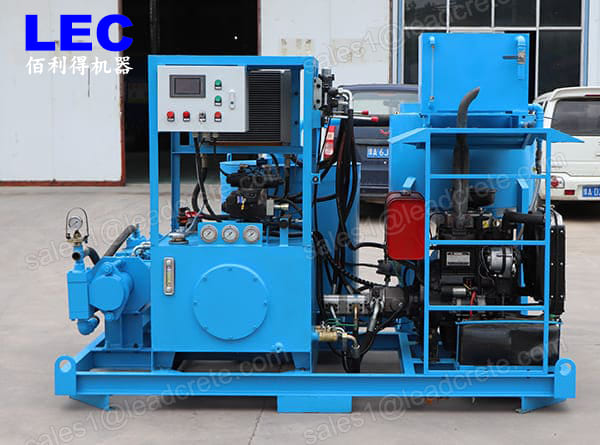

Grout mixing plant with plunger pump

Grout mixing plant is responsible for preparing, storing, and delivering grout mixes. It typically includes:

Mixing Tank: A container where all the grout ingredients (cement, water, sand, if required, and admixtures) are combined to form a homogeneous mixture. Agitation ensures that the mix remains consistent and free of lumps.

Agitator: Continuously stirs the mixture to prevent separation and settling of particles.

Additive Dispensing System: Automatically or manually adds necessary admixtures to enhance the properties of the grout, such as plasticizers for improved flow or accelerators to speed up curing.

A Grout mixing plant with plunger pump is a device used for preparing and mixing grouting materials, with the plunger pump being one of its core components. The following is a clear answer about this device:

Function: This device is mainly used to mix cement, additives and other raw materials into grouting materials, and transport the mixed materials to the areas that need reinforcement or filling through a plunger pump.

Working principle: The plunger pump changes the volume of the chamber through the reciprocating motion of the plunger in the pump cylinder, achieving the suction and extraction of liquid. This pump structure can provide high pressure and stable flow, ensuring that the grouting material can be effectively injected into the target area.

Types: Plunger pumps can be classified into various types based on different designs and requirements, such as single plunger pumps, double plunger pumps, etc. These pump types vary in flow rate, pressure, and efficiency, and can be selected according to specific engineering requirements.

Mixing capacity: For example, the mixing capacity of certain models of Grout mixing plants can reach 200L or larger, which determines the amount of grouting material that can be prepared each time.

Mixing yield: The mixing yield of the equipment is also an important parameter, for example, the mixing yield of some equipment can reach 4m ³/h, which represents the volume of grouting material that the equipment can prepare per hour.

Output pressure: The output pressure of the plunger pump is also one of the key parameters, which determines the depth and effectiveness of grouting material injection. For example, the output pressure of some plunger pumps can reach 100 bar or higher.

Other parameters: including circulation capacity (such as 1100L/min), water cement ratio (such as 0.5), etc., all of which directly affect the performance of the equipment and grouting effect.

Efficiency: The efficiency of the plunger pump ensures the rapid preparation and transportation of grouting materials.

Stability: The structural design of the plunger pump enables it to provide stable flow and pressure, ensuring the smooth progress of grouting operations.

Adaptability: The equipment can adjust parameters and formulas according to different engineering needs to adapt to different geological conditions and engineering requirements.

Durability: Equipment manufactured with high-quality materials and advanced technology has high durability and reliability, and can operate stably for a long time in harsh working environments.

This device is widely used in geological engineering, civil engineering, construction engineering and other fields, for reinforcing soil, rock structures, filling gaps, etc. Its efficient, stable, and reliable performance makes it an indispensable tool in these fields.