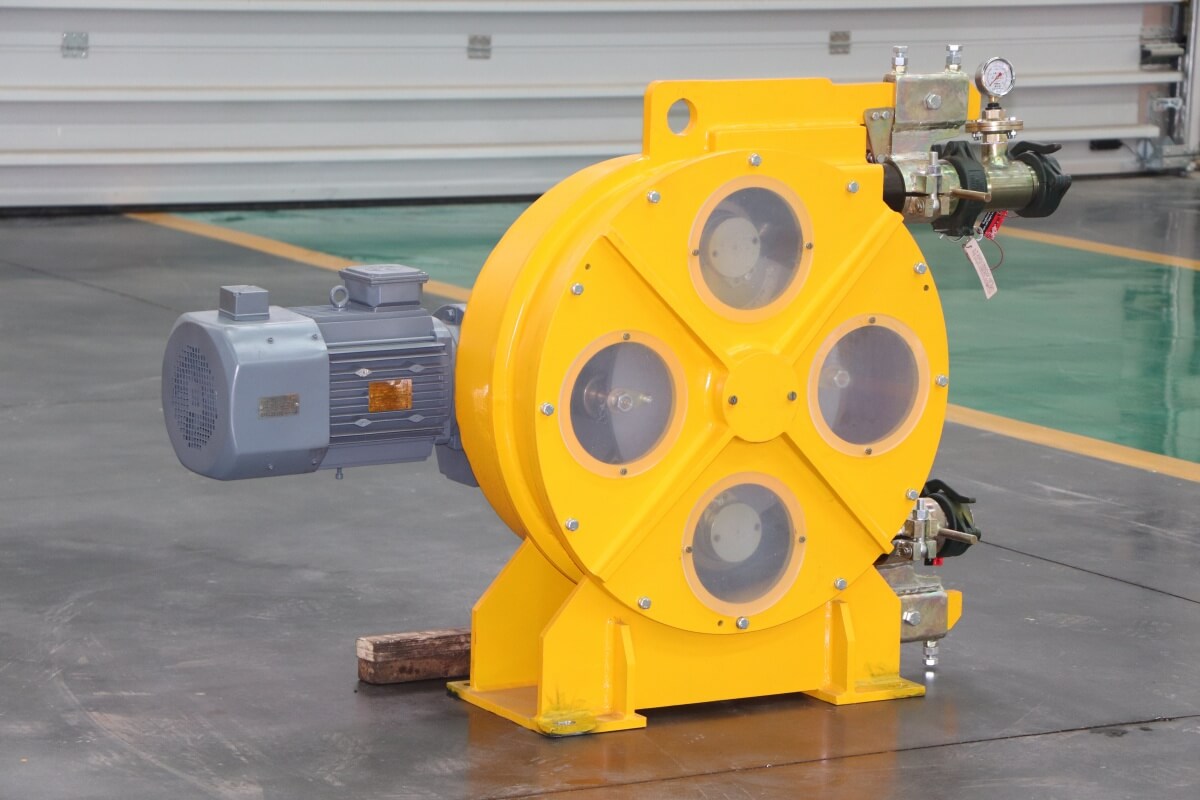

Explosion Proof Peristaltic Squeeze Hose Pump

Explosion Proof Peristaltic Squeeze Hose Pumps are designed to operate safely in hazardous environments where flammable and explosive gases, vapors or dusts are present. These pumps are commonly used in industries such as petrochemicals, pharmaceuticals, food processing, coatings and solvent handling to ensure that there is no fire or explosion when transferring potentially explosive media.

Explosion Proof Peristaltic Squeeze Hose Pump, also known as explosion-proof peristaltic squeeze hose pump, is a special pump device that combines the peristaltic pump principle with explosion-proof characteristics.

1. Explosion proof peristaltic squeeze hose pump structure and working principle

Structure:

The pump is mainly composed of a pump body, a hose, a drive device and an explosion-proof device.

The pump body is usually made of solid metal materials and has good explosion-proof performance.

As the core component of the pump, the hose is responsible for conveying the fluid under the squeeze of the drive device.

The drive device provides power through a motor or pneumatic means, so that the hose is squeezed and relaxed periodically to achieve fluid delivery.

The explosion-proof device is used to prevent the generation of sparks or arcs during the operation of the pump to ensure safety in flammable and explosive environments.

Working principle:

When the drive device is started, it will squeeze the hose periodically, causing the fluid in the hose to flow out under pressure.

During the squeezing process, the hose will temporarily deform and recover, forming a continuous conveying process.

Since the squeezing and relaxation of the hose are periodic, the output flow of the pump is also pulsed. However, by adjusting the speed and extrusion frequency of the drive device, the flow rate can be precisely controlled.

2. Features and advantages of explosion proof peristaltic squeeze hose pump

Explosion-proof performance:

The pump uses special explosion-proof devices and materials, which can operate safely in flammable and explosive environments.

Its explosion-proof level is usually high and can meet the use requirements of various hazardous places.

Strong self-priming ability:

Since the hose forms a negative pressure area during the extrusion process, the pump has a strong self-priming ability.

This allows it to achieve self-priming and delivery of fluids without an additional suction device when conveying fluids.

Accurately adjustable flow:

By adjusting the speed and extrusion frequency of the drive device, the output flow of the pump can be precisely controlled.

This gives the pump a great advantage in occasions where precise control of the flow rate is required.

Wide range of conveying fluids:

The pump can convey various types of fluids, including high viscosity, corrosive, flammable and explosive fluids.

This makes it widely used in many fields such as chemical, petroleum, pharmaceutical, food, etc.

Easy maintenance:

The structure of the pump is relatively simple, and the hose is easy to replace as a wearing part.

This reduces maintenance costs and downtime, and improves the reliability and service life of the equipment.

3. Application fields of peristaltic squeeze hose pump

Due to its unique structure and characteristics, explosion-proof peristaltic extrusion hose pumps are widely used in the following fields:

Chemical industry: used to transport various corrosive, flammable and explosive chemical raw materials and products.

Petroleum industry: used to transport flammable and explosive fluids such as oil and natural gas.

Pharmaceutical industry: used to transport biological products such as liquid medicine and vaccines to ensure the quality and safety of medicines.

Food industry: used to transport food raw materials such as jam, juice, and dairy products to ensure food safety and hygiene.

Other industries: such as environmental protection, metallurgy, textiles and other industries also have wide applications.