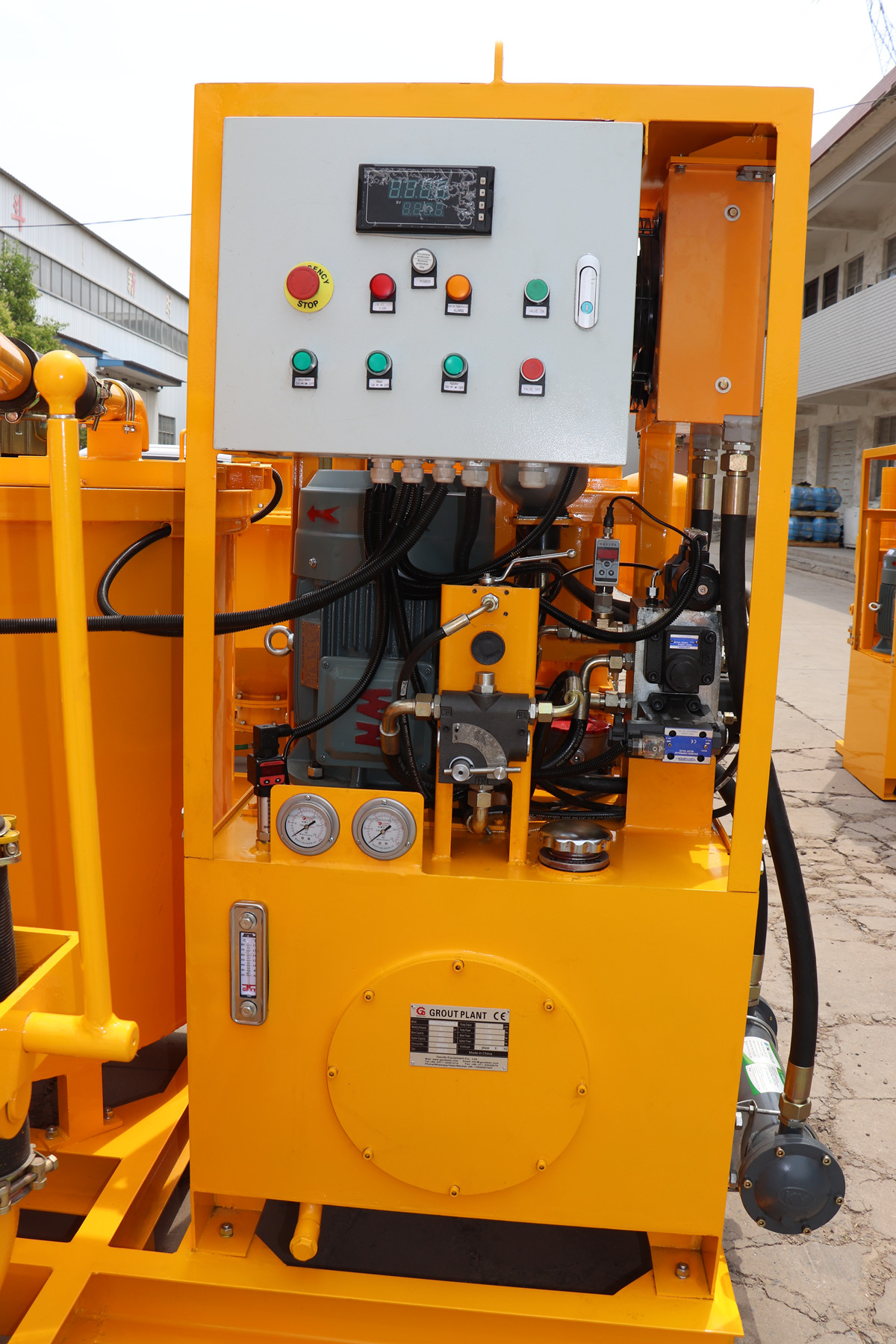

Electric motor grout plant

An electric motor grout plant is a modern and efficient piece of equipment used in construction and civil engineering for precise and effective grouting applications. This type of grout plant utilizes an electric motor to drive the various components, offering several advantages over traditional systems.

Here’s an in-depth look at its features and benefits:

- Electric Motor Drive: The electric motor provides a reliable and consistent power source for the grout plant. This results in smoother operation, reduced noise levels, and lower emissions compared to diesel or gas-powered alternatives. The electric motor also ensures energy efficiency, leading to lower operational costs.

- High-Performance Mixing and Pumping: The grout plant includes a high-performance mixer and pump. The mixer efficiently blends water, cement, and other additives into a homogenous grout mixture. The pump, driven by the electric motor, ensures a steady and controlled flow of grout, suitable for various applications such as soil stabilization, structural repairs, and rock grouting.

- User-Friendly Design: The electric motor grout plant is designed with ease of use in mind. It features intuitive controls and clear indicators that allow operators to easily monitor and adjust the grouting process. The electric motor provides smooth start-up and operation, minimizing the risk of mechanical issues and ensuring a reliable performance.

- Versatility and Adaptability: This type of grout plant is versatile and can handle a wide range of grouting materials, including cementitious grouts, chemical grouts, and epoxy grouts. Its adaptability makes it suitable for various construction applications, from large infrastructure projects to detailed repair work.

- Environmentally Friendly: Utilizing an electric motor reduces the environmental impact of the grout plant. It produces fewer emissions and operates more quietly than combustion engine alternatives, making it a better choice for projects in urban areas or sensitive environments.

- Low Maintenance and Long Lifespan: The electric motor and associated components are designed for durability and long service life. Maintenance requirements are typically lower than those for combustion engines, resulting in reduced downtime and lower maintenance costs. Regular checks and servicing ensure the plant remains in optimal working condition.

In summary, an electric motor grout plant offers numerous benefits, including energy efficiency, high performance, user-friendly operation, and environmental friendliness. Its robust construction and versatile capabilities make it an ideal choice for a wide range of grouting applications in construction and civil engineering. Investing in an electric motor grout plant can enhance the efficiency, quality, and sustainability of your grouting projects.