dry shotcrete swimming machine

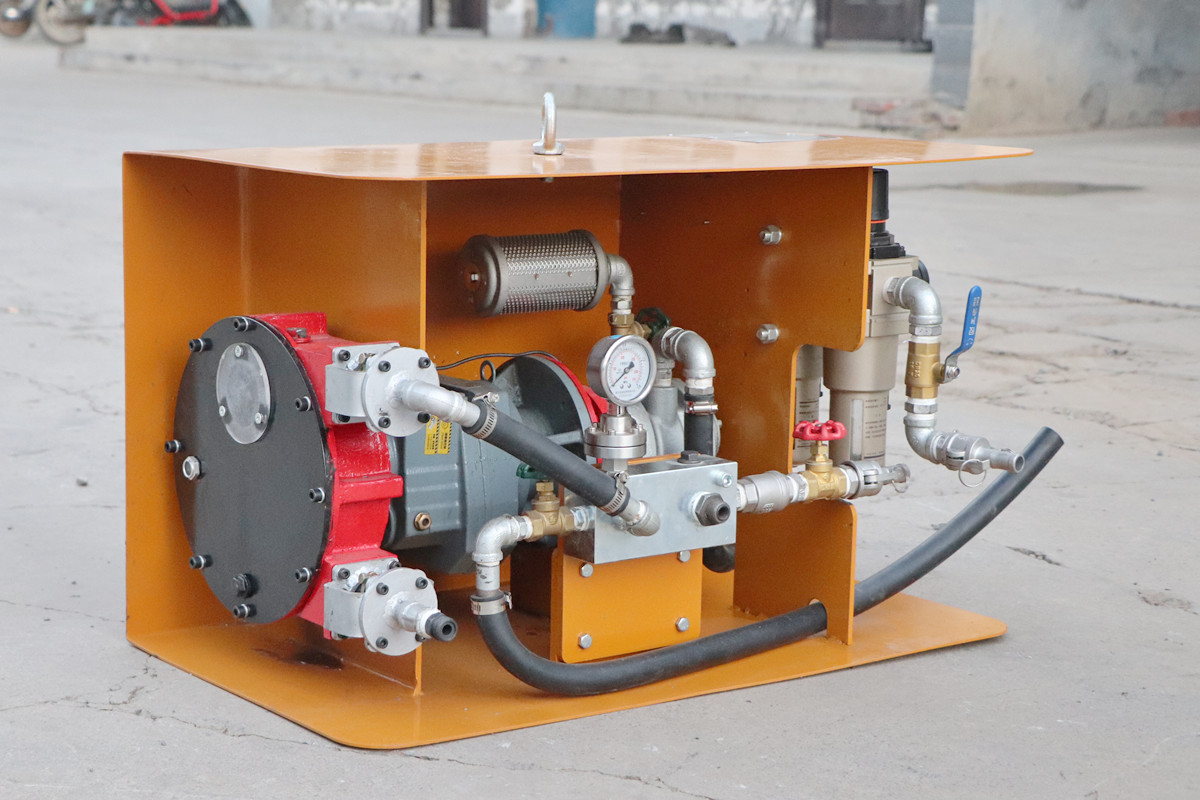

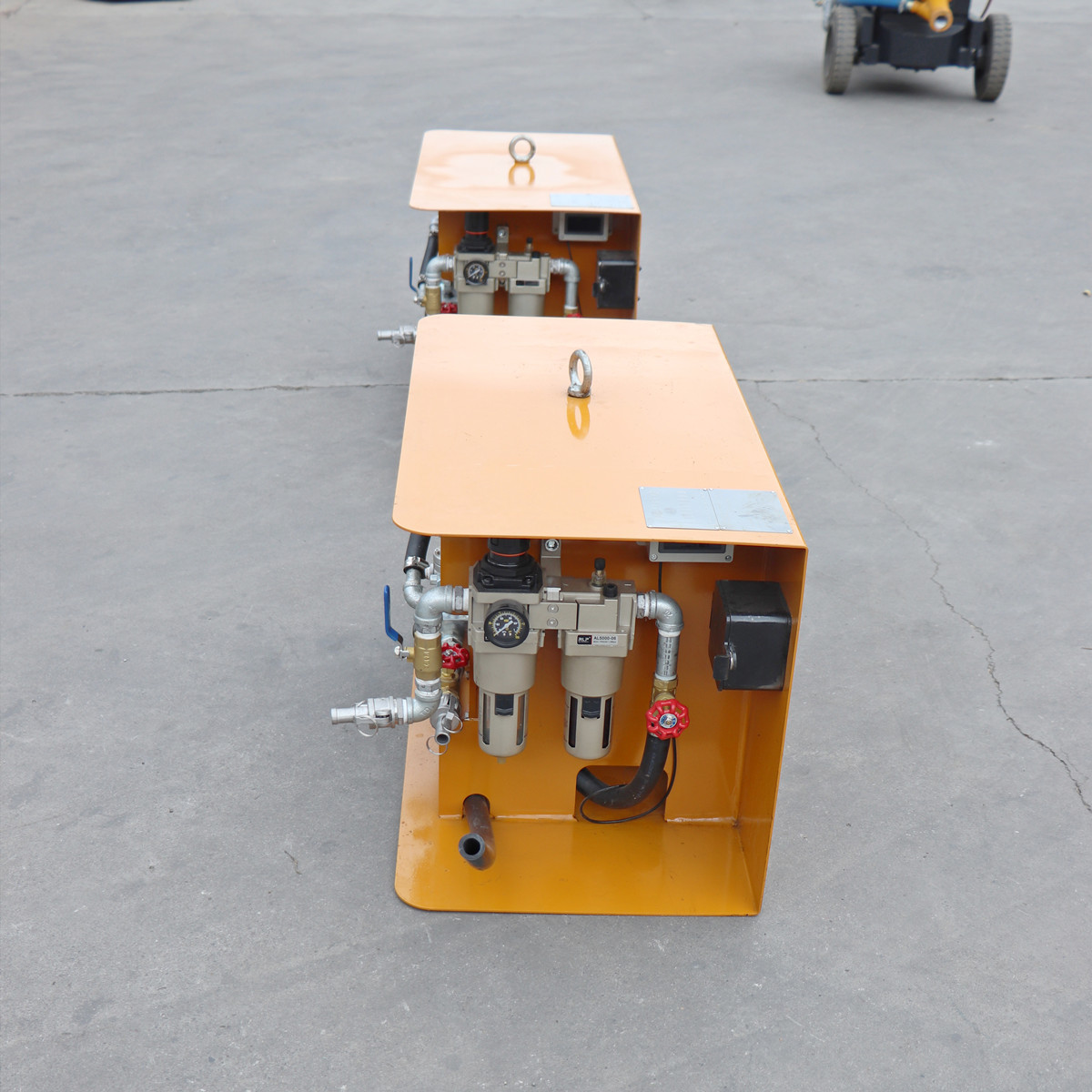

The dry shotcrete swimming machine because of the addition of dry concrete or cement, so the jet, the nozzle need to add water to ensure that the spray effect and will not produce too much dust.

The dry shotcrete swimming machine has the following advantages:

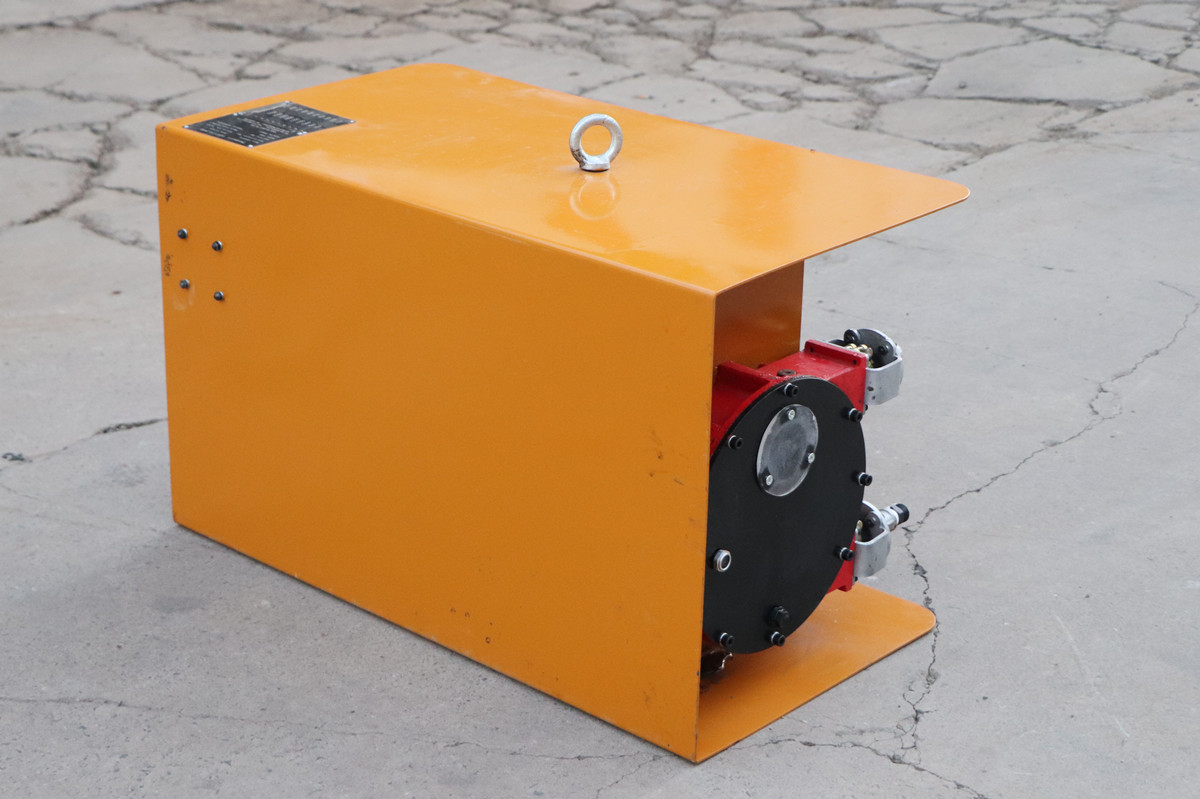

High effective concrete spraying working, Easy operation, Stable performance; Rotor Disk: There are two rotor disks on the opposite sides of rotor, it is made of high-qualified alloy steel and can handle concrete more than 4000m3 during its working Period. Rubber Sealing Plate: There are two plates upper and lower. Both of the upper and lower plates are made of anti-abrasive special rubber and can handle concrete 300-400m3 during its working period. Clamping Device: By this device, the force is acted through the screws and cylindrical springs, which works as elastic auto-clamping device. Tight clamping by the turnover frame floating can provide a constantly uniform pressure at the sealing surfaces with a high tightening effect and low dust emission, and can avoid rubber plate over-worn, too. Thin flow conveying method with vortex flow, so the spraying flow is even, continuous and steady, to improve the shotcrete quality.