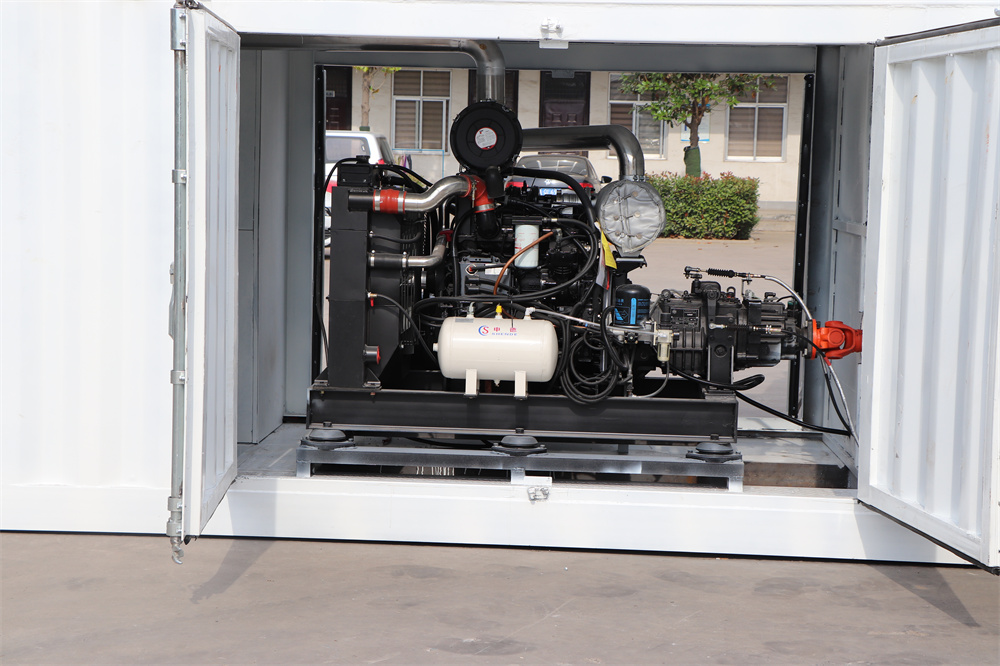

Diesel jet grouting pump in container

The diesel jet grouting pump in container is a powerful and versatile tool for ground improvement projects. Powered by a diesel engine with a 10-speed gearbox and pneumatic clutch, it is designed for high pressure grout injection and jet grouting systems. It is particularly suitable for complex accumulation of water or casing that requires targeted treatment, making it an excellent choice for bracing, water control, soil stabilization and other geotechnical challenges.

One of the most attractive features of the diesel jet grouting pump is its versatility. It works on a wide variety of soil types, including silt, sand, and most clays. This makes it one of the most adaptable techniques available, able to handle a wide range of geotechnical challenges.

In addition, jet grouting can construct a variety of geometries, including thin vertical panels, fan-shaped (partial) columns, and full columns of varying diameters. By controlling various grouting parameters such as drill pipe extraction speed, rotation speed, grout pumping pressure, grout flow rate, and grout specific gravity, the properties of the cement soil can be altered, including strength and hydraulic conductivity.

Diesel jet grouting pumps in containers are used in a variety of fields, including highway, railway, mine, port, and national defense, for foundation reinforcement, construction settlement control, foundation impermeable curtain, retaining soil cofferdam, slope anchoring, mine plugging, wellbore retaining walls, and other engineering requirements. The size of the equipment can also be adjusted according to project needs, from low headroom applications to processing depths in excess of 100 feet. This flexibility makes the technology adaptable to meet the specific requirements of each project.