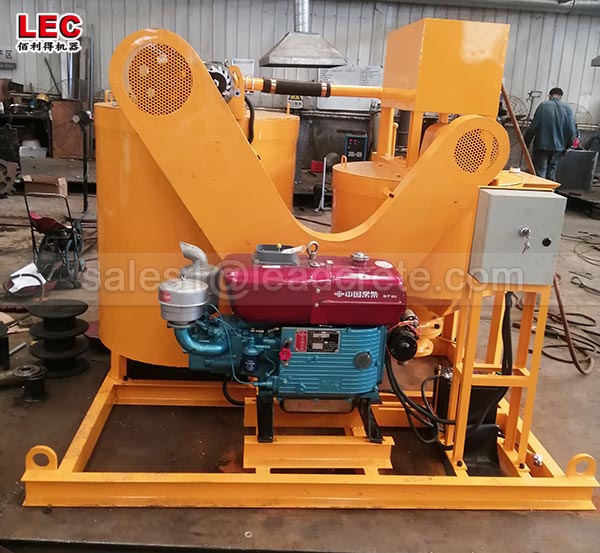

diesel high shear colloidal mixer

Diesel high shear colloidal mixer is a combination of mixer and agitator, it is specially designed for continuous cement mixing and grouting in ground/underground engineering.

Contact Us

Get Price

Share:

Previous:

200L high speed grout mixer

Next:

Grout mixer for drill

Content 2022-04-18

Diesel high shear colloidal mixer is widely used for construction, such as dam foundation grouting, and tunnel grouting. The mixing time to produce thoroughly mixed neat cement grout with high shear grout mixer just takes about 1-2 minutes.

Inquiry

More Grout Mixer